Efficient amoxil capsule screening device

A technology of amoxicillin capsules and screening devices, which is applied in the field of high-efficiency amoxicillin capsules screening devices, can solve the problems of low efficiency, consumer loss, and affecting the reputation of capsules, so as to achieve uniform feeding, ensure quality, and avoid capsules. stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

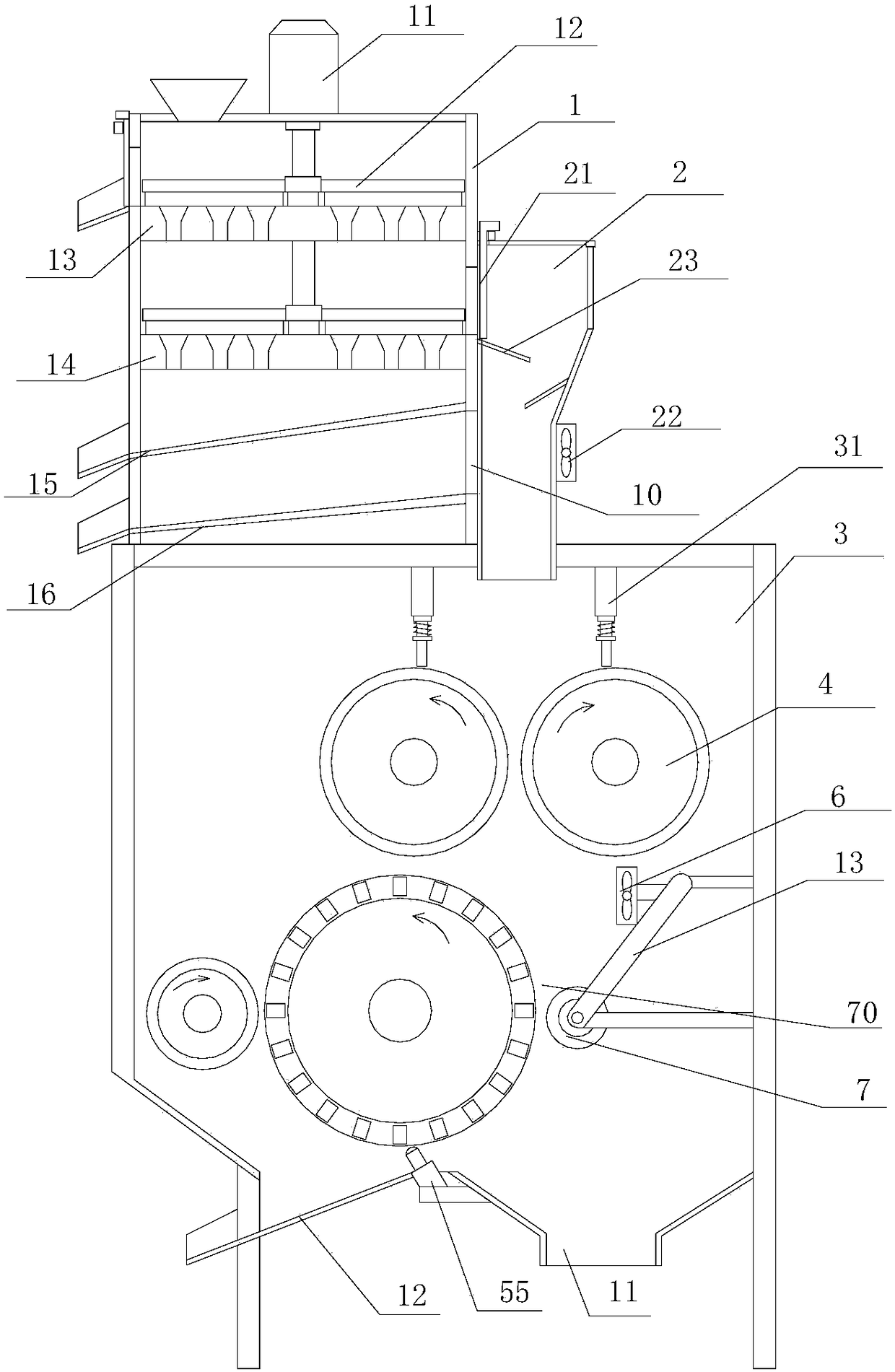

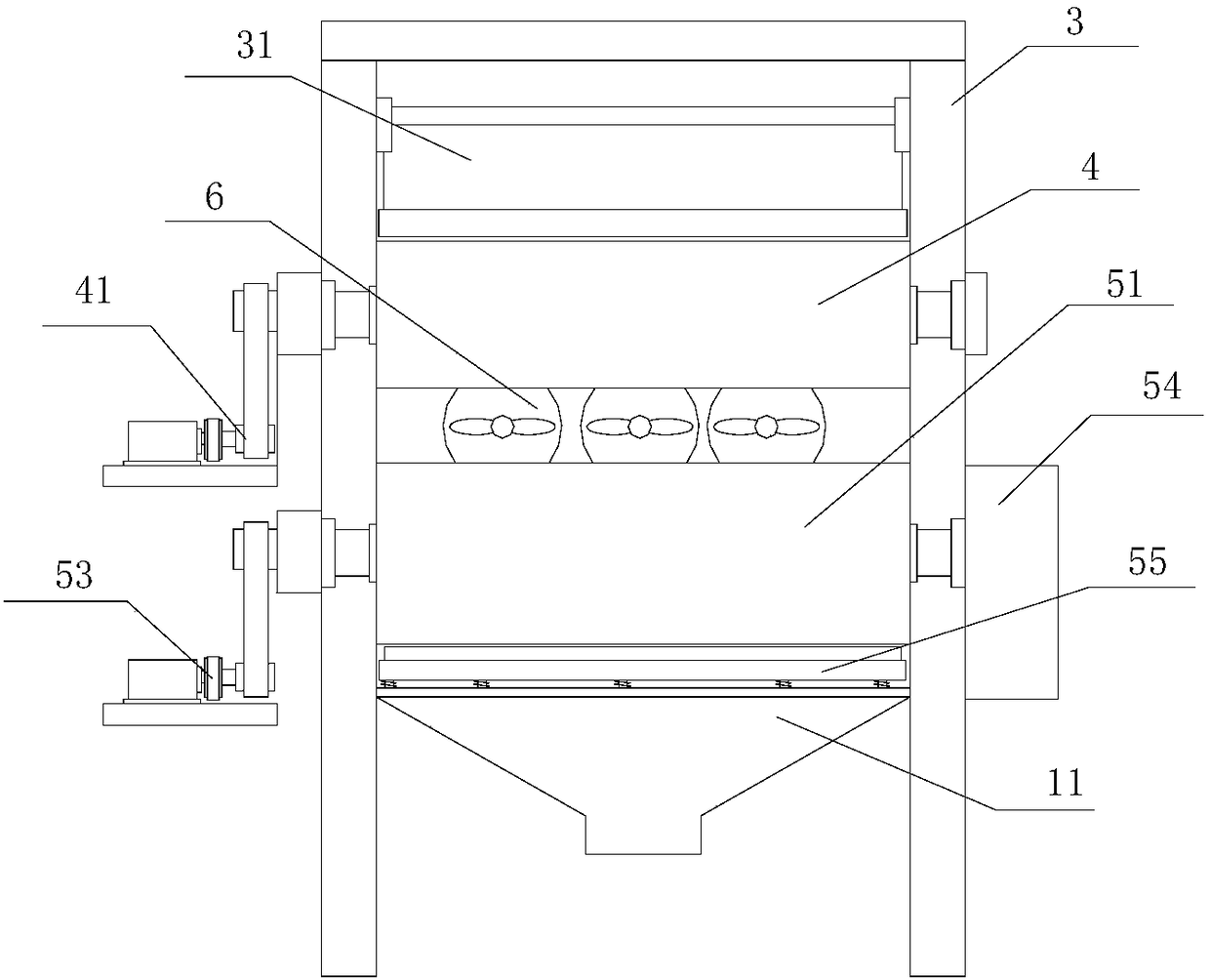

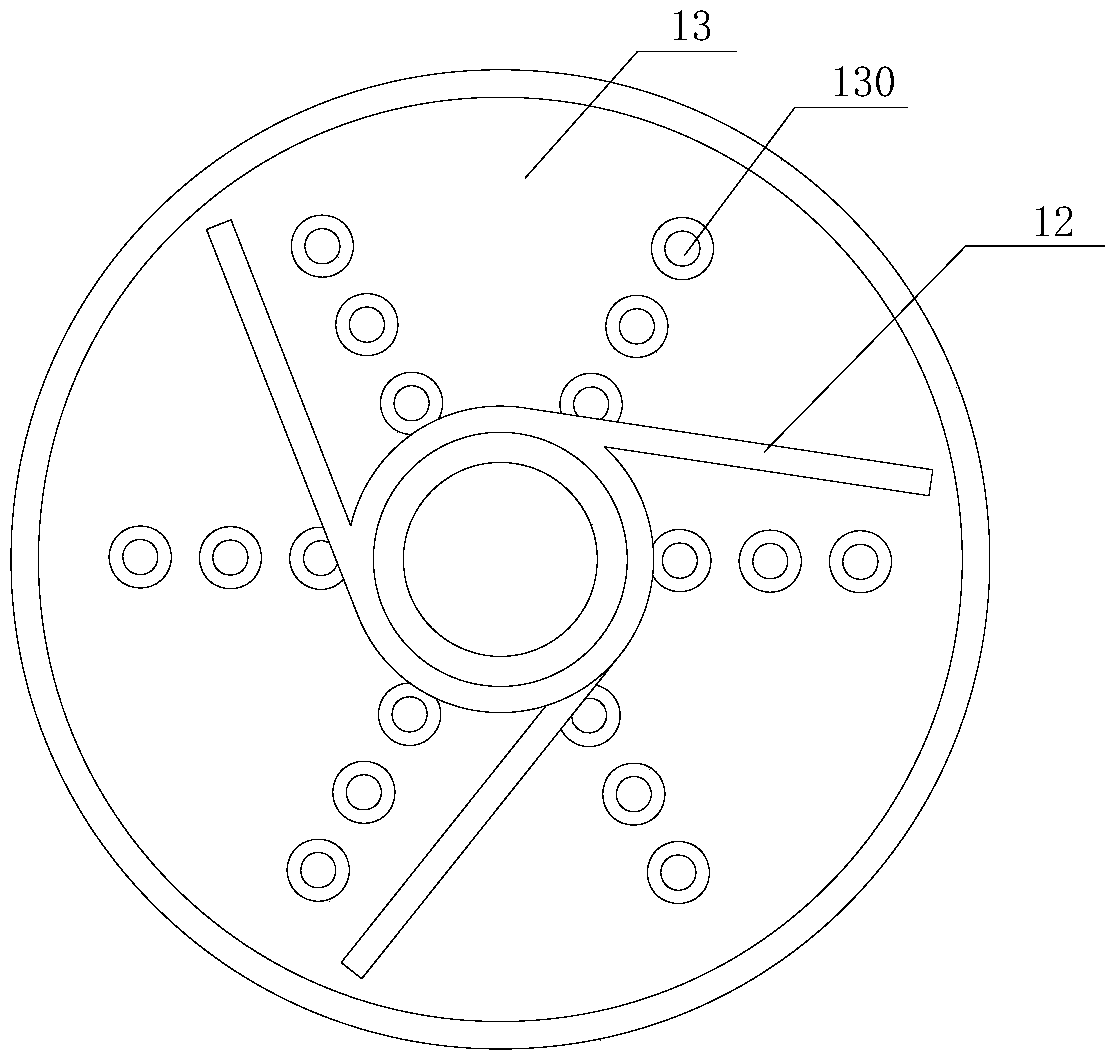

[0016] refer to Figure 1 to Figure 4 A high-efficiency amoxicillin capsule screening device of the present invention comprises a screening mechanism 1, a primary rejecting mechanism 2, a secondary rejecting mechanism 3, a material feeding brush roller assembly 4, a material removing mechanism 5, a second blower 6 and a feeding The brush roller assembly 7, the screening mechanism 1 is provided with a primary screening plate 13 and a secondary screening plate 14, the top of the primary screening plate 13 and the secondary screening plate 14 is provided with a driving brush rod 12, the The side wall of the screening mechanism 1 is provided with a first-level rejecting mechanism 2, and a plurality of shunt sealing partitions 23 are arranged in the first-level rejecting mechanism 2, and a first air blower 22 is provided on the side wall of the first-level rejecting mechanism 2. The bottom of the primary rejecting mechanism 2 is provided with two feeding brush roller assemblies 4, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap