Gas-assisted continuous casting extrusion method and device

A gas-assisted and inert gas technology, applied in the field of gas-assisted continuous casting and extrusion, can solve the problems of unevenness, shortening the process flow, and limitation, and achieve the effects of excellent material structure and performance, shortening the process flow, and reducing the stacking length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

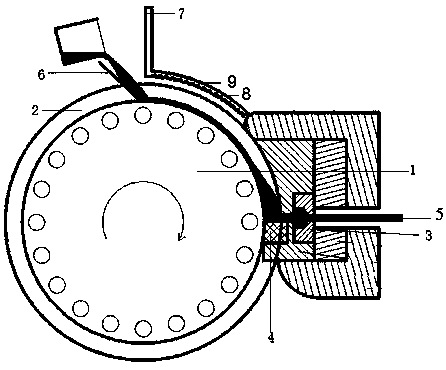

[0019] The device used in this example is figure 1 As shown, the device mainly includes an extrusion wheel 1, an extrusion wheel groove 2, a mold 3, and a plug 4. A deflector 6 and a gas cooling device 9 are provided on a common continuous extrusion device. The top of the pressure wheel groove 2 extends obliquely into the squeeze wheel groove 2; the gas cooling device 9 includes an air inlet 7 and a nozzle 8, one end of the air inlet 7 is connected to the gas bottle, and the other end is connected to the nozzle 8; the nozzle 8 A plurality of air outlets are evenly opened on one side close to the extrusion wheel groove 2 .

[0020] Taking the Al-25Si alloy bar material as an example below, the method of the present invention is further described in detail in conjunction with the device, the method is as follows:

[0021] (1) Ingredients: Prepare Al 75% and Si 25% according to the mass percentage to prepare the raw materials;

[0022] (2) Melting: Put the prepared aluminum-sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com