Solid rocket ramjet air inlet way machining method

A ramjet and solid rocket technology, applied in ramjet engines, engine components, combined engines, etc., can solve problems such as poor control of stress, poor precision, and excessively long welds, so as to shorten processing time and reduce production Cost, the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

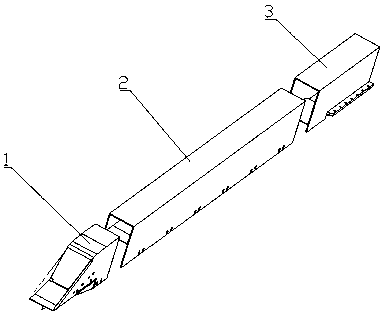

[0023] like Figure 1~2 Shown, a kind of solid rocket ramjet motor inlet processing method comprises the following steps:

[0024] (a) According to the different processing accuracy of different position sections, the intake duct is divided into three independent parts: the front section 1, the middle section 2, and the tail section 3.

[0025] (b) Carry out the processing of the front section 1 and the tail section 3. The processing method is: assemble the plates into the designed structural shape of the front section 1 and the tail section 3, and then weld them to form the front section 1 and the tail section 3 respectively. Afterwards, finish machining of the inner surface of the inner flow channel of the front section 1 and the tail section 3 (machining accuracy is Ra≤1.6), and finishing of the outer surface (machining accuracy is Ra≤3.2).

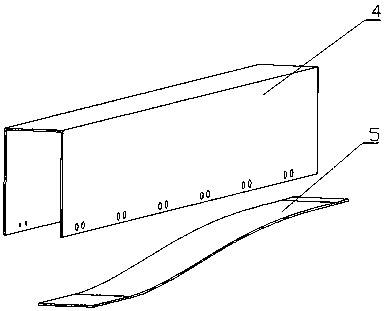

[0026] (c) Process the middle section 2, which consists of two parts, including the door-shaped housing 4 and the bottom plate 5. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com