Laser ranging sensing based blank allowance automatic detection device and method

An automatic detection device, laser ranging technology, applied in automatic control devices, feeding devices, measuring/indicating equipment, etc., can solve the problems of increasing equipment costs, reducing production efficiency, increasing workpiece transfer, etc., to improve automation and improve qualification. rate, reduce the effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

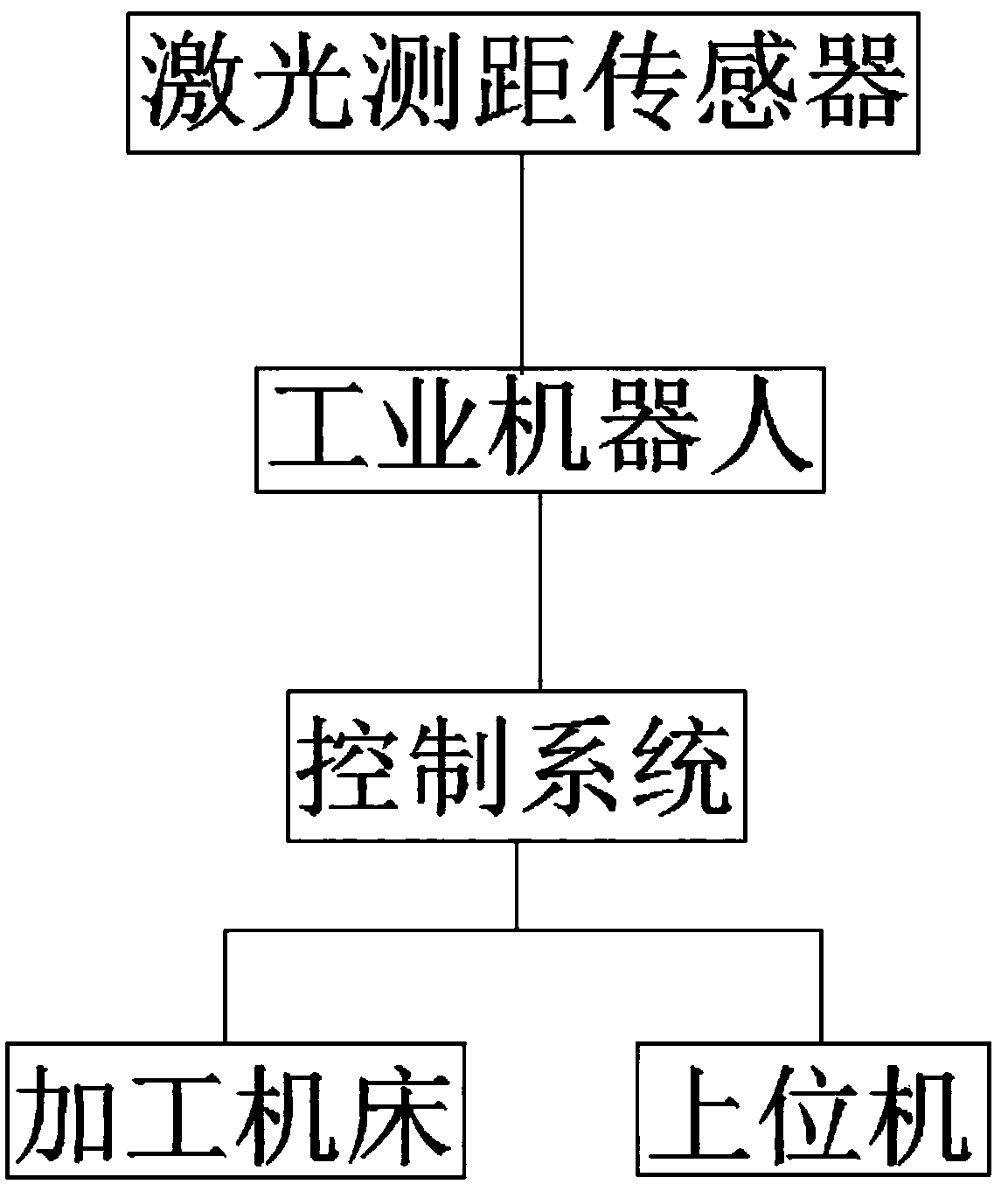

[0032] Attached below figure 1 The present invention is described further:

[0033] An automatic blank margin detection device based on laser ranging sensing, including a special fixture for positioning a workpiece, a laser ranging sensor for detecting the size of the workpiece, the laser ranging sensor is installed on an industrial robot, and the industrial robot The control system is connected to the processing machine tool and the upper computer; the special fixture is located at the blank allowance detection station or installed on the machine tool; the upper computer is a server or an industrial computer; the detection accuracy of the detection system is ±0.3mm.

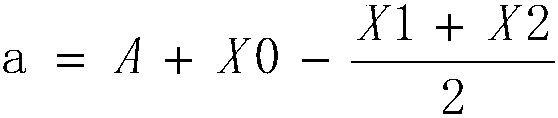

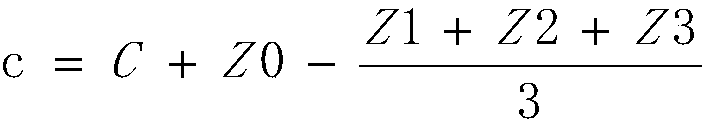

[0034] The blank margin detection system is mainly composed of an industrial robot, a laser distance measuring sensor, a control system and a host computer. The workpiece blank is automatically or manually installed in the fixture according to the designed positioning method. After the workpiece is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com