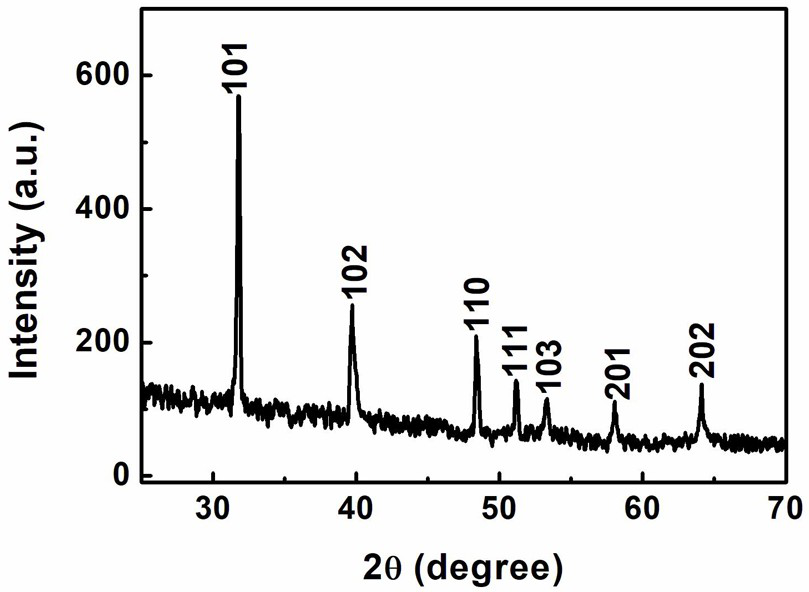

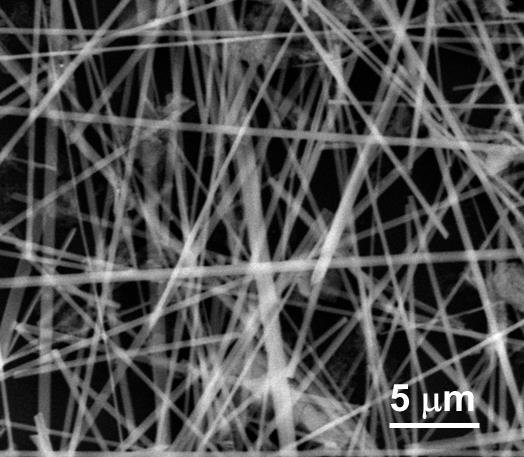

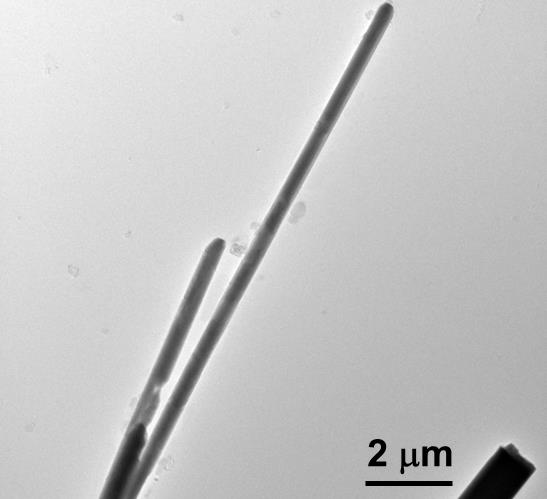

A kind of method for preparing tin diselenide nanowire at low temperature

A technology of tin diselenide and nanowires, applied in binary selenium/tellurium compounds, nanotechnology, metal selenide/telluride, etc., can solve problems such as toxic pollutants, complex synthesis process, etc., and achieve easy surface modification , the operation procedure is simple, the synthesis cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The concrete synthesis method of tin diselenide nanowire material: the raw material of synthesizing tin diselenide nanowire material is ethanol, hydrazine hydrate, tin tetrachloride, sodium selenite, ammonia water, and the reaction that takes place is as follows:

[0020]

[0021] The specific operation steps are as follows:

[0022] Step 1, by weight percentage, ethanol is 40% and hydrazine hydrate is 60% and is weighed and mixed as a reaction solvent.

[0023] Step 2, weighing 40% by weight of tin tetrachloride and 60% by weight of sodium selenite as reactants.

[0024] Step 3, preparing an ammonia solution, by dissolving the ammonia solution in an appropriate amount of water so that the final pH value is 8-10.

[0025] Step 4, heating the reaction, taking the reaction raw materials and reaction solvent added to the reaction vessel as the total weight, the reaction raw materials with a weight percentage of 0.5% and the reaction solvent with a weight ratio of 99.5%...

Embodiment 2

[0029] The raw materials for synthesizing tin diselenide nanowire materials are ethanol, hydrazine hydrate, tin tetrachloride, potassium selenite, and ammonia water, and the reactions that take place are as follows:

[0030]

[0031] The specific operation steps are as follows:

[0032] Step 1, 60% ethanol and 40% hydrazine hydrate are weighed and mixed as a reaction solvent by weight percentage.

[0033] Step 2, weighing 60% by weight of tin tetrachloride and 40% by weight of potassium selenite as reactants.

[0034] Step 3, preparing an ammonia solution, by dissolving the ammonia solution in an appropriate amount of water so that the final pH value is 8-10.

[0035] Step 4, heat the reaction, take the reaction raw materials and reaction solvent added to the reaction vessel as the total weight, prepare the reaction raw materials with a weight percentage of 10% and the reaction solvent with a weight ratio of 90%, and put the noble metal inert to the reaction solution toget...

Embodiment 3

[0039] The raw materials for synthesizing tin diselenide nanowire materials are ethanol, hydrazine hydrate, tin tetrachloride, potassium selenite, and ammonia water, and the reactions that take place are as follows:

[0040]

[0041] The specific operation steps are as follows:

[0042] Step 1, 50% by weight of ethanol and 50% of hydrazine hydrate are weighed and mixed as a reaction solvent.

[0043] Step 2, weighing 50% by weight of tin tetrachloride and 50% by weight of potassium selenite as reactant.

[0044] Step 3, preparing an ammonia solution, by dissolving the ammonia solution in an appropriate amount of water so that the final pH value is 8-10.

[0045] Step 4, heat the reaction, take the reaction raw materials and reaction solvent added to the reaction vessel as the total weight, prepare the reaction raw materials with a weight percentage of 5% and the reaction solvent with a weight ratio of 95%, and put the noble metal inert to the reaction solution together Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com