Gas power device and method

A technology of gas power and gas pipes, which is applied in the direction of gas turbine devices, turbine/propulsion device inlets, turbine/propulsion device fuel flow channels, etc., and can solve problems such as reduced technical and economic performance, increased irreversible losses, and reduced system efficiency , to achieve the effects of small structure size, reduction of NOX compound emissions, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

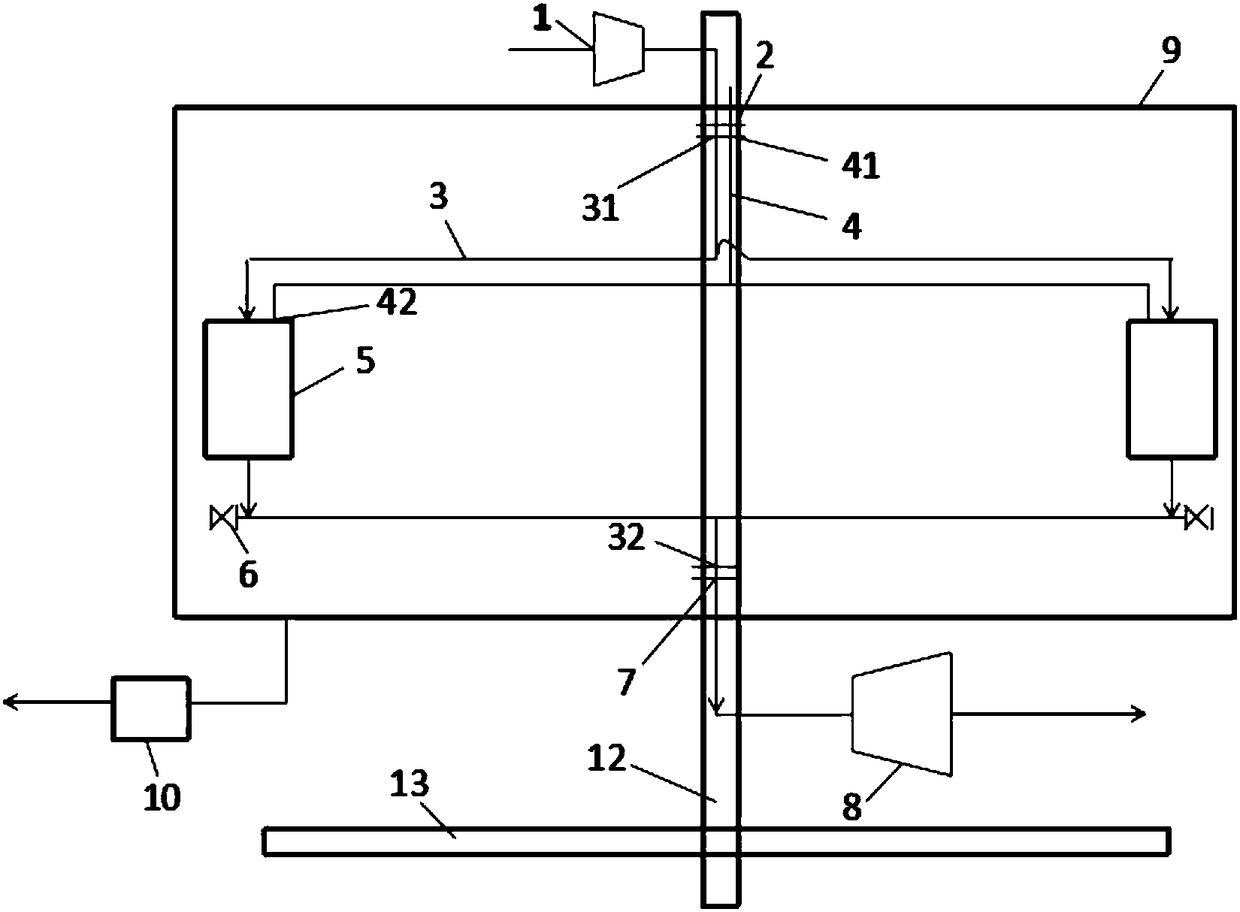

[0052] Embodiment 1, gas powered device, such as figure 1 As shown, it includes a blower 1, a rotary joint, a turbine 8, an air pipe 3, an oil pipe 4, a rotating shaft 12, a protective shell 9, a vacuum pump 10 and an isobaric combustion chamber 5;

[0053] The rotating shaft 12 is fixedly connected with a base 13, and the air blower 1, the turbine 8, the protective casing 9, the vacuum pump 10 and the isobaric combustion chamber 5 are fixed with the base 13, and the base 13 can rotate together with the rotating shaft 12.

[0054] The quantity of gas pipe 3 is one or at least two, and the quantity of oil pipe 4 and equal pressure combustion chamber 5 is all identical with the quantity of gas pipe 3 and corresponds one by one, and each gas pipe 3 is all provided with at least two isothermal combustion chambers 11, and gas pipe 3 and the oil pipe 4 are evenly arranged around the axis position of the rotating shaft 12 as the center.

[0055] The air pipe 3 is provided with an ai...

Embodiment 2

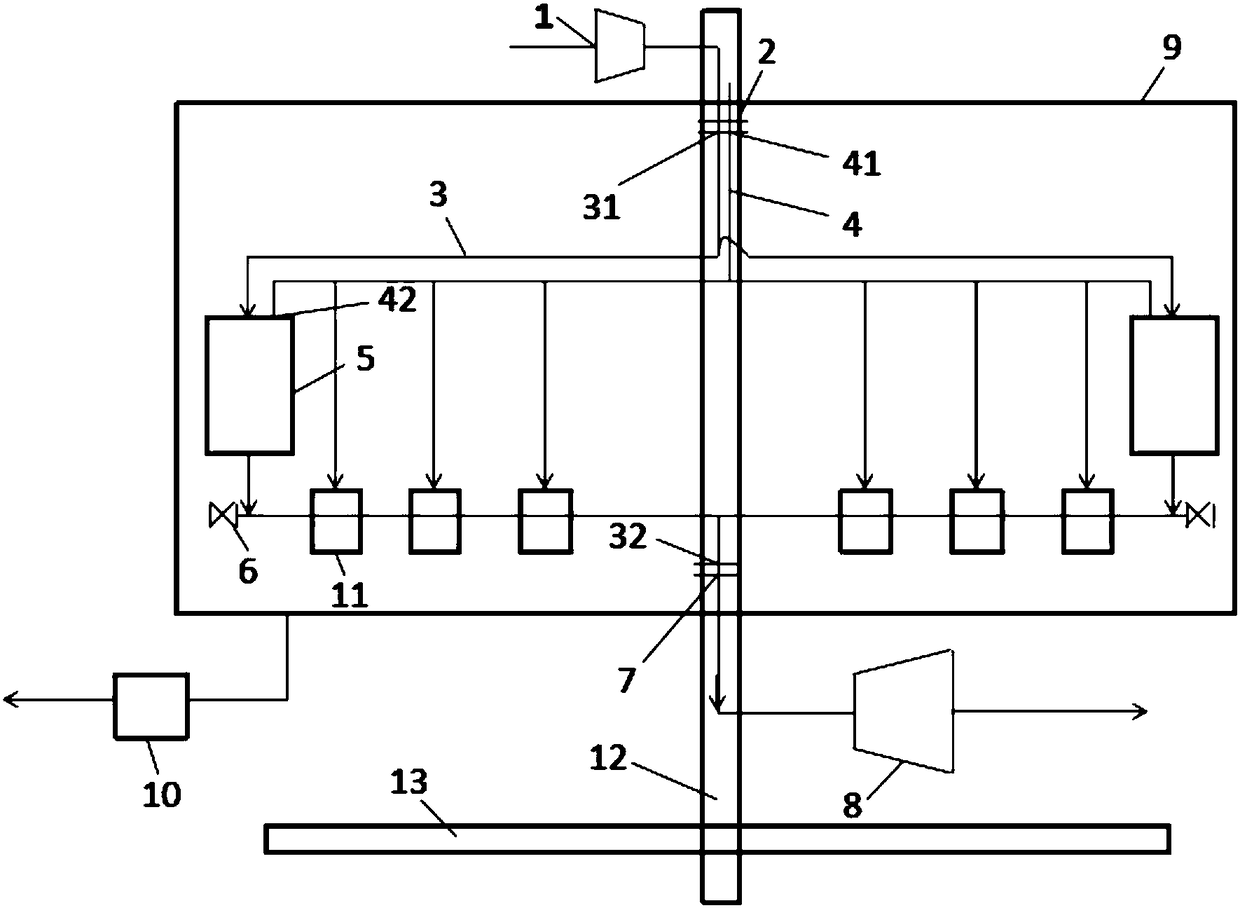

[0071] Embodiment 2, gas powered device, such as figure 2 As shown, it includes a blower 1, a rotary joint, a turbine 8, an air pipe 3, an oil pipe 4, a rotating shaft 12, a protective shell 9, a vacuum pump 10, an isobaric combustion chamber 5 and an isothermal combustion chamber 11.

[0072] The rotating shaft 12 is fixedly connected with a base 13, and the blower 1, the turbine 8, the protective casing 9, the vacuum pump 10, the isobaric combustion chamber 5 and the isothermal combustion chamber 11 are fixed with the base 13, and the base 13 can rotate together with the rotating shaft 12.

[0073] The air pipe 3 is provided with an air pipe inlet 31 and an air pipe outlet 32; the oil pipe 4 is provided with an oil pipe inlet 41 and an oil pipe outlet 42;

[0074] The air inlet of the blower 1 is connected to the external atmosphere, and the air outlet of the blower 1 passes through the rotary joint 2 through the pipe and then communicates with all air pipe inlets 31; the e...

Embodiment 3

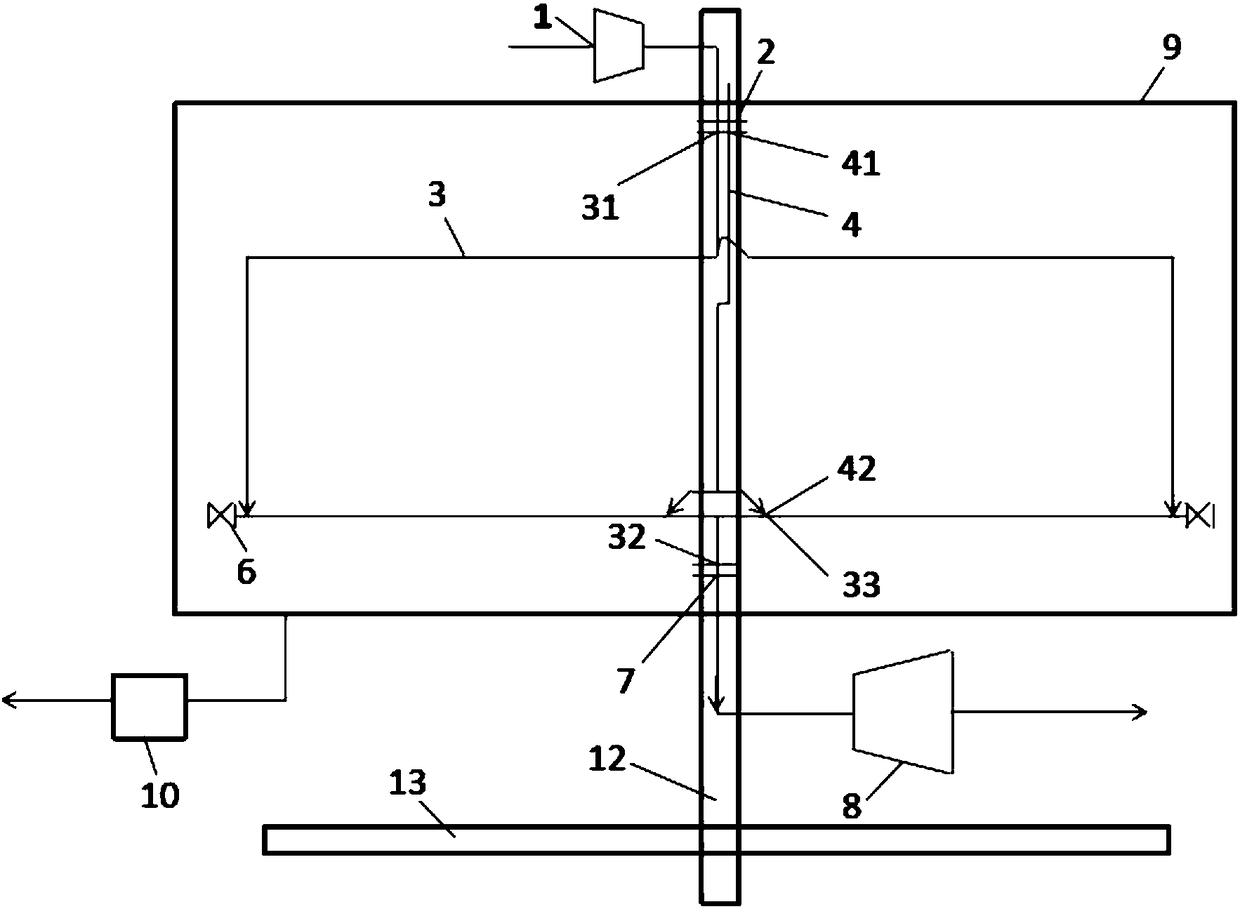

[0089] Embodiment 3, gas powered device, such as image 3 As shown, it includes a blower 1, a rotary joint, a turbine 8, an air pipe 3, an oil pipe 4, a rotating shaft 12, a protective shell 9 and a vacuum pump 10;

[0090] The rotating shaft 12 is fixedly connected with a base 13 , and the air blower 1 , the turbine 8 , the protective casing 9 and the vacuum pump 10 are fixed with the base 13 , and the base 13 can rotate together with the rotating shaft 12 .

[0091] Air pipe 3 is provided with air pipe inlet 31, air pipe oil injection port 33 and air pipe outlet 32; oil pipe 4 is provided with oil pipe inlet 41 and oil pipe oil outlet 42; the rotary joint includes rotary joint one 2 and rotary joint two 7 .

[0092] The air inlet of the blower 1 is connected to the external atmosphere, and the air outlet of the blower 1 passes through the rotary joint 2 through the pipe and then communicates with all air pipe inlets 31; the external oil supply pipeline passes through the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com