an electric water heater

An electric water heater and water inlet technology, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of manual operation confusion, unreliable control, and complicated action process for users, and achieve automatic control and Intelligent control, improve user experience, and save manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

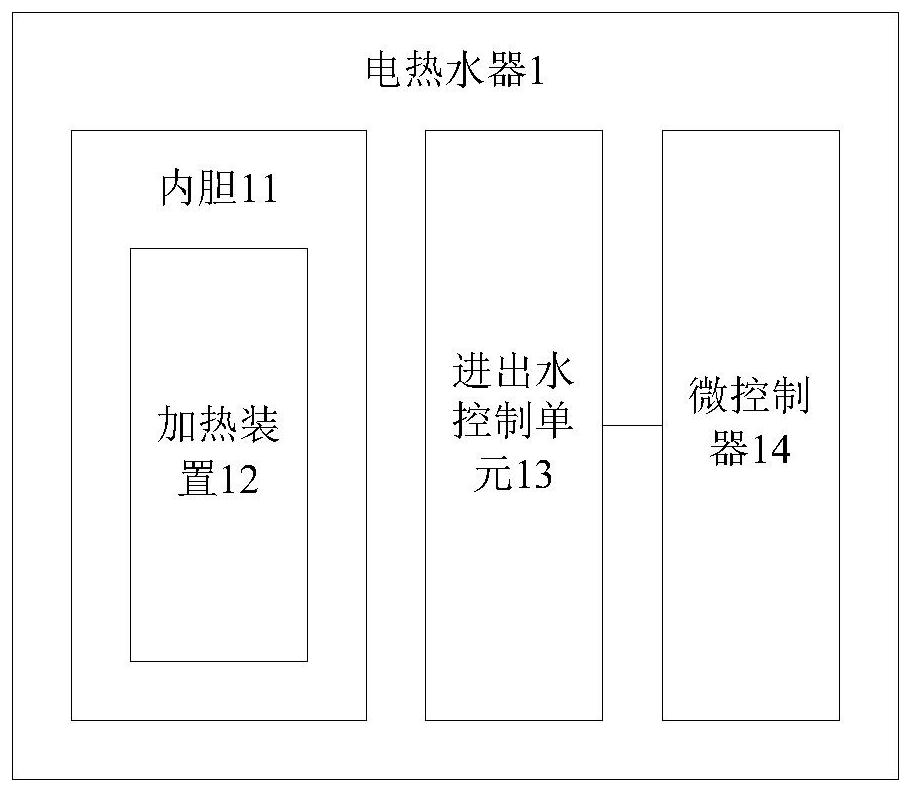

[0054] A kind of electric water heater 1, as figure 1 , figure 2 , image 3 As shown, the electric water heater 1 may include: an inner tank 11 and a heating device 12 disposed in the inner tank 11 , and also includes: a water inlet and outlet control unit 13 and a microcontroller 14 disposed outside the inner tank 11 ;

[0055] The microcontroller 14 is used to control the water in and out control unit 13 according to different heating modes, so as to realize variable volume heating; wherein the heating modes include: the whole tank heating mode and the half tank heating mode;

[0056] The water inlet and outlet control unit 13 is used to automatically control the water inlet and / or outlet of the inner tank 11 according to the control instructions of the microcontroller 14 .

[0057] In the embodiment of the present invention, the heating device 12 mainly realizes the heating function of the electric water heater. For example), the reliable operation of the variable capac...

Embodiment 2

[0059] This embodiment introduces the composition and structure of the water inflow and outflow control unit 13 in detail on the basis of the first embodiment.

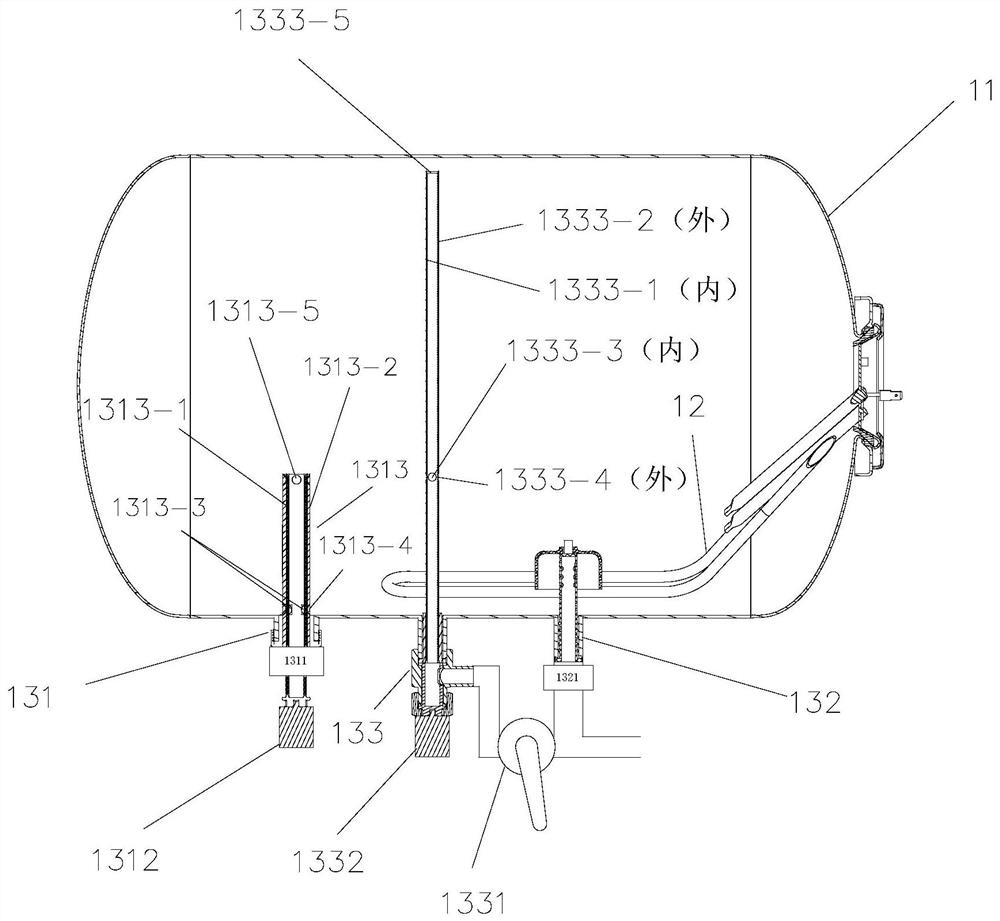

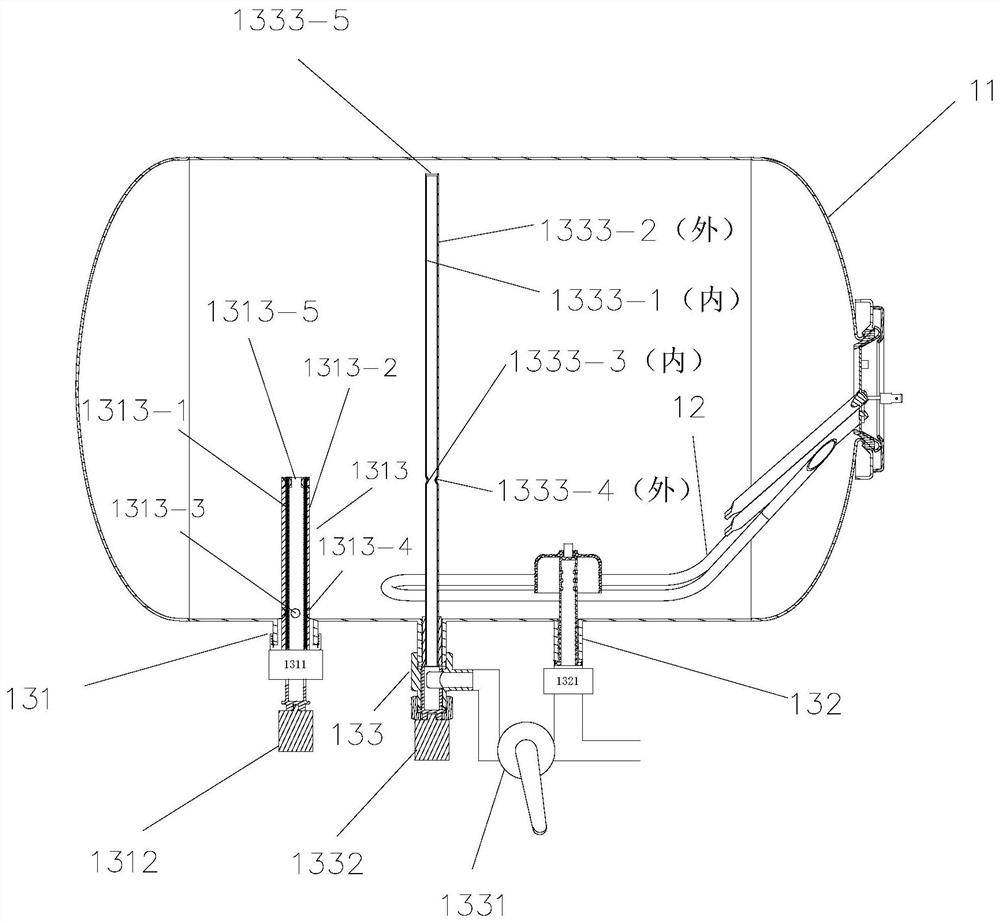

[0060] Optionally, as in figure 2 , image 3 As shown, the water inlet and outlet control unit 13 may include: a sewage discharge assembly 131, a water inlet assembly 132 and a water outlet assembly 133;

[0061] The sewage discharge assembly 131 is used to discharge the sewage in the inner tank 11, and is used to discharge the excess water in the inner tank 11 when the electric water heater 1 is converted from the whole tank heating mode to the half tank heating mode, and to control the heating water level of the half tank ;

[0062] The water inlet assembly 132 is used to control the on-off of the water inlet. The water inlet assembly 132 may include a second control switch 1321 and a water inlet pipe; the second control switch 1321 is arranged on the water inlet pipe for controlling the opening of the water inle...

Embodiment 3

[0081] Such as Figure 5 As shown, this embodiment provides different control methods of the electric water heater for the water in and out control unit 13 in different heating modes on the basis of the second embodiment.

[0082] In the embodiment of the present invention, before heating, the system first initializes each hardware interface and drive module, and judges whether the variable volume heating function is activated; when the variable volume heating is not activated, the system works in the working state of the whole tank heating, The water inlet component 132 of the system is turned on, the sewage component 131 is turned off, the heating function is started, and the normal water heater heating operation is performed; the control method in the whole tank heating mode will be introduced in detail below:

[0083] Optionally, when the heating mode is the whole tank heating mode, the water inlet and outlet control unit 13 automatically controls the water inlet and outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com