Full single-mode fiber F-P sensor and manufacturing method thereof

A single-mode fiber, F-P technology, applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems such as the quality of the F-P cavity being easily affected by the processing technology, the high production cost of the fiber F-P interferometer, and the limitation of the fiber F-P interferometer, etc. Achieve the effect of reducing cross-sensitivity problems, compact structure, and small temperature influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The objects and functions of the present invention and methods for achieving the objects and functions will be clarified by referring to the exemplary embodiments. However, the present invention is not limited to the exemplary embodiments disclosed below; it can be implemented in various forms. The essence of the description is only to help those skilled in the relevant art comprehensively understand the specific details of the present invention.

[0042] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings, the same reference numerals represent the same or similar components, or the same or similar steps.

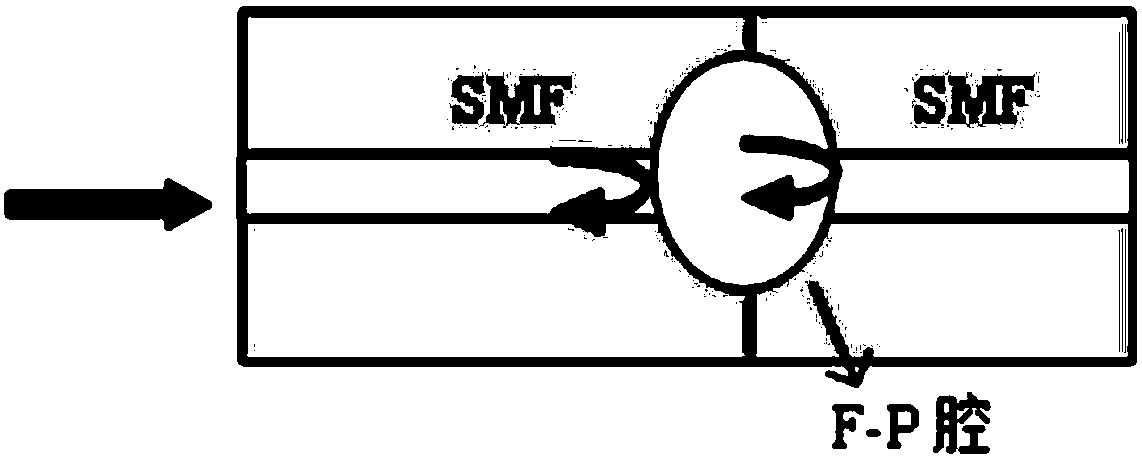

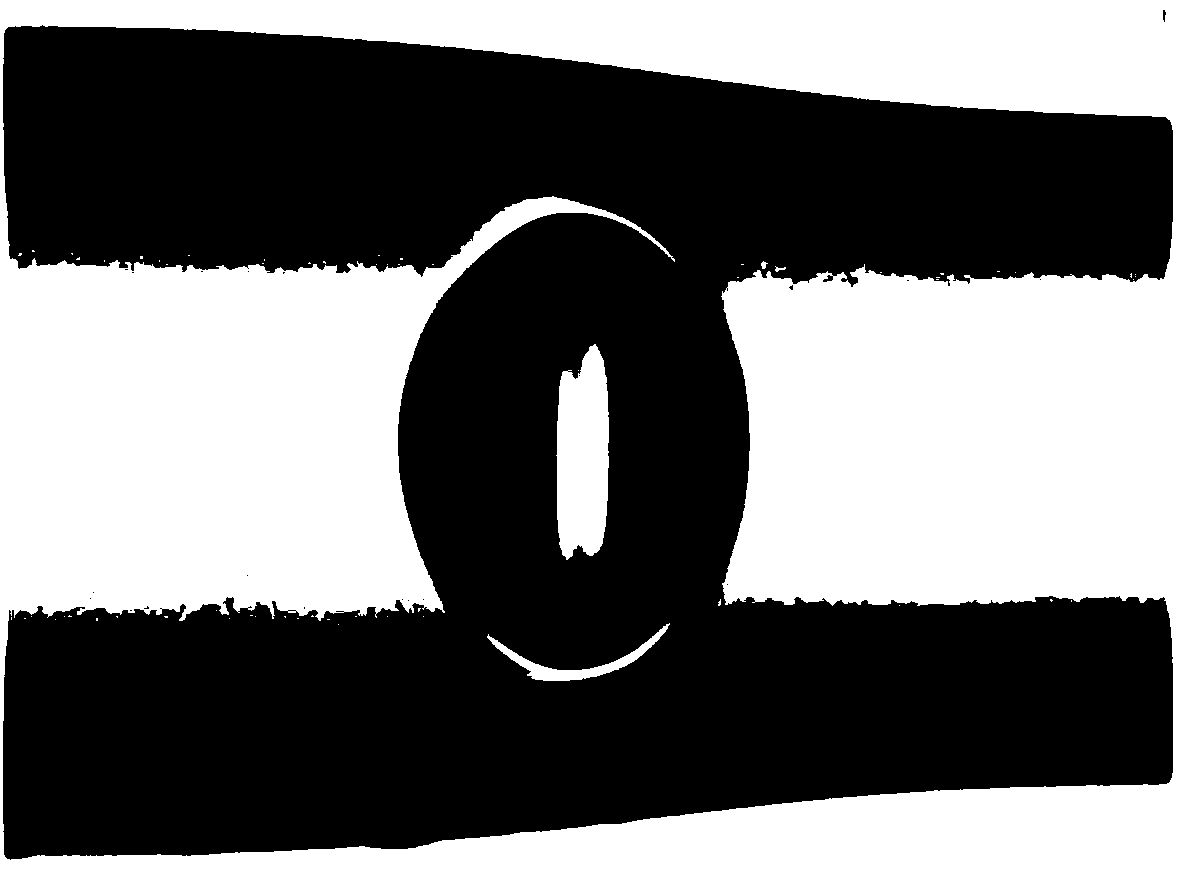

[0043] see Figure 1-Figure 3 , the present invention provides an all-single-mode optical fiber F-P sensor, comprising: a first single-mode optical fiber and a second single-mode optical fiber, the first single-mode optical fiber is fused with the second single-mode optical fiber, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com