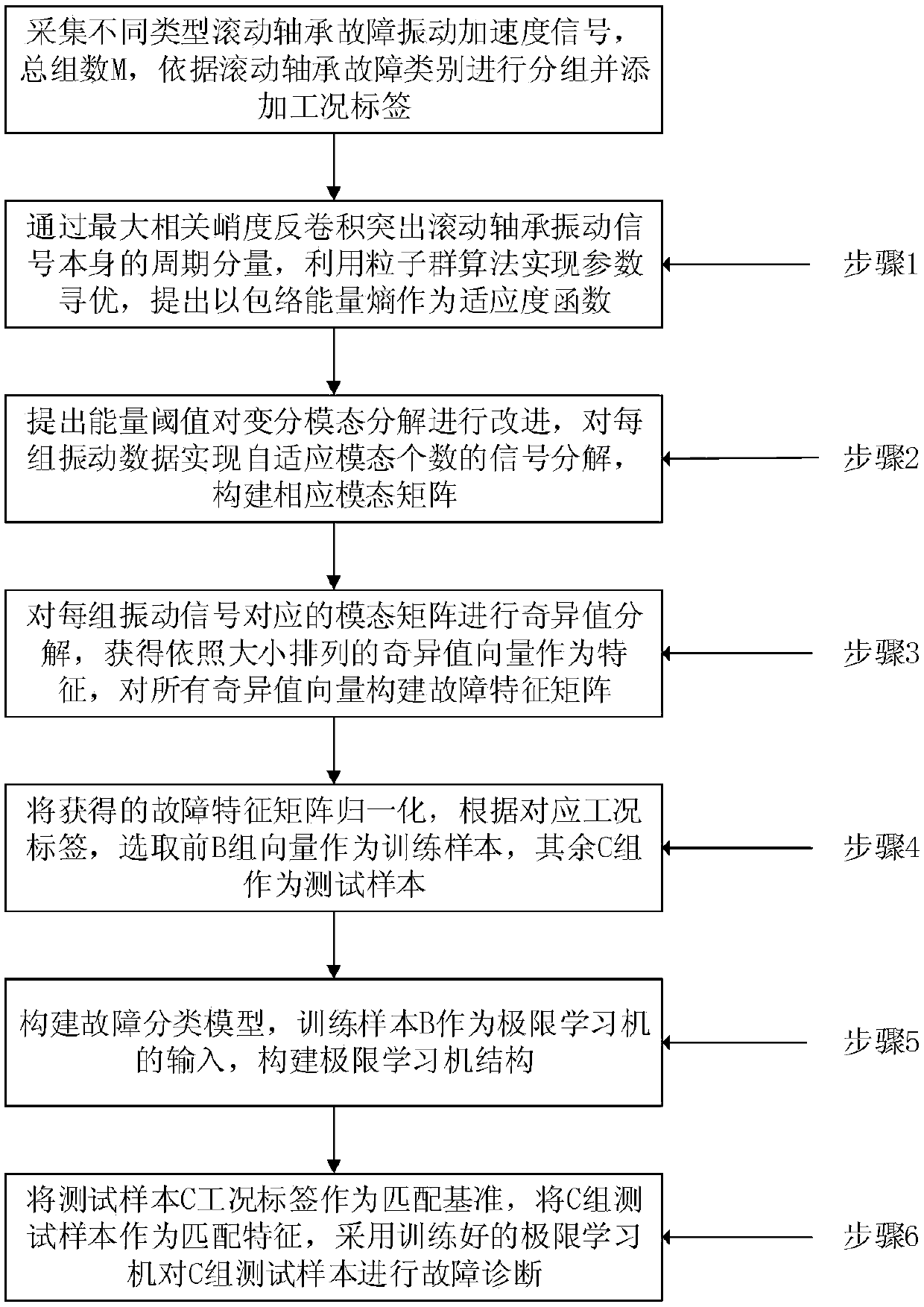

Rolling bearing fault diagnosis method based on improved variational model decomposition and extreme learning machine

A variational modal decomposition, extreme learning machine technology, applied in mechanical bearing testing, computational models, biological models, etc., can solve complex recursion, modal aliasing, lack of physical meaning and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

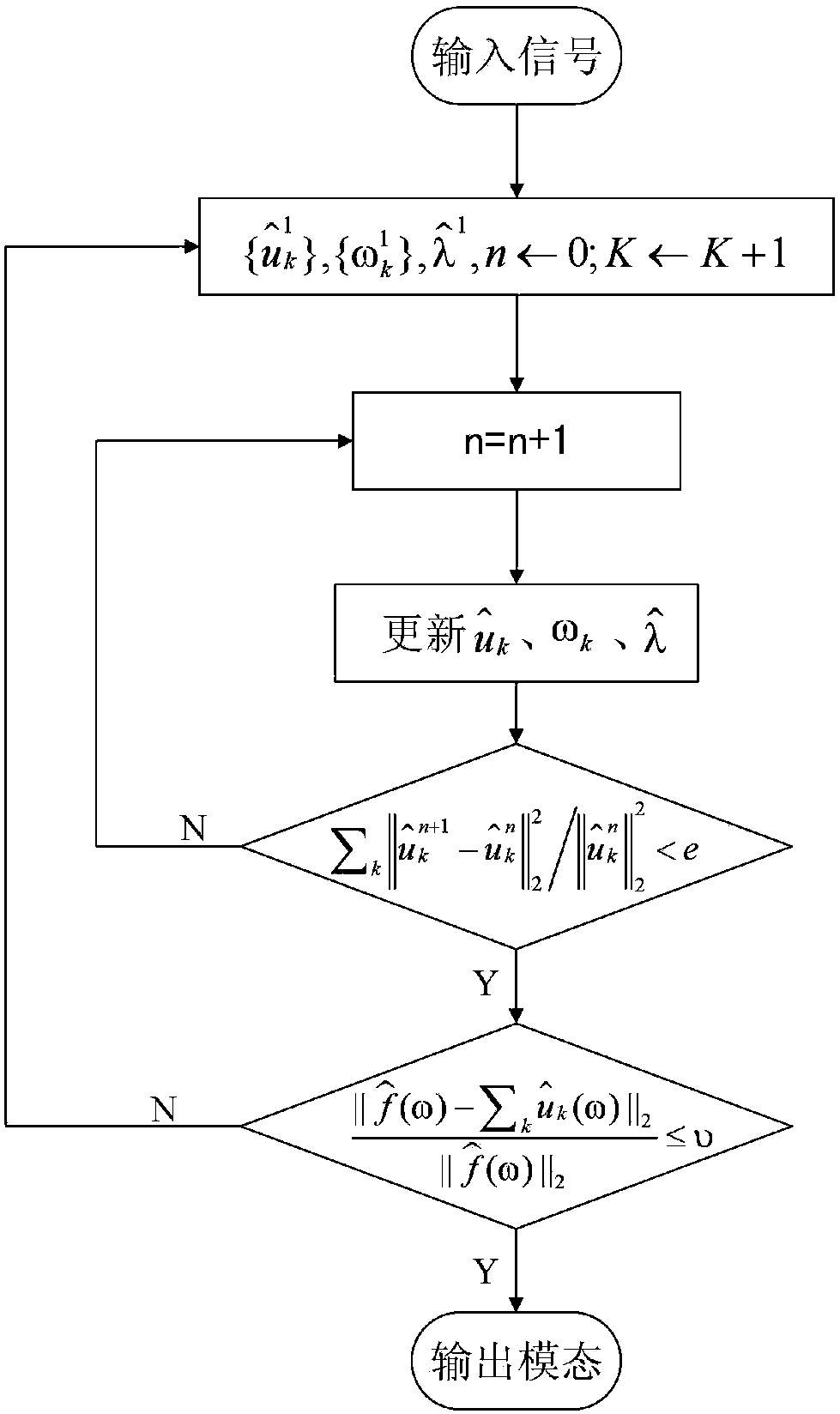

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited by the specific embodiments.

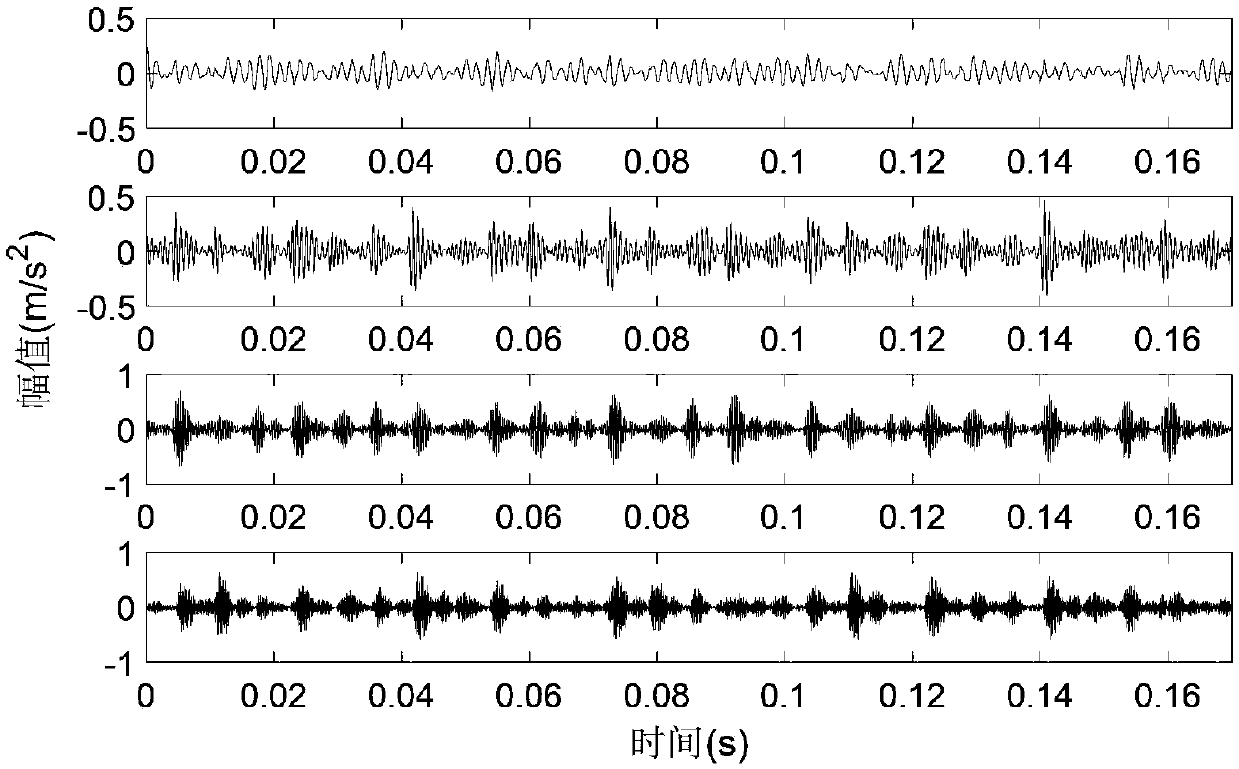

[0050] The example of the present invention uses the rolling bearing fault signal as the experimental basis for analysis and processing. The bearing model is 6205-2RS JEM SKF, and the number of rolling elements is 9. A single point fault with a diameter of 0.1778mm and a depth of 0.2794mm is artificially introduced into the bearing through EDM technology. The vibration acceleration signals of rolling bearings under different single fault types are collected by acceleration vibration sensors installed in different parts of the rolling bearings. The sampling frequency is 12kHz and the speed is 1797rpm. The data contains 4 types of rolling bearing fault data, including normal data and inner ring fault data. , Outer ring fault data, rolling body fault data, each type of fault...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com