High-bearing universal joint, mechanical arm joint and flexible mechanical arm

A universal joint, high load-bearing technology, applied in the field of robots, can solve the problems of small load-carrying capacity, under-actuated, complex structural design, etc., and achieve the effect of improving load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

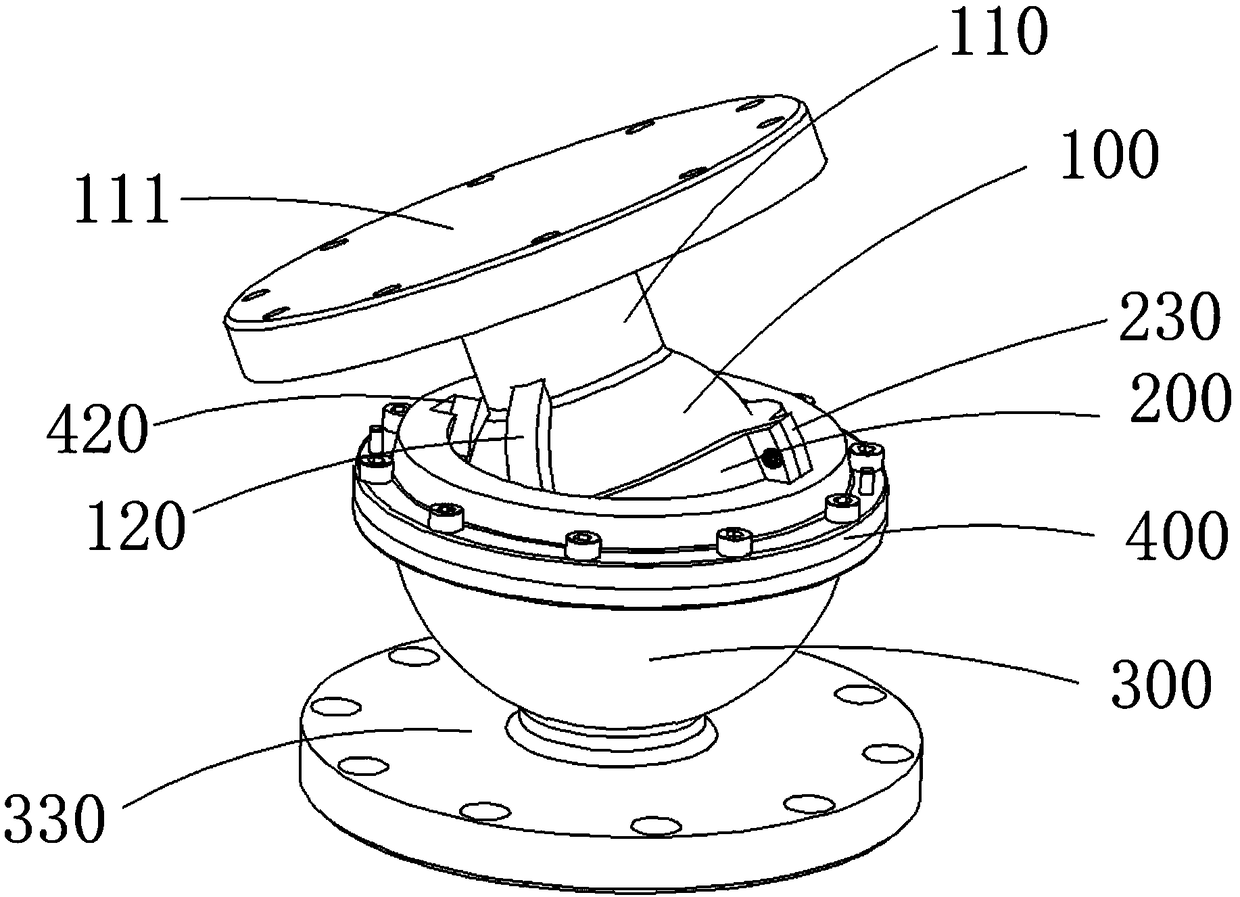

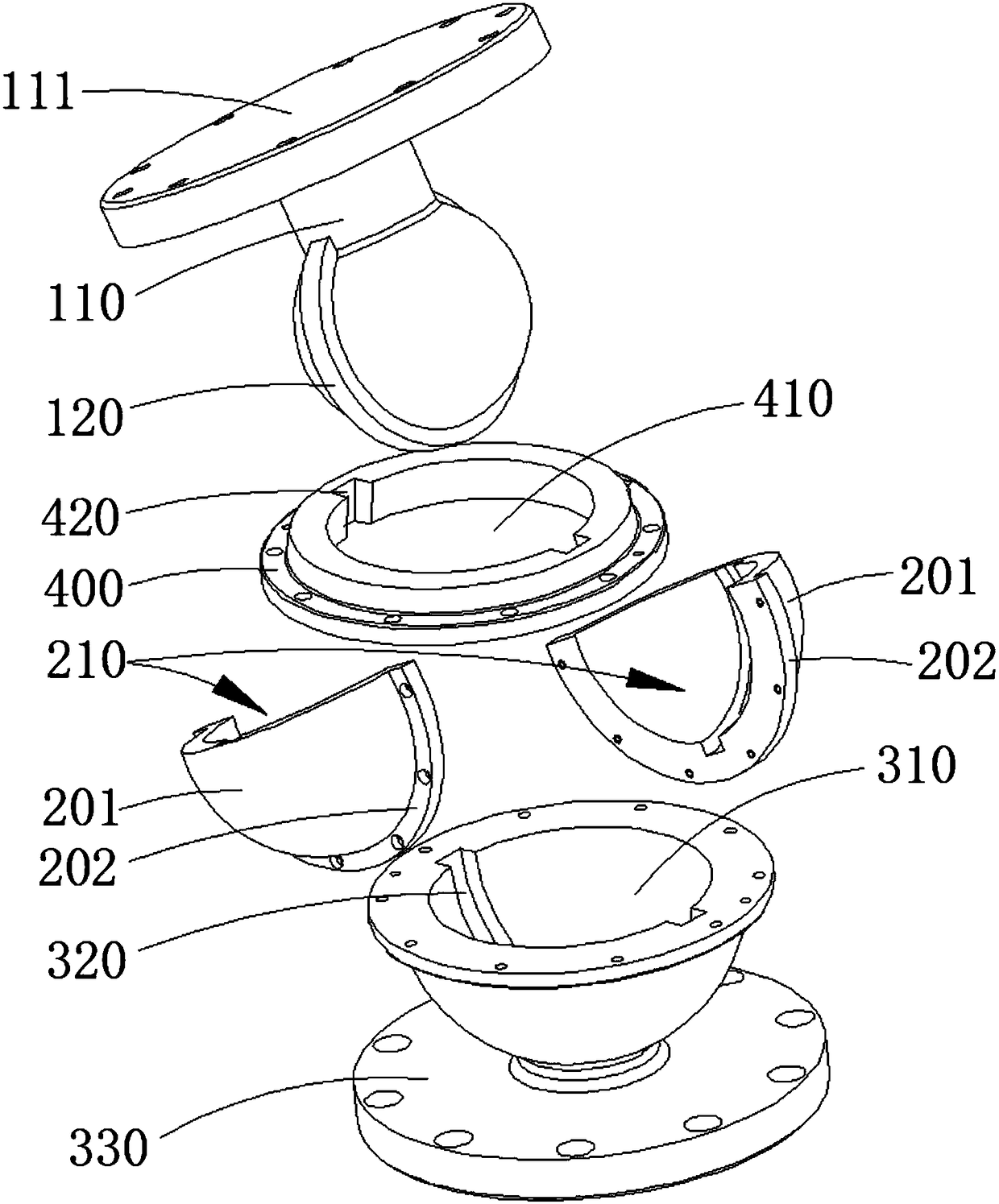

[0030] figure 1 It is a schematic diagram of the overall structure of an embodiment of the high-load universal joint of the present invention, figure 2 for figure 1 The disassembled schematic diagram of the embodiment shown, while referring to figure 1 , 2 , a high-load universal joint, including a first sliding ball 100 , a second sliding ball 200 , a ball seat 300 and a gland 400 .

[0031] The first sliding ball 100 is a solid spherical member, on which a connecting portion 110 is fixedly arranged for connecting with an external member. The second sliding ball 200 includes a first cavity 210 whose inner surface is a spherical surface. The first sliding ball 100 is rotatably arranged in the first cavity 210 and fits with the inner surface of the first cavity 210. The first sliding ball 100 Can slide along the inner surface of the first cavity 210, compared with the cross joint in the prior art, the spherical contact provides a larger contact area for the movement betwee...

Embodiment 2

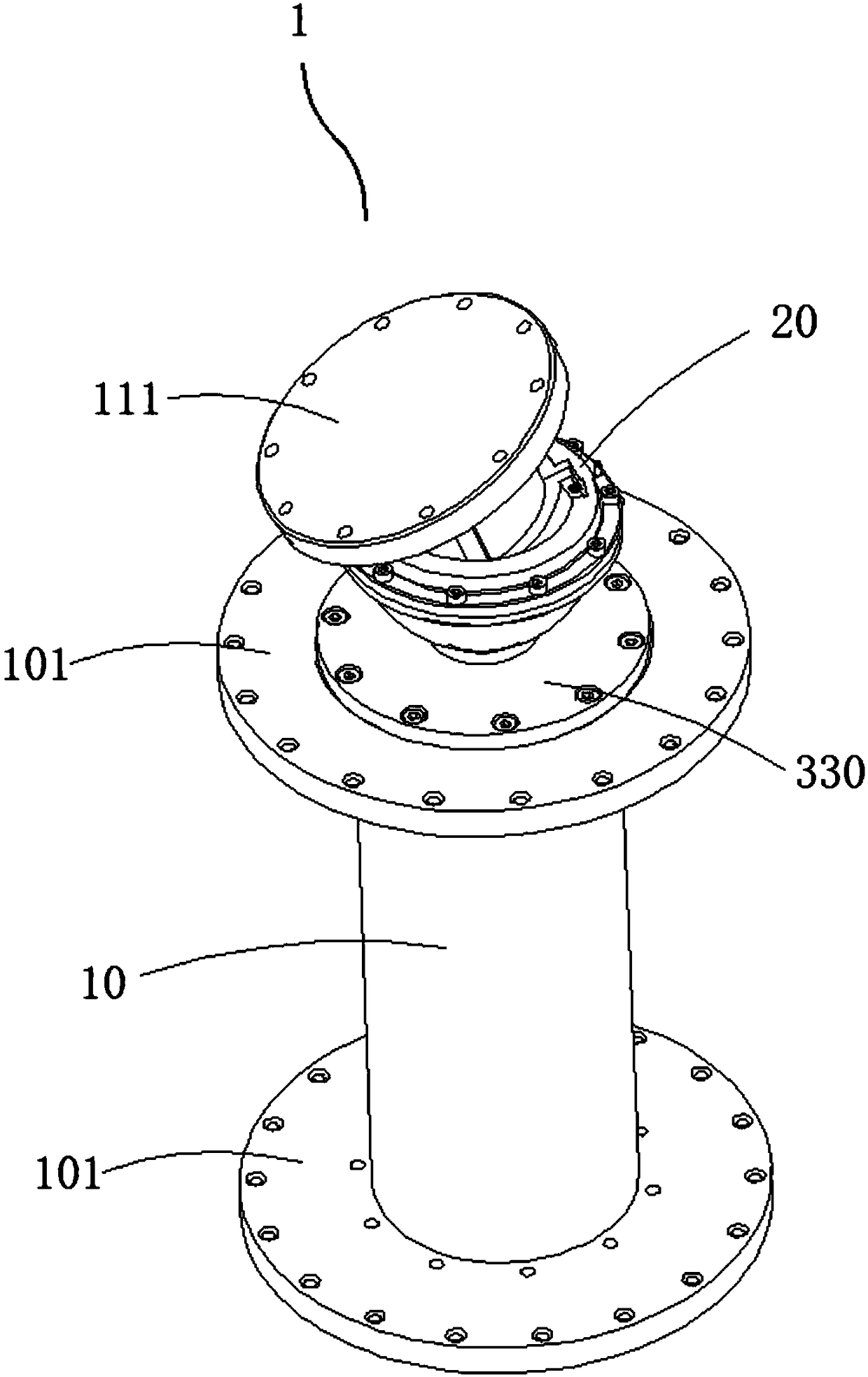

[0042] image 3 It is a structural schematic diagram of an embodiment of the mechanical arm joint of the present invention, refer to image 3 In this embodiment, the mechanical arm joint 1 includes a joint body 10 and a universal joint 20. The universal joint 20 in this embodiment is the high-load universal joint described in the first embodiment above, which is beneficial to improve the bearing capacity of the mechanical arm joint , wherein the connecting body includes the first connecting disk 111 , the ball seat includes the second connecting disk 330 , and the condyle body 10 is fixedly connected to the first connecting disk 111 or the second connecting disk 330 . The first connecting plate 111 and the second connecting plate 330 have the same structure, which can shorten the machining cycle and reduce the cost, and can be installed with any one of them when installing the condyle body 10 without considering the installation sequence, which is conducive to improving assemb...

Embodiment 3

[0044] Figure 4 It is a structural schematic diagram of an embodiment of the flexible robotic arm of the present invention, refer to Figure 4 , the flexible mechanical arm of this embodiment includes a driving device and several mechanical arm joints 1, the mechanical arm joints 1 are sequentially connected to form a long strip, the driving device includes several driving ropes 2, and the end of the driving rope 2 is connected to the installation end of the mechanical arm joints. 101 are fixedly connected, and the mounting end 101 is also provided with a perforation 102 for passing the driving rope 2 , and each mounting end 101 is fixedly connected with three driving ropes 2 . The joints 1 of the mechanical arm are respectively driven to move around the universal joint 20 through the driving rope 2, so as to realize the bending action of the flexible mechanical arm as a whole. During specific implementation, the joints of the robotic arm are the joints of the robotic arm de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com