Printer forming cylinder and using method thereof

A technology for forming cylinders and printers, used in manufacturing auxiliary devices, additive processing, etc., can solve the problems of powder waste, powder mixing pollution, and inability to classify and recycle powder, and achieve the effect of avoiding powder waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

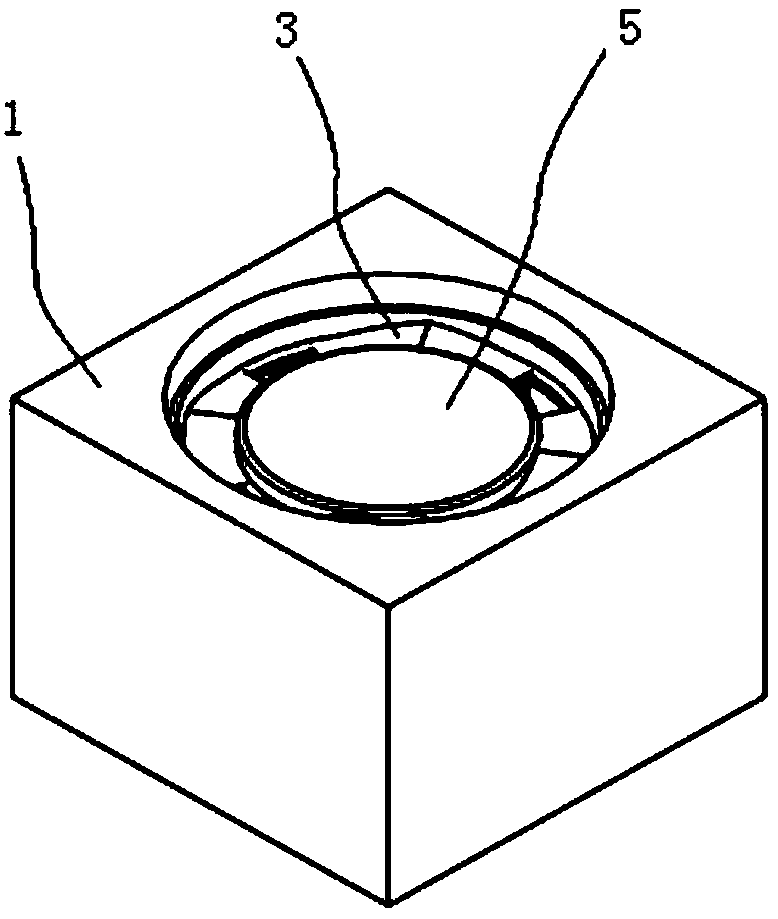

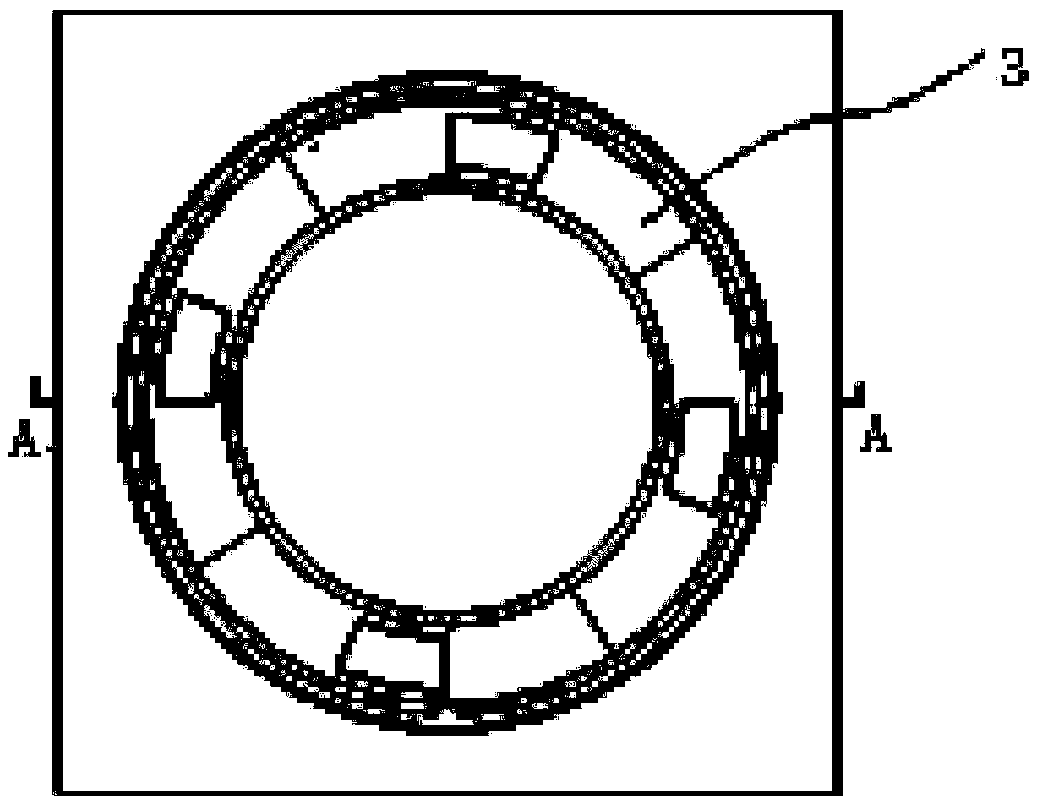

[0047] Such as Figure 1-6 As shown, the present invention discloses a printer forming cylinder. Among them, the printer forming cylinder includes a cylinder body 1, a hollow piston 2, a powder leakage ring 3, a powder recovery box 4 and a central base plate 5.

[0048] The hollow piston 2 is a hollow barrel structure, the hollow piston 2 is installed in the cylinder 1, and the hollow piston 2 and the cylinder 1 are sealed and slidably connected; to prevent the protective atmosphere from leaking from the gap between the hollow piston 2 and the cylinder 1 When the powder is recovered, the protective atmosphere in the molding chamber is kept stable.

[0049] The powder leakage ring 3 is a ring structure, which is installed in the hollow piston 2. The powder leakage ring 3 can rotate at a first preset angle each time, and the powder leakage ring 3 is evenly distributed with second preset holes 101, the powder leakage ring A second preset slide 102 is evenly distributed on 3, and the...

Embodiment 2

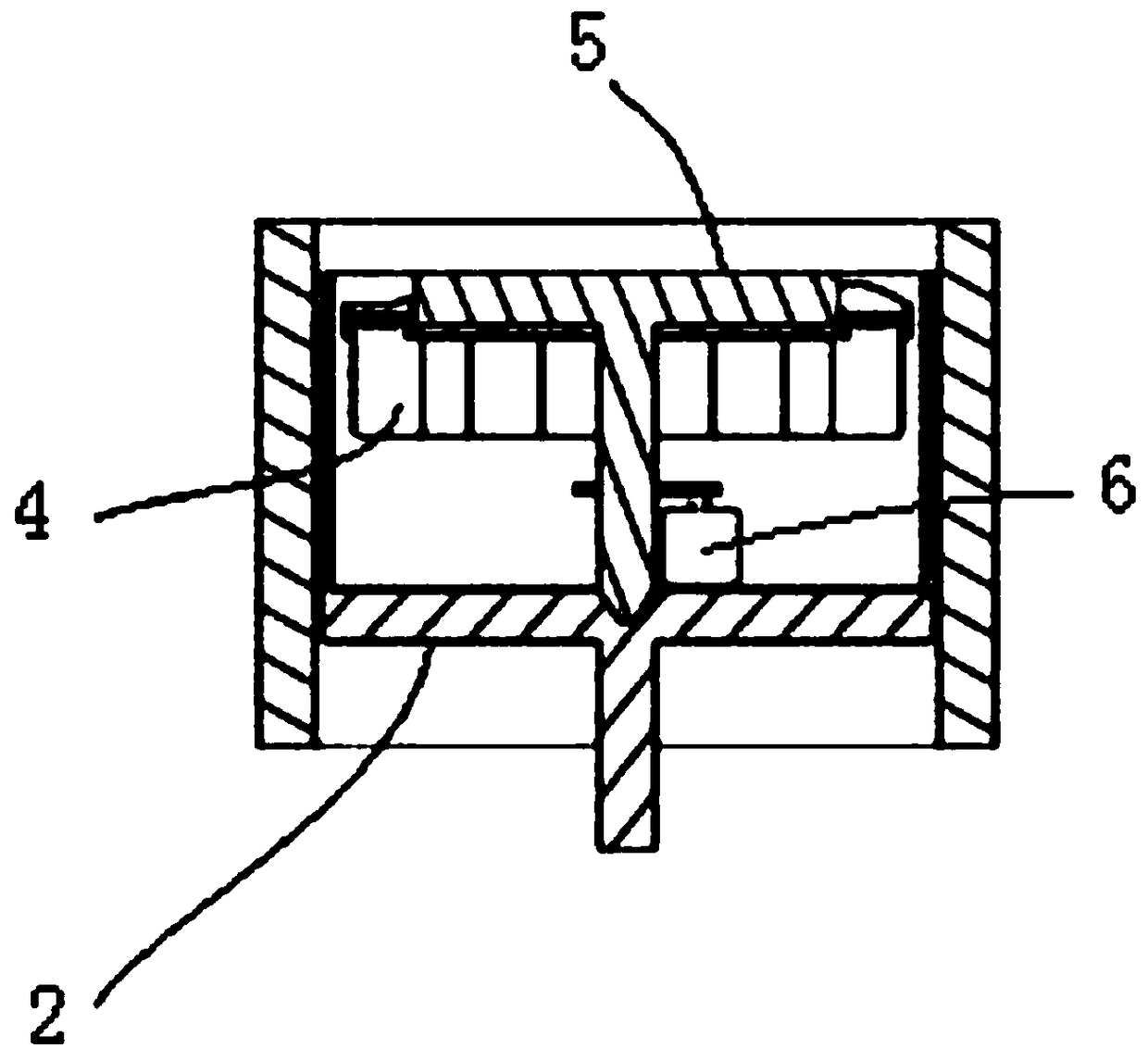

[0055] In the second embodiment provided by the present invention, the printer forming cylinder in this embodiment has a similar structure to the printer forming cylinder in the first embodiment, and the similarities are not repeated here, and only the differences are introduced.

[0056] In this embodiment, it is specifically disclosed that the printer molding cylinder further includes a driving device 6 installed in the hollow piston 2 and the driving device 6 can drive the central substrate 5 to rotate. The driving device 6 may be a servo motor or other motors with a control system. In this embodiment, the driving device 6 is a servo motor as an example. The hollow piston 2 is controlled by the servo motor. After the laser finishes sintering a layer of powder, the hollow piston 2 is lowered by a predetermined layer thickness. The central base plate 5 is controlled by a servo motor and can rotate a fixed number of turns around the central axis at a certain speed, and the speed ...

Embodiment 3

[0065] Such as Figure 7 As shown, the present invention discloses a method for using a printer forming cylinder. Using the printer forming cylinder in any one of the above embodiments includes the following steps:

[0066] Step S1: Reset the powder leakage ring 3 so that the opening of the powder recovery box 4 to be filled with powder faces the hole 101.

[0067] The powder leakage ring 3 can rotate relative to the hollow piston 2 so that the opening of the powder recovery box 4 to be filled with powder is directly facing the hole 101 of the powder leakage ring 3.

[0068] Step S2: Lower the hollow piston 2 by a distance of one layer thickness.

[0069] The hollow piston 2 is controlled by a servo motor. When the laser finishes sintering a layer of powder, the hollow piston 2 is lowered by a preset distance of a layer thickness, and the distance of a layer thickness can be set according to the actual needs of the powder.

[0070] Step S3: Lay powder on the central substrate 5 and scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com