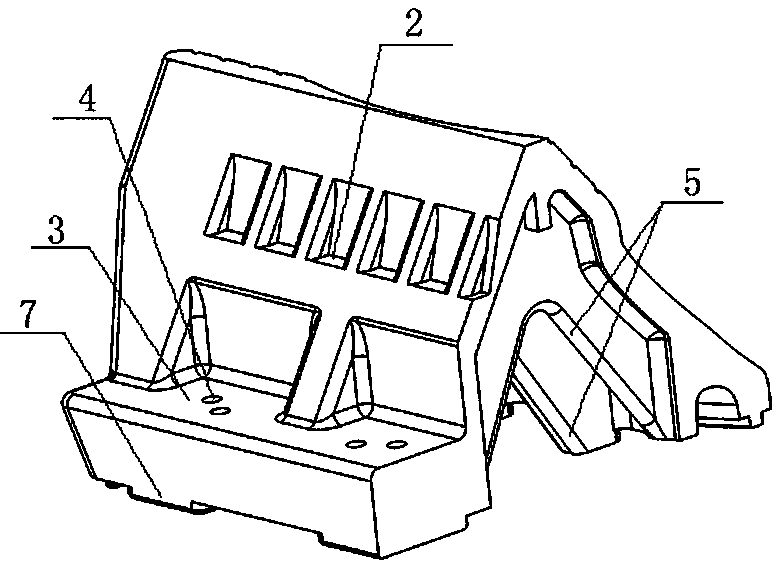

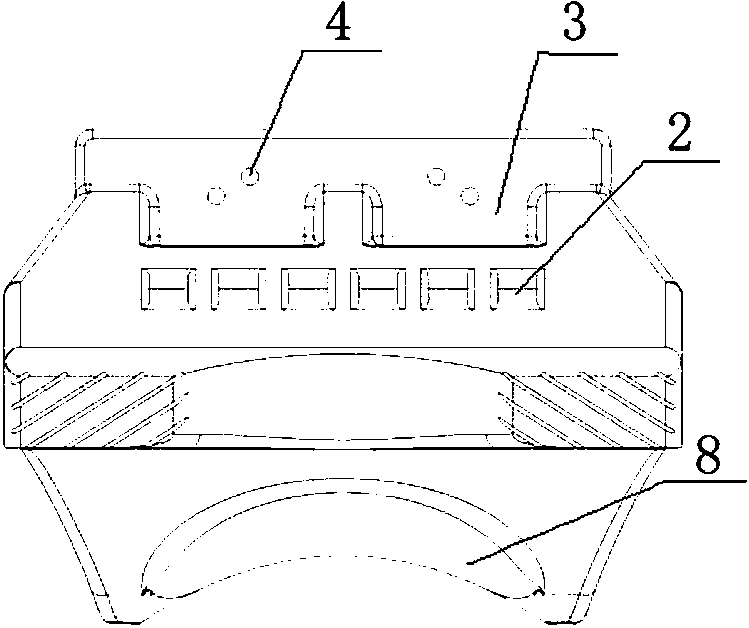

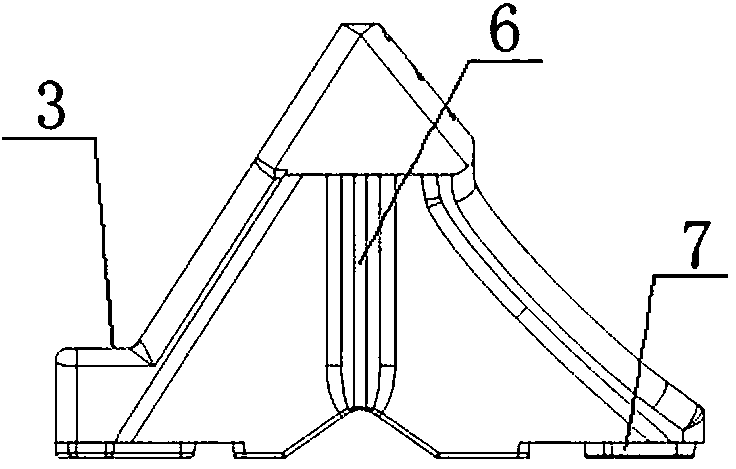

Wheel stopper

A wheel block and resin technology, applied in the field of wheel blocks for shielding wheeled goods, can solve the problems of unscientific force analysis, large scrap loss, long manufacturing cycle, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] Take 100 parts of HDPE resin, 20 parts of LDPE resin, 50 parts of red mud, 1 part of HSt stearic acid, 1 part of KR-212 coupling agent, 0.2 part of 1010 primary antioxidant, 0.3 part of DLTP secondary antioxidant, carbon black 0.15 parts, 25 parts of decabromodiphenyl ether, 8 parts of dilead trioxide, stir and mix evenly.

example 2

[0053] Take 100 parts of HDPE resin, 18 parts of POE resin, 60 parts of red mud, 1 part of HSt stearic acid, 1 part of KR-212 coupling agent, 0.2 part of 1010 primary antioxidant, 0.3 part of DLTP secondary antioxidant, carbon black 0.15 parts, 25 parts of decabromodiphenyl ether, 8 parts of dilead trioxide, stir and mix evenly.

[0054] Send the ingredients into the extruder, extrude after heating and smelting, fill into the mold and press to form, and release the mold after solidification to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com