A kind of titanium matrix composite material and preparation method thereof

A technology of titanium-based composite materials and composite materials, applied in the field of titanium-based composite materials and their preparation, can solve problems affecting TiN formation, short hot-pressing sintering time, grain growth, etc., to increase ball milling speed and improve mechanical properties , the effect of eliminating oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

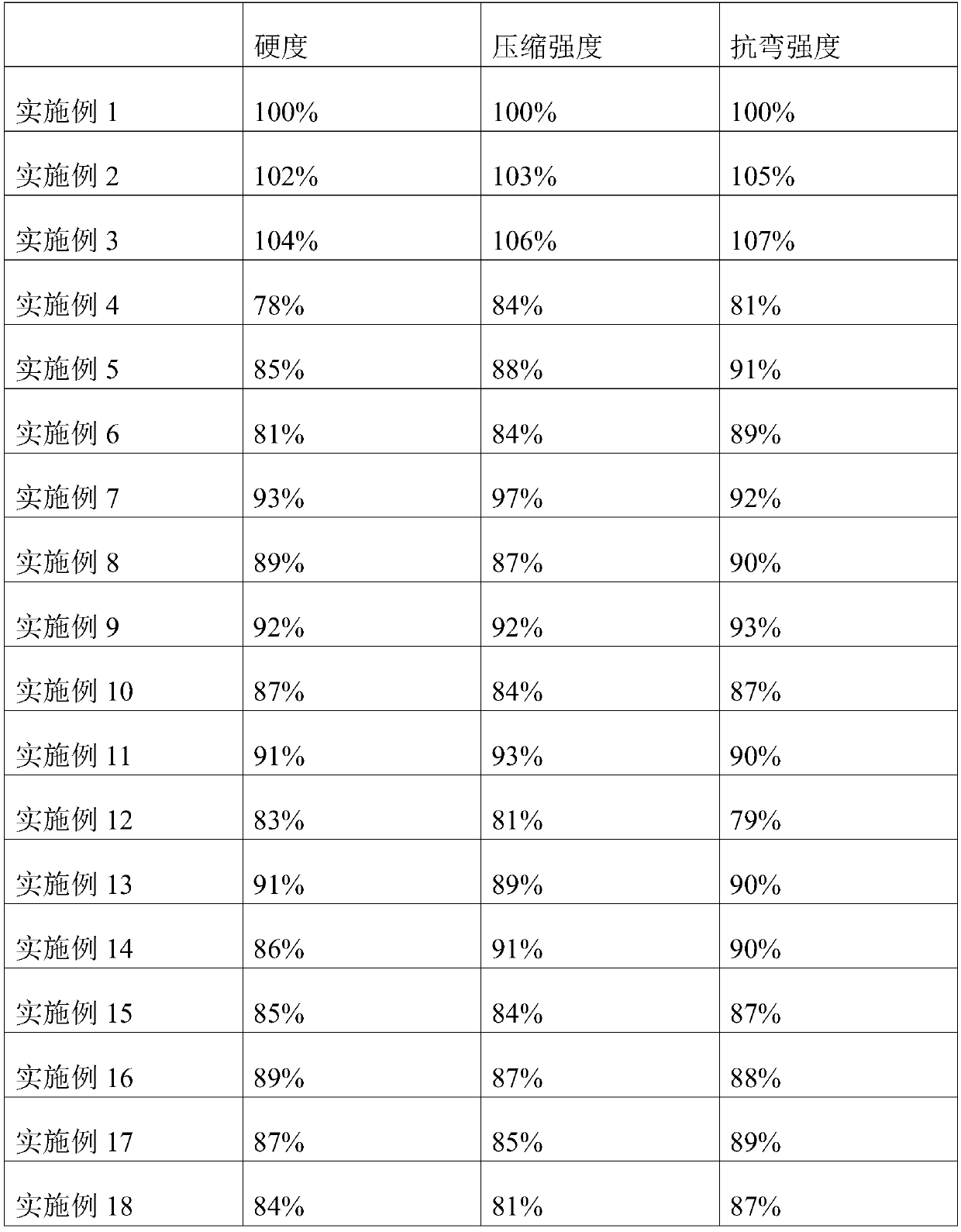

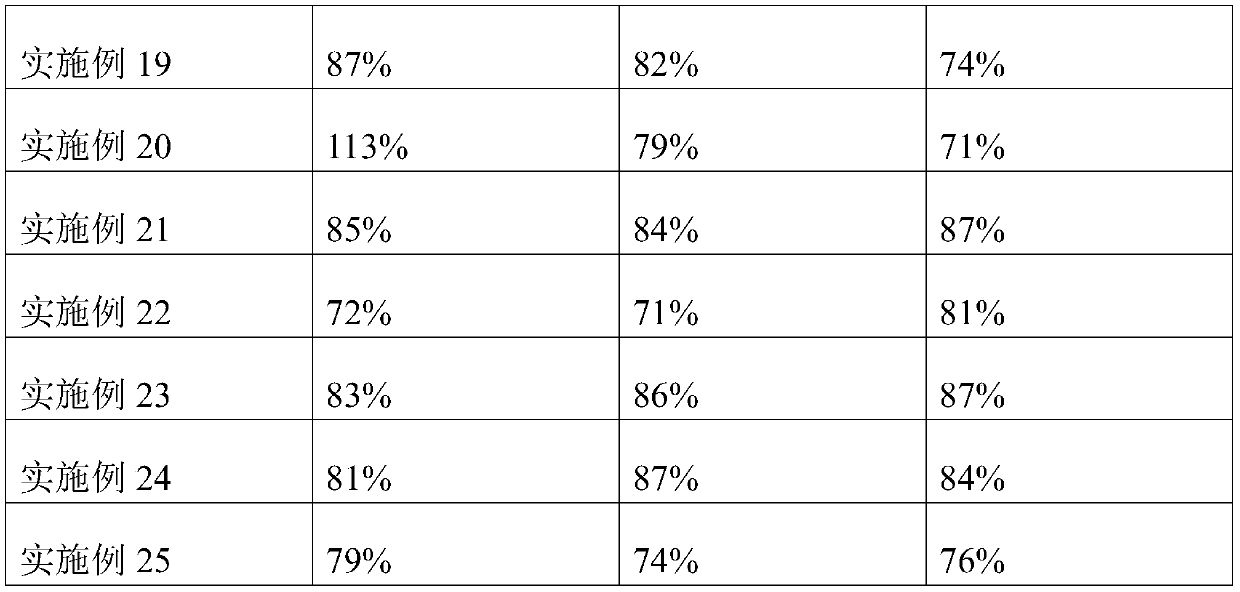

Examples

Embodiment 1

[0019] The titanium-based composite material is prepared as follows: Ti powder and SiC powder are provided; Ti powder and SiC powder are mixed to obtain a first mixed powder; the first mixed powder is subjected to first ball milling under a nitrogen atmosphere to obtain a second mixed powder, Wherein, the process of the first ball milling is as follows: the rotating speed is 500r / min, and the time is 1h; the second mixed powder is subjected to the first heat treatment to obtain the third mixed powder; the third mixed powder is subjected to the second ball milling under nitrogen atmosphere to obtain The fourth mixed powder, wherein the second ball milling process is: the rotating speed is 500r / min, and the time is 3h; the fourth mixed powder is subjected to the second heat treatment to obtain the fifth mixed powder; and the fifth mixed powder is hot-pressed and sintered . The first heat treatment is carried out under a hydrogen atmosphere, and the process of the first heat trea...

Embodiment 2

[0021] The titanium-based composite material is prepared as follows: Ti powder and SiC powder are provided; Ti powder and SiC powder are mixed to obtain a first mixed powder; the first mixed powder is subjected to first ball milling under a nitrogen atmosphere to obtain a second mixed powder, Among them, the process of the first ball milling is as follows: the rotating speed is 600r / min, and the time is 2h; the second mixed powder is subjected to the first heat treatment to obtain the third mixed powder; the third mixed powder is subjected to the second ball milling under nitrogen atmosphere to obtain The fourth mixed powder, wherein the second ball milling process is as follows: the rotating speed is 600r / min, and the time is 4h; the fourth mixed powder is subjected to the second heat treatment to obtain the fifth mixed powder; and the fifth mixed powder is hot-pressed and sintered . The first heat treatment is carried out under a hydrogen atmosphere, and the process of the f...

Embodiment 3

[0023] The titanium-based composite material is prepared as follows: Ti powder and SiC powder are provided; Ti powder and SiC powder are mixed to obtain a first mixed powder; the first mixed powder is subjected to first ball milling under a nitrogen atmosphere to obtain a second mixed powder, Wherein, the process of the first ball mill is as follows: the rotating speed is 500-600r / min, and the time is 1-2h; the second mixed powder is subjected to the first heat treatment to obtain the third mixed powder; the third mixed powder is subjected to the second mixed powder under nitrogen atmosphere. Two ball milling to obtain the fourth mixed powder, wherein the process of the second ball mill is: the rotating speed is 500-600r / min, and the time is 3-4h; the fourth mixed powder is subjected to the second heat treatment to obtain the fifth mixed powder; and The fifth mixed powder is subjected to hot pressing and sintering. The first heat treatment is carried out under a hydrogen atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com