Post tensioned pre-stressed hollow type pier column structure and construction method

A post-tensioning prestressed, hollow-type technology, applied to bridges, bridge parts, bridge materials, etc., can solve the problems of long working time at high altitude, high risk, and large material amortization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

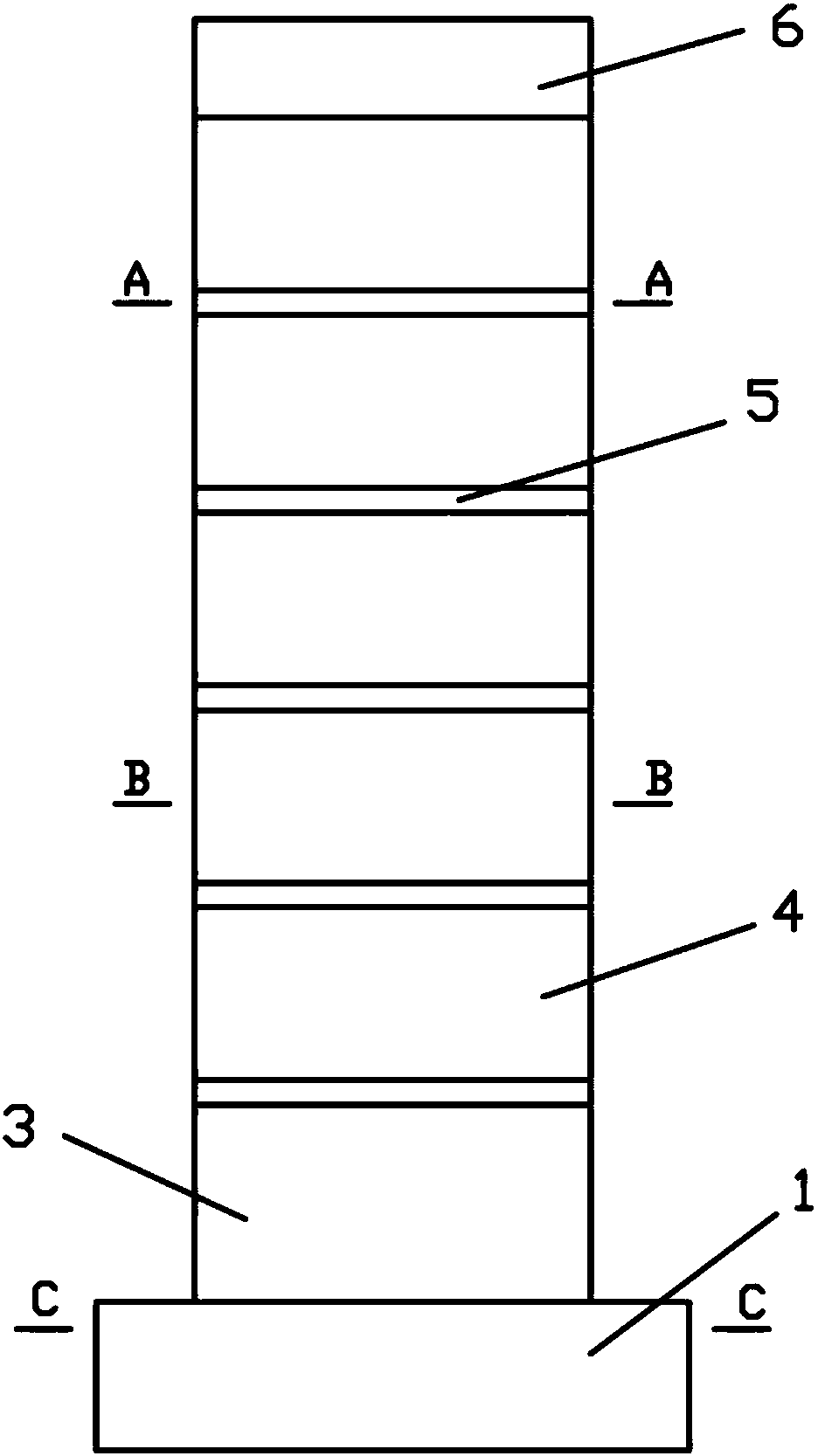

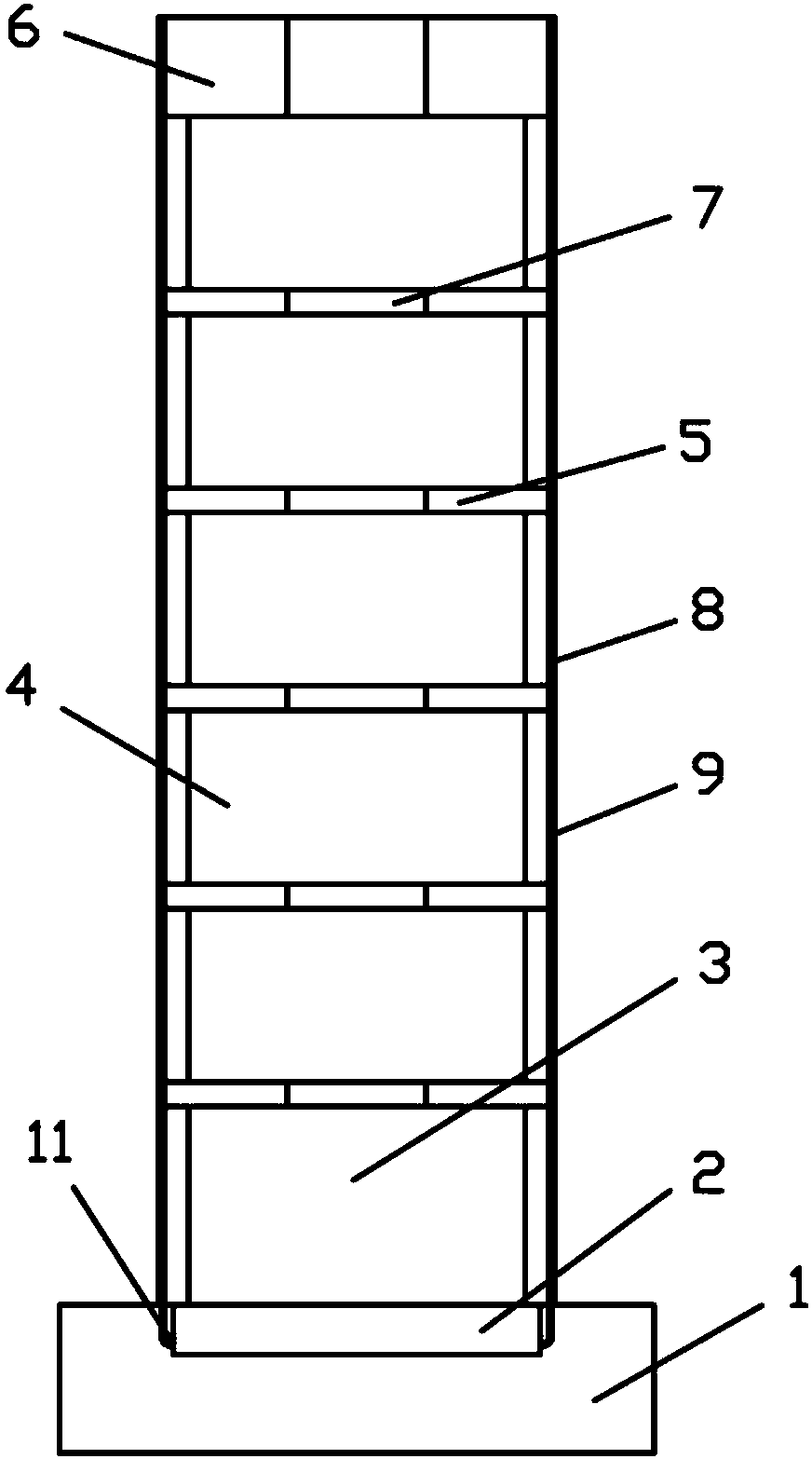

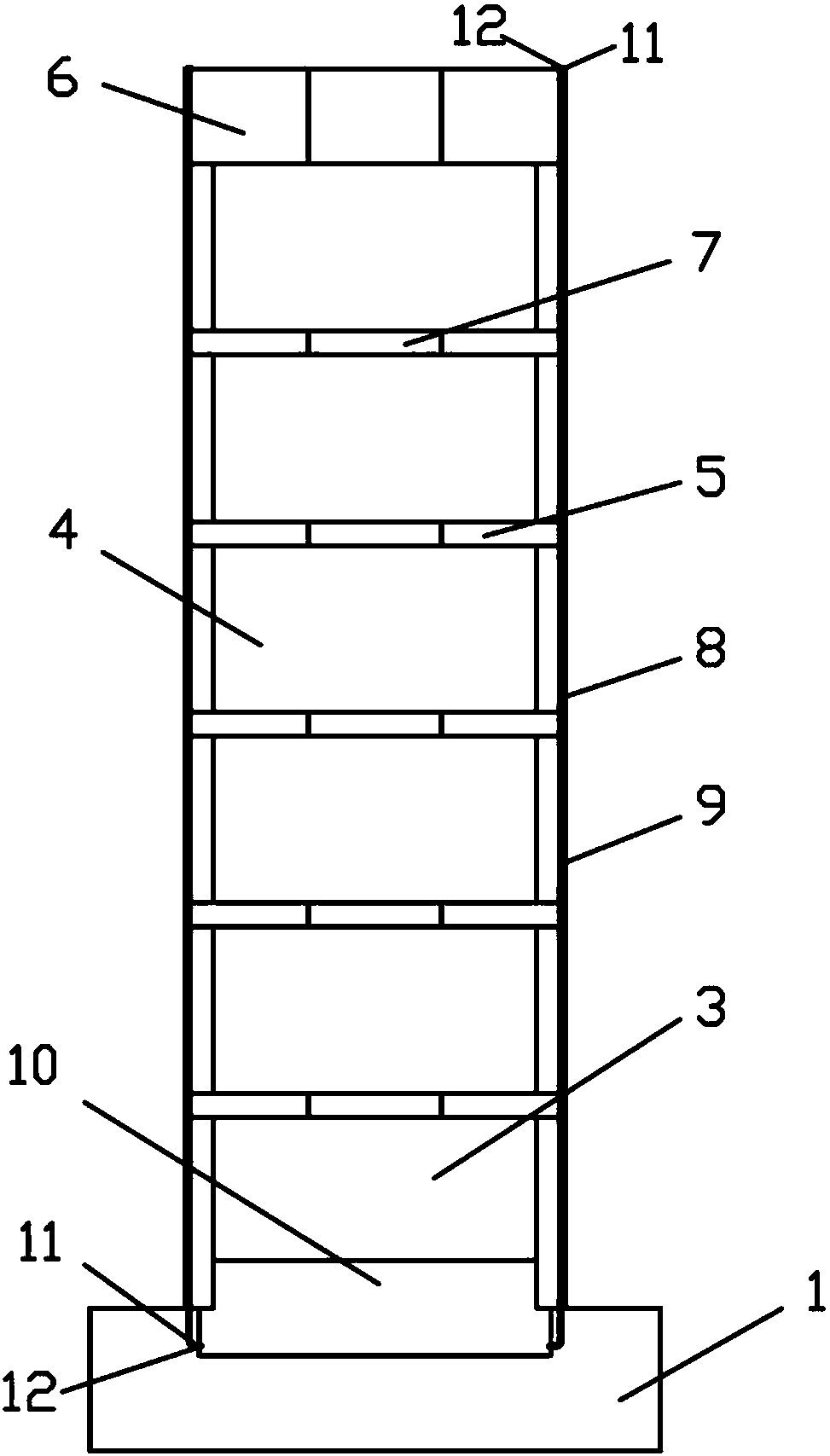

[0025] like Figure 1 to Figure 6 As shown, a post-tensioned prestressed prefabricated hollow pier column structure according to the present invention includes caps 1, pier columns, prestressed steel bars 9, pipe grouting materials, concrete wet joints 10, viscose, anchor plates 11 and anchors Tool 12, the pier column includes a bottom segment 3, a standard segment 4 and a top cover 6, the bottom segment 3 is fixed on the top of the platform 1, the standard segment 4 is fixed on the top of the bottom segment 3, and the top cover 6 is fixed On the top of the standard segment 4, the standard segment 4 includes a plurality of correspondingly superimposed standard segments, and a compartment plate 5 is provided between two adjacent standard segments, the bearing platform 1, the bottom segment 3, the standard segment Section 4, compartmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com