Buoy submerged floating oil absorption device

An absorption device and water slick oil technology, which can be used in general water supply conservation, water conservancy projects, and cleaning of open water surfaces, and can solve problems such as automatic collection of oil, water, and oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

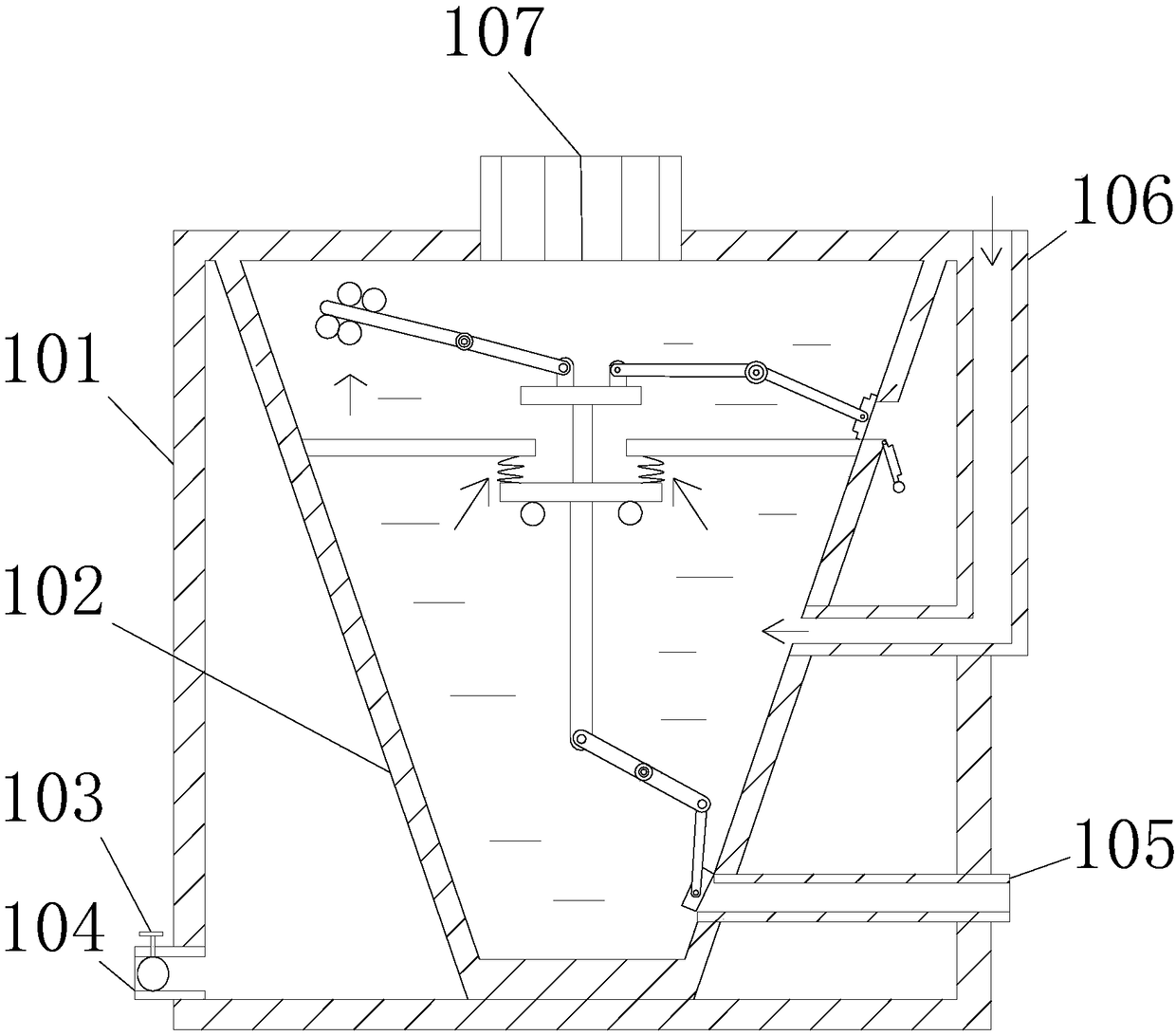

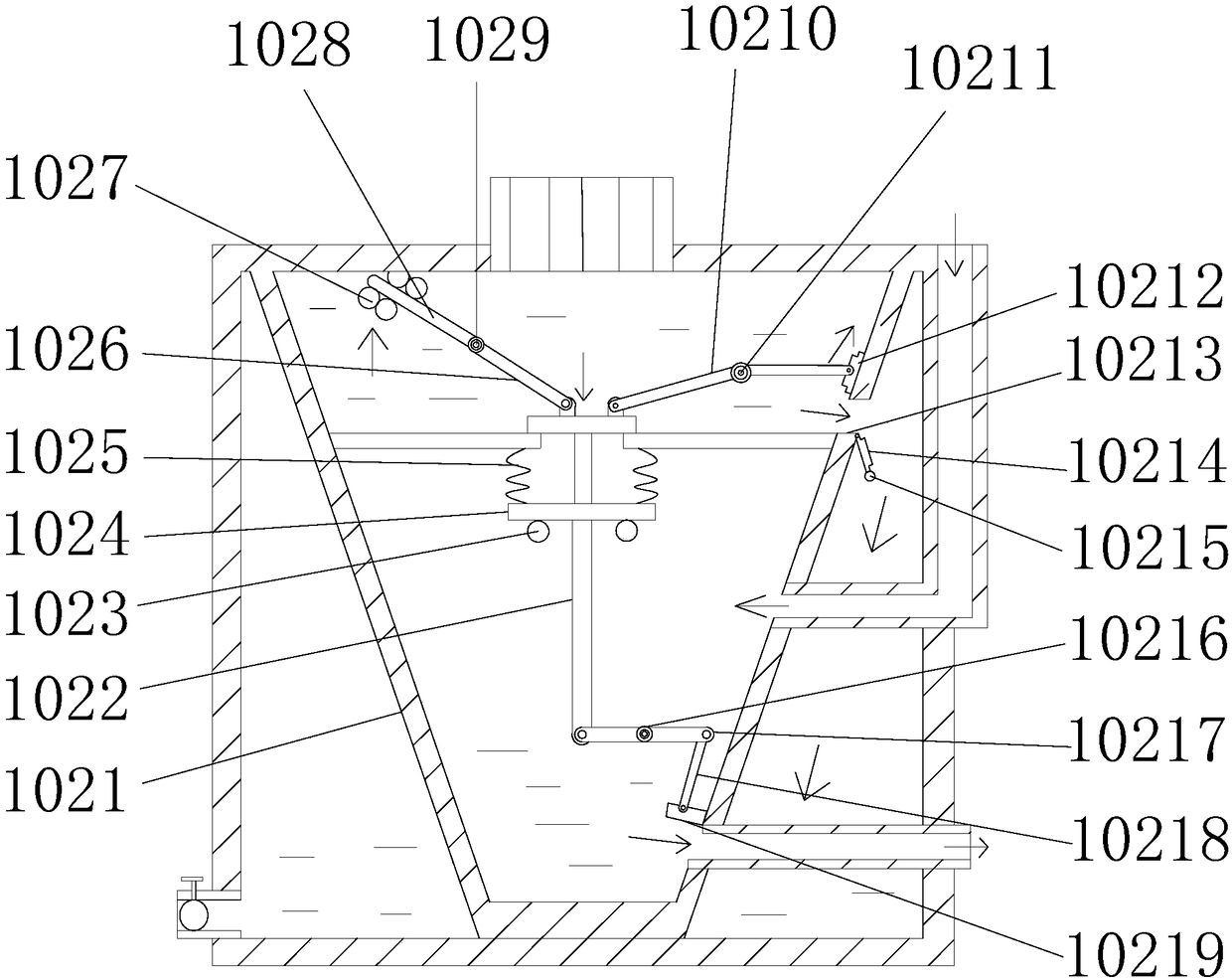

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

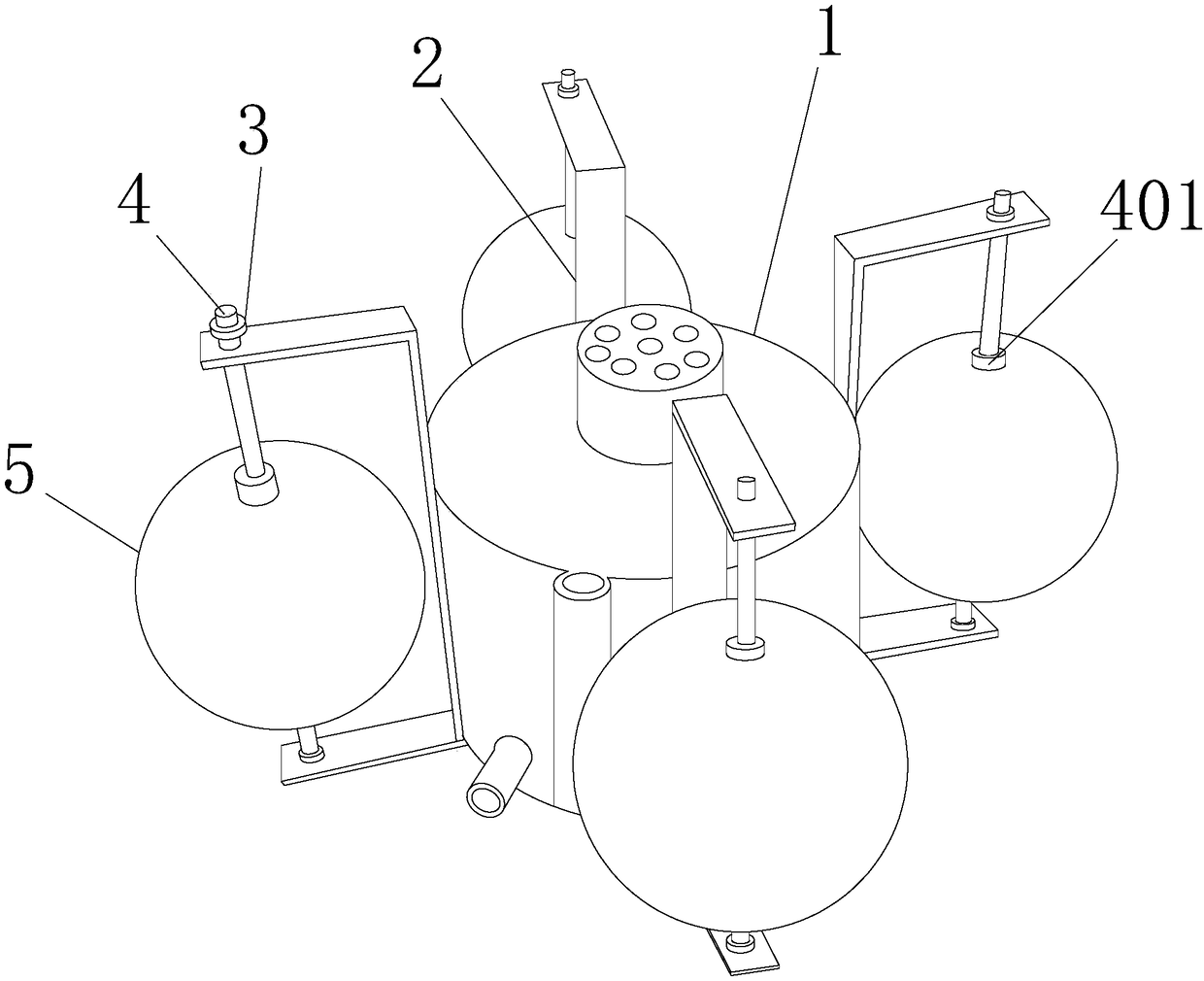

[0025] see Figure 1-Figure 4 , the present invention provides a buoy submerged oil slick absorbing device, the structure of which includes an oil slick absorbing barrel 1, a concave frame 2, a set nut 3, a float ball slide rod 4, and a large float ball 5;

[0026] The side surface of the oil slick absorption barrel 1 is vertically welded with four concave frames 2, and the concave frames 2 are distributed circularly and equidistantly around the oil slick absorption barrel 1, and the floating ball slider 4 vertically runs through the concave frame 2 up and down. Horizontal plates on both ends, the upper and lower ends of the floating ball slide bar 4 are provided with tightening nuts 3, the described floating ball sliding bar 4 and the set nut 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com