Heat pump unit closed type automatic cycle water cooling system

An automatic circulation and water-cooling system technology, applied in the direction of machines/engines, pump components, pump control, etc., can solve problems such as poor cooling effect, waste of water resources, complex structure, etc., to improve heat exchange efficiency, save water, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

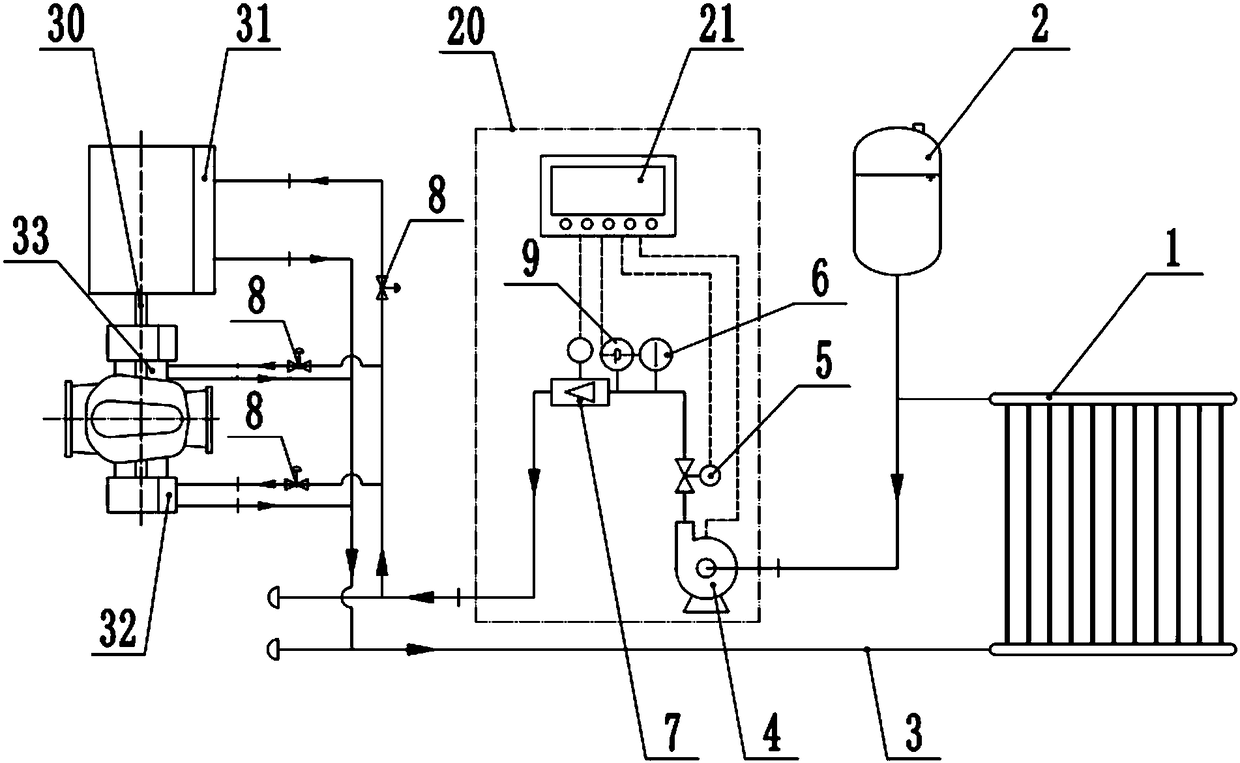

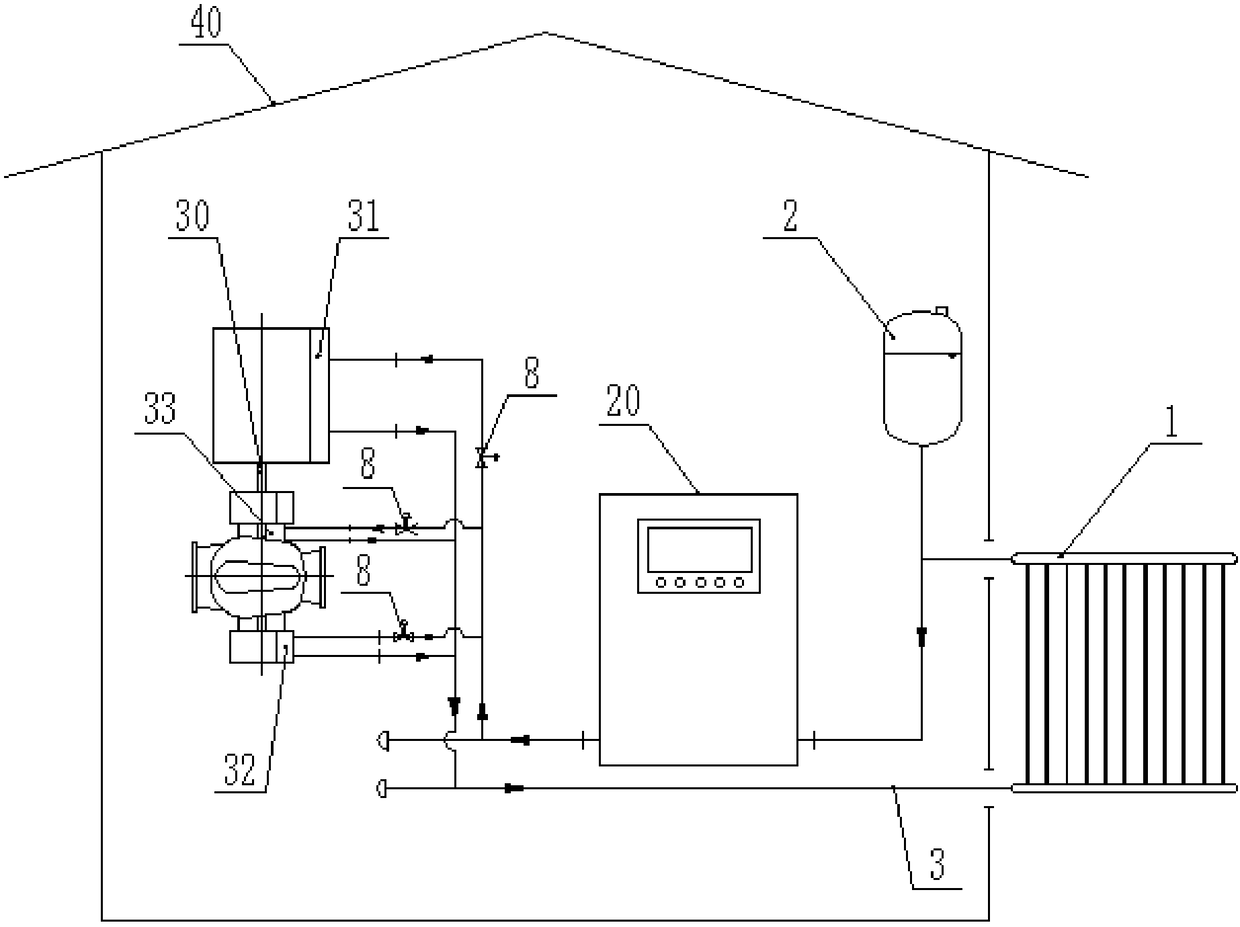

[0024] Such as figure 1 A heat pump unit closed automatic circulation water cooling system shown includes a radiator 1, a water supply tank 2, a booster pump 4, an electromagnetic stop valve 5, a temperature sensor 6 and a flow meter 7; the outlet of the radiator 1 passes through a pipeline It is connected with the water supply tank 2, the booster pump 4, the electromagnetic stop valve 5, the temperature sensor 6 and the flowmeter 7 in sequence; the outlet of the flowmeter 7 is provided with three branch pipelines, and the branch pipelines are respectively connected with the inlet of the motor water cooling chamber 31 and the bearing body water cooling chamber 32 The inlet is connected to the inlet of the mechanical seal water cooling chamber 33; the outlet of the motor water cooling chamber 31, the outlet of the bearing body wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com