Drying machine for textiles

A drying machine and drying box technology, applied in the textile field, can solve the problems of low efficiency, slow drying speed, inconvenient use, etc., and achieve the effect of simple overall structure, low processing and production, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

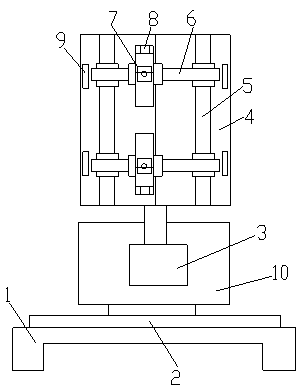

[0014] as attached figure 1 The shown textile dryer according to the present invention includes a drying box 1, a pressing assembly, a pressing plate 2, a hot air blowing device 3, an arc box 4, an air outlet pipe 5, a heating pipe 6, and a lifting cylinder 7 , a heating plate 8, a transfer roller 9 and a heating assembly; the two ends of the drying box 1 are provided with openings; the upper end of the opening is provided with a pressing assembly, and the lower end is provided with a pressing plate 2; the drying box 1 The upper end is provided with blowing hot air device 3; Said hot air blowing device 3 links to each other with the arc box 4 in drying box 1, and above-mentioned arc box 4 is provided with a plurality of outlet pipes 5; The bottom of described drying box 1 A plurality of heating pipes 6 are provided; the lower end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap