Start-up system of laser methane sensor with peak shifting opening function

A technology of methane sensor and opening function, which is applied in the field of starting system, can solve the problems of large starting current and sensor failure to start normally, and achieve the effects of improving starting ability, enhancing the effect of the invention, and obvious technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

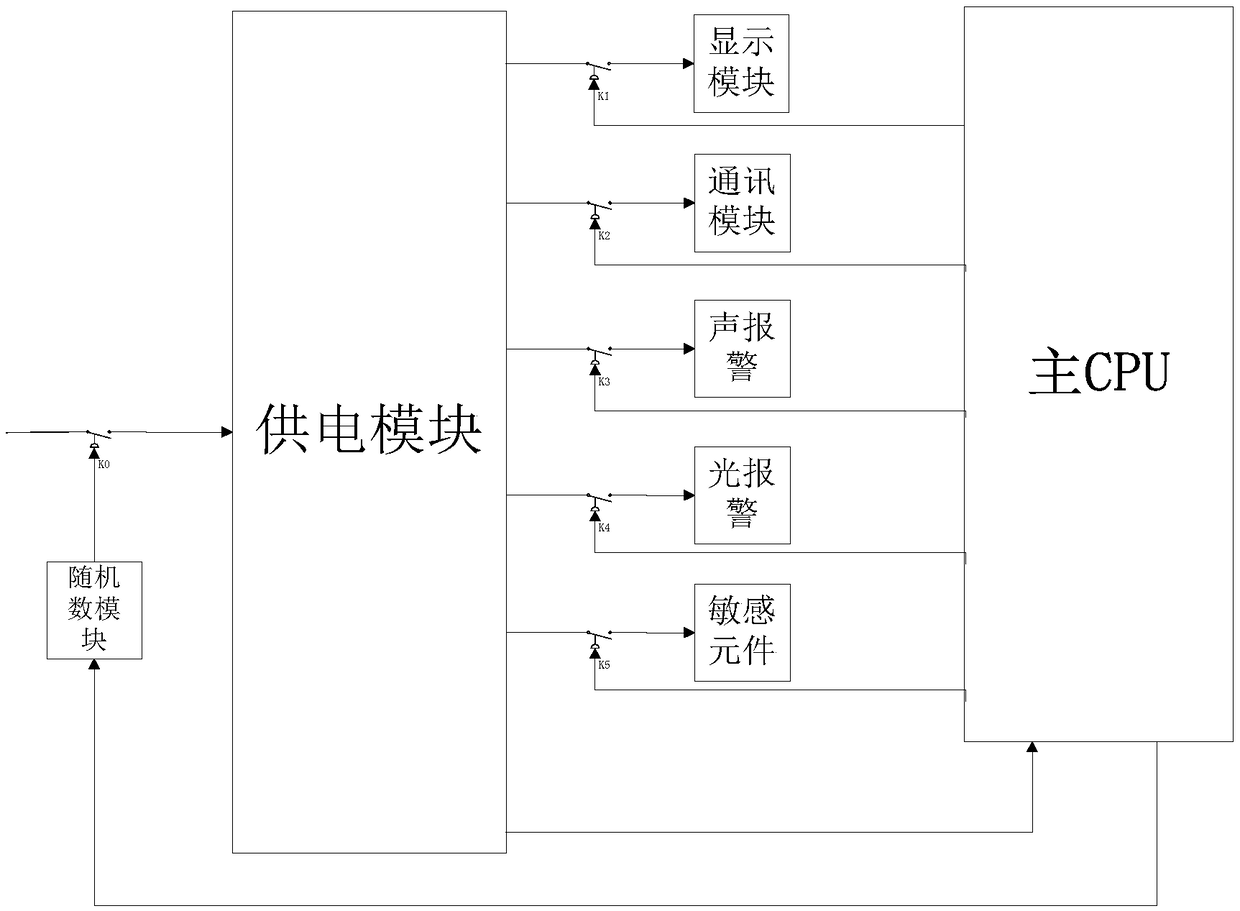

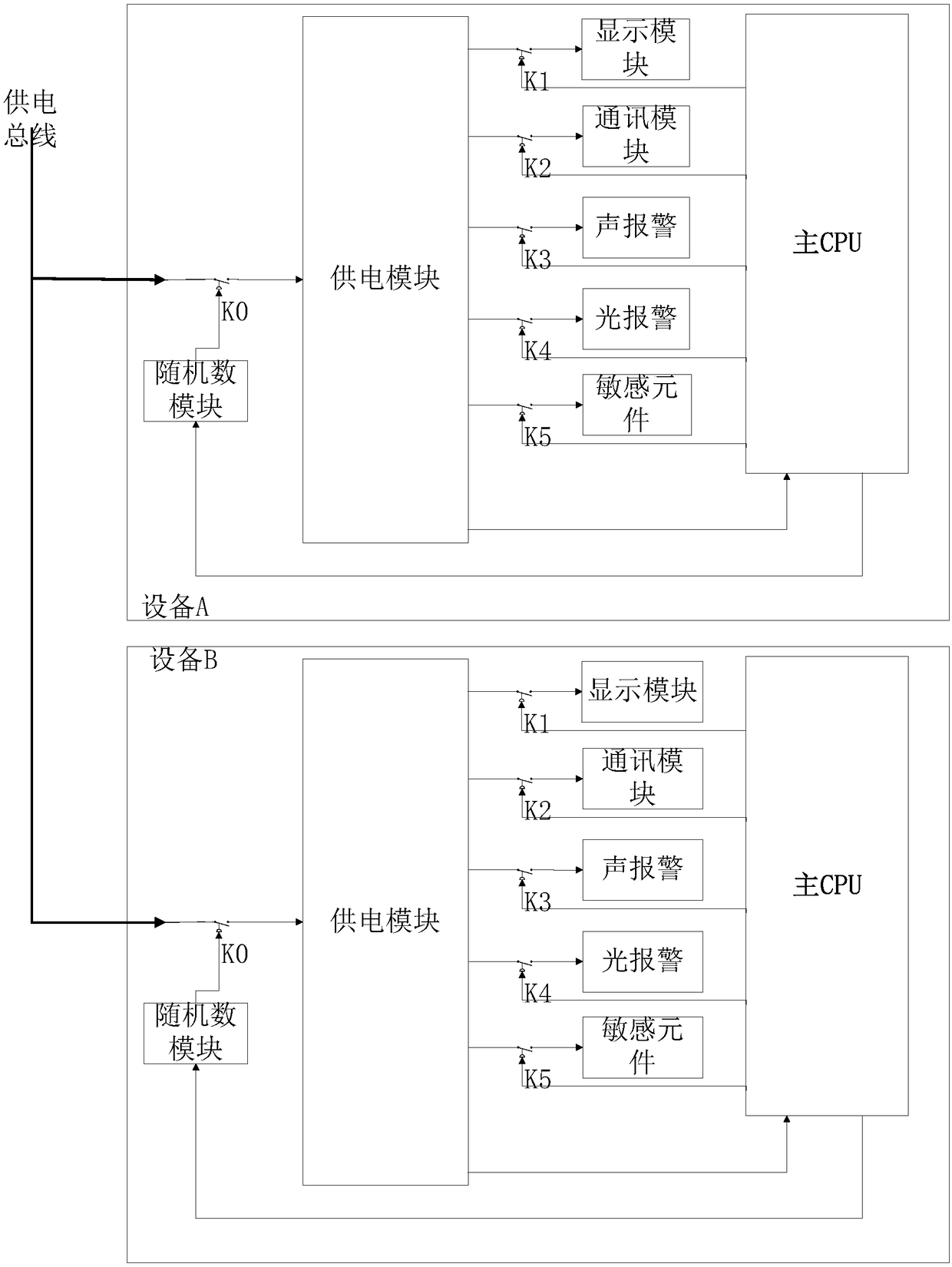

[0019] Such as figure 1 , 2 As shown, the start-up system of the laser methane sensor with the function of turning on the peak of the present invention includes a plurality of laser methane sensors, a power supply bus, a plurality of power supply modules, a plurality of switches K0 and a random number module, the laser methane sensor, the power supply module, The number of switches K0 and random number modules are equal. One end of the power supply bus is connected to the power supply, and the other end is connected to all switches K0 in parallel. Each switch K0 is connected to a power supply module, and one power supply module is connected to a laser methane sensor. A random number module is connected between the methane sensor and the switch K0. The multiple laser methane sensors are all provided with a main CPU, a display module, a communication module, an acoustic alarm module, a light alarm module and a sensitive element. The display module, communication module The module,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com