Wireless temperature measurement code-matching wall system

A technology of wireless temperature measurement and code wall, applied in the direction of control/adjustment system, non-electric variable control, instrument, etc., can solve the problems of unable to intervene in time, cannot realize wine cellar automation, temperature control and humidity control cannot be automated, etc., to achieve improvement The effect of user experience and precise production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

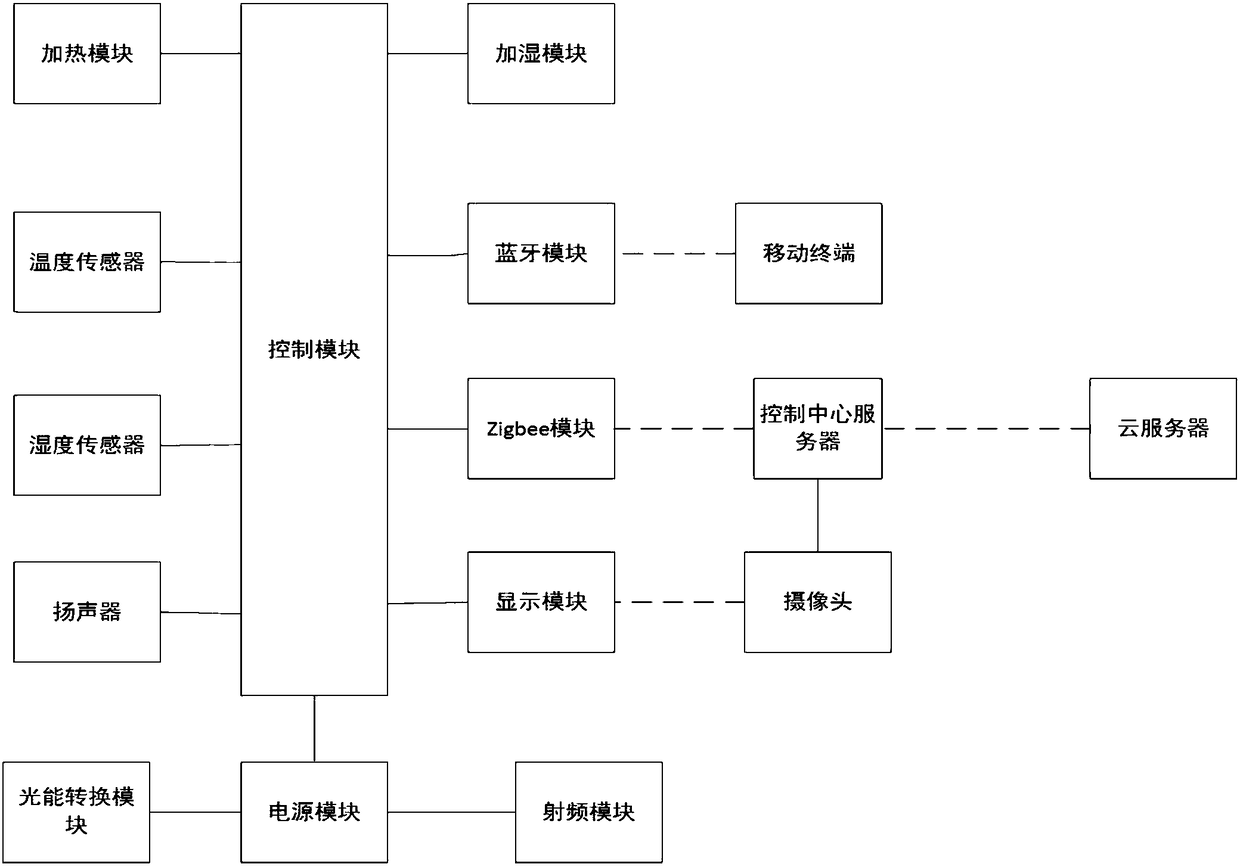

[0034] Such as figure 1 As shown, the present invention provides a wireless temperature measurement code wall system, including a control module, a heating module, a temperature sensor, a humidity sensor, a speaker, a power module, a display module, a ZigBee module, a Bluetooth module, a humidification module, and a light energy conversion module , radio frequency module, camera, control center server, cloud server, mobile terminal;

[0035] The control module is respectively connected with the heating module, temperature sensor, humidity sensor, speaker, power supply module, display module, ZigBee module, Bluetooth module and humidification module;

[0036] The power module is connected with the light energy conversion module and the radio frequency module;

[0037] Photoelectric conversion is the process of directly converting solar radiation energy into electrical energy through the photovoltaic effect. The principle of this process is that photons transfer energy to elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com