Simple insect specimen making method

A technique for making specimens and insects, applied in the field of experimental instruments, can solve the problems of short preservation time of specimens, high maintenance cost, easy air leakage at the sealing part, etc., and achieves the effects of low cost, low cost and not easy to be damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

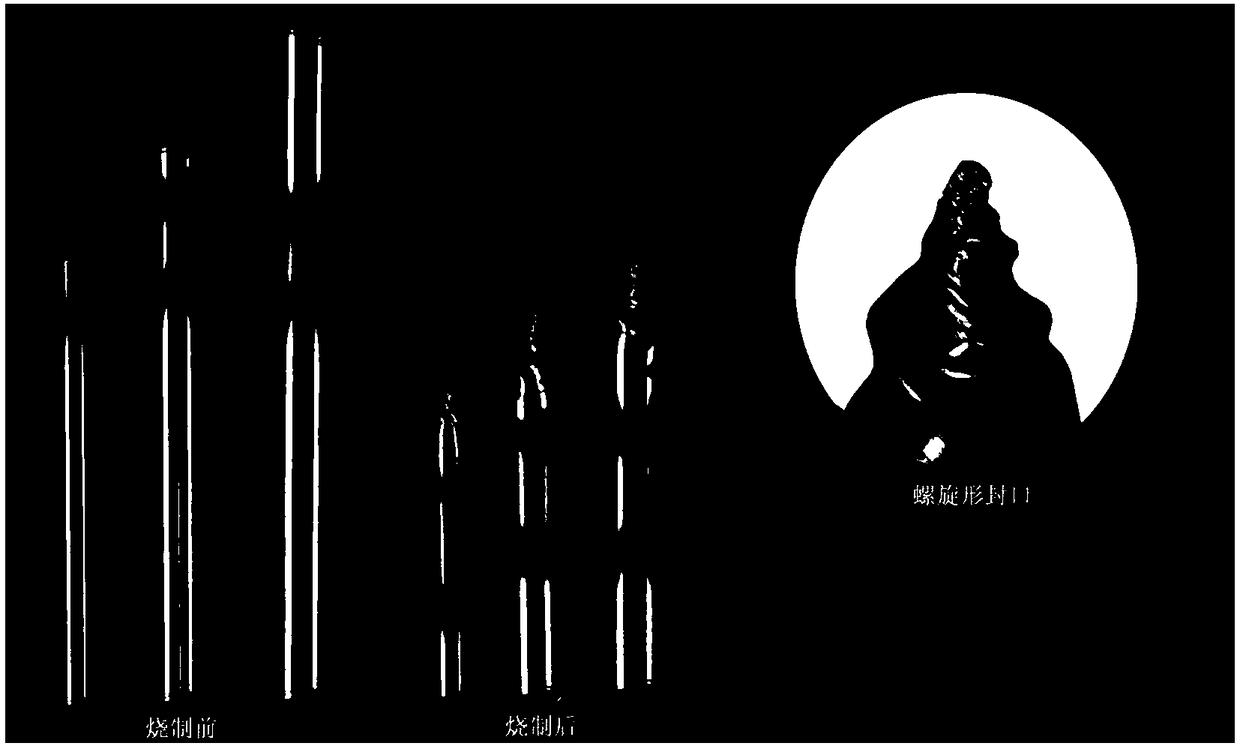

[0057] 1. Preliminary preparation of insect test tube specimens

[0058] (1) Physical specimens and processing

[0059] Select test tubes of different specifications and models according to physical specimens (such as eggs, larvae, pupae of insects, and some smaller adults).

[0060] Because the flame of the alcohol blowtorch is around 20mm, the diameter of the test tube should be ≤18mm, generally 10-15mm. If the diameter is too large, the tube wall will be heated unevenly.

[0061] The wall thickness of the test tube is ≤1.5mm. If the tube wall is too thick, it will make it difficult to rotate and stretch, and if the burning point is too thick, it will easily lead to cracking at the burning point during cooling. The wall thickness of the test tube is preferably 1.0-1.5mm It is advisable, this is because the tube wall is too thin, the test tube is easily damaged, and it is not easy to preserve.

[0062] Test tubes with a diameter of 10-13mm, the tube length is not less than ...

Embodiment 2

[0092] The difference between embodiment 2 and embodiment 1 is that during the trial screwing and screwing process, the hand wears heat-insulating safety gloves; and the shape of the spiral seal can be other shapes, which can be nearly conical or long cylindrical.

Embodiment 3

[0094] The difference between embodiment 3 and embodiment 1 is that the vise is replaced with a heat-resistant clamping device, including needle-nose pliers and iron clamps; the heating device (alcohol blowtorch) is replaced with other heating devices that can reach the same softening effect Including oxygen spray gun, butane spray gun, liquefied gas spray gun.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com