Wind power bus system

A wind power bus and wind tower technology, applied in the direction of cooling bus devices, fully enclosed bus devices, etc., can solve the problems of wind tower bus duct vibration, low heat dissipation efficiency, hidden dangers, etc. The effect of strengthening the seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

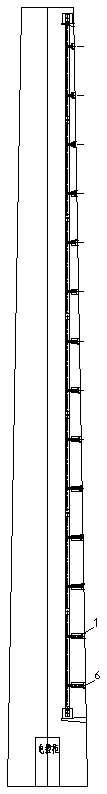

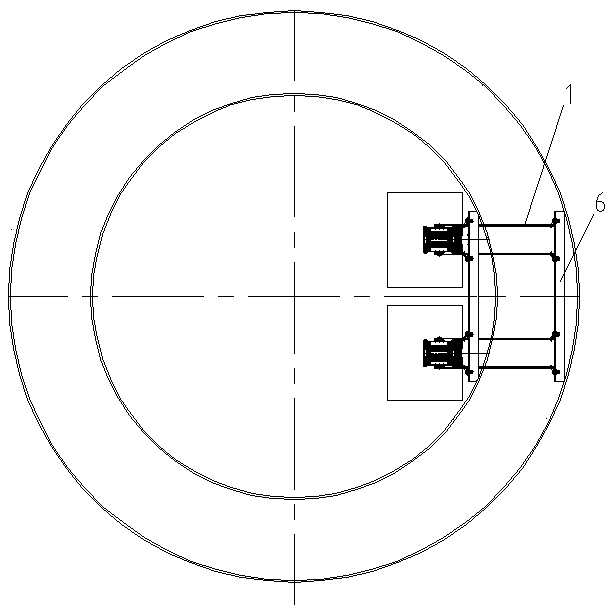

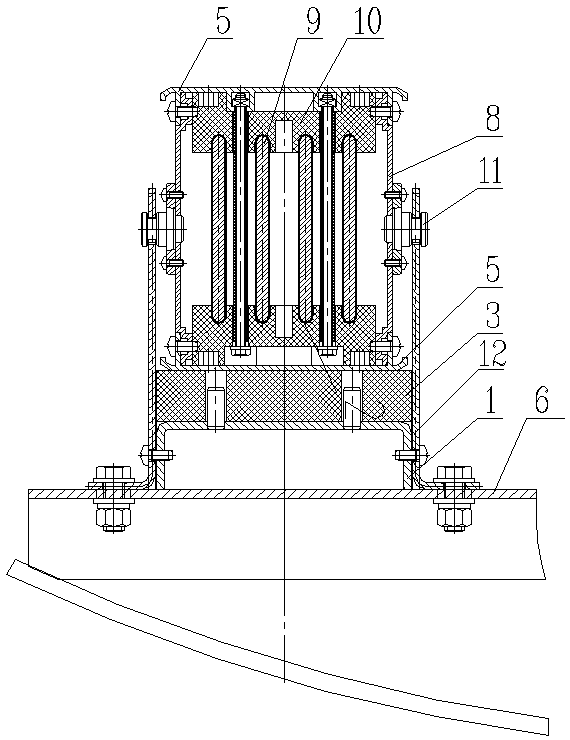

[0019] As shown in the figure, a wind power bus system includes a wind power bus installed inside the wind tower for the power transmission of the generator set, and a fixed installation structure for the wind power bus; the wind power bus includes a cover plate 5 and a side plate 8. The shell, and the phase line conductor 9 placed in the inner cavity of the shell, and the sections of the busbar are communicated through connectors 7, and the shell is clamped by a pair of vertical side plates 8 on both sides of a pair of horizontal cover plates 5 to limit the position The inner side of the ribs is formed, the center of the side plate 8 is provided with a mounting hole for the rotating shaft 11, and the two sides of the mounting hole for the rotating shaft 11 are provided with threaded holes; The mounting seat is fixedly installed on the side plate 8 through the threaded hole, and the rotating shaft 11 can rotate in the mounting seat and the mounting hole at the same time; the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com