Fabric disinfecting device

A technology for disinfection equipment and fabrics, which is applied in disinfection, sanitary equipment for toilets, water supply devices, etc., and can solve the problems of long disinfection process, unfavorable quality, and large water absorption of fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

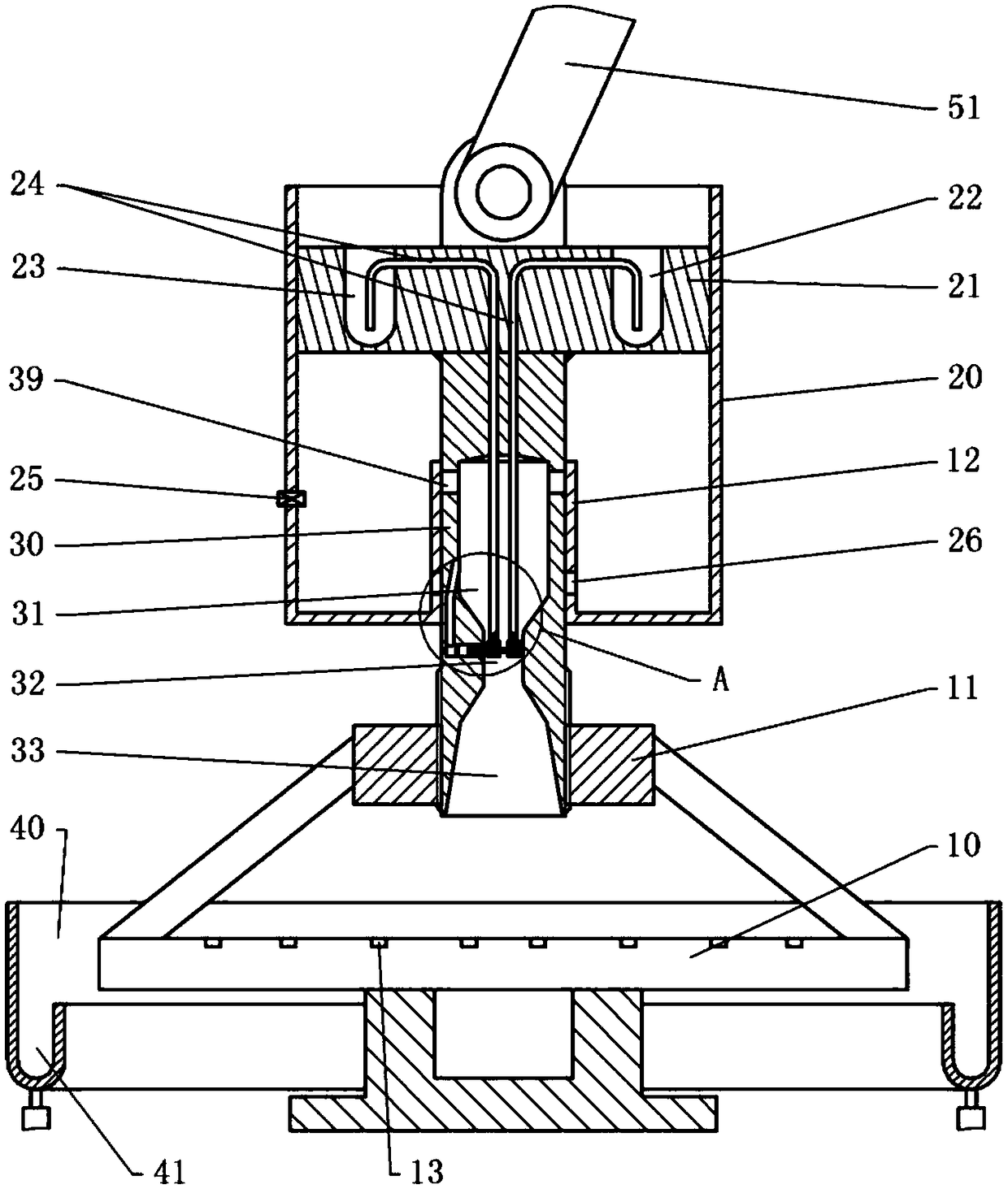

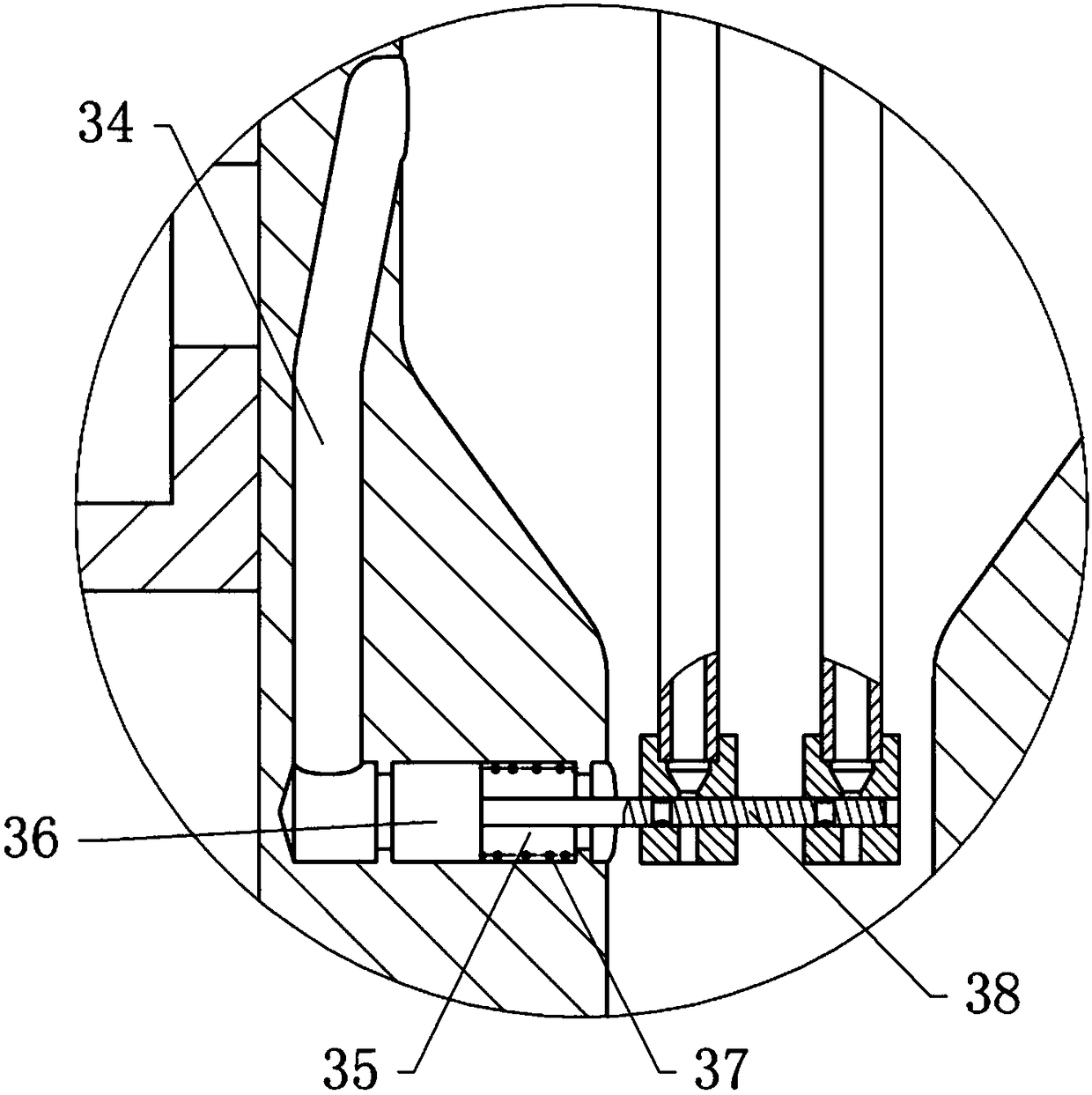

[0025] Such as figure 1 , figure 2 As shown, the cloth disinfection equipment includes a frame, an air box 20, a disinfection table 10 and a motor, the air box 20 and the motor are fixedly installed on the frame, the disinfection table 10 is a square platform, and the surface of the disinfection table 10 is provided with some The guide groove 13 is extended from the center to the periphery, and the disinfection table 10 is rotatably connected to the frame, and the disinfection table 10 is located under the air box 20 . A piston 21 is arranged in the air box 20 , the piston 21 can slide up and down in the air box 20 , and the upper part of the air box 20 is closed by the piston 21 . A crank is fixed on the output shaft of the motor, and the crank and the piston 21 are connected by a connecting rod 51, so that the crank, the piston 21 and the connecting rod 51 form a crank slider 36 mechanism; when the motor rotates, the piston 21 is driven up and down in the air box 20 recip...

Embodiment 2

[0031] The difference between the second embodiment and the first embodiment is that the pressure detection device in the second embodiment includes a controller and a pressure sensor, the valve is a solenoid valve, and both the pressure sensor and the solenoid valve are electrically connected to the controller. When the pressure at the throat drops, the pressure sensor will feed back a signal to the controller, and at the same time, the controller will send an execution signal to the solenoid valve, and the solenoid valve will open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com