Preparation method of medical antibacterial hydrocolloid dressing

An antibacterial water and colloid technology, which is applied in medical formula, medical science, capsule delivery, etc., can solve the problems of hydrocolloid dressing loss of integrity, poor antibacterial properties of hydrocolloid dressing, slow absorption of exudate, etc., to improve medical performance, Effect of reducing rigidity, improving solubility and degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

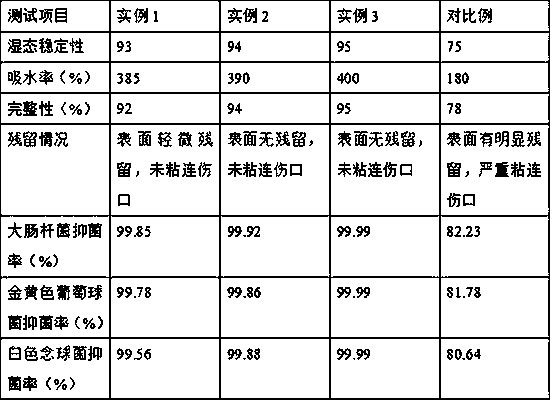

Examples

example 1

[0028] Add 6g of sodium alginate into a beaker filled with 200mL of deionized water, stir with a magnetic stirrer at a speed of 500r / min until the sodium alginate dissolves, and obtain a sodium alginate solution with a mass fraction of 2%. Sodium acid was dissolved in 10g of deionized water to obtain an oxidation solution; put the above oxidation solution into a three-necked flask with a dropping funnel and a stirrer, start the stirrer, start stirring at a speed of 300r / min, and then add the above alginic acid The sodium solution was put into the dropping funnel, and the sodium alginate solution was added dropwise to the three-necked flask at a dropping rate of 4 mL / min. After the dropwise addition, the three-necked flask was protected from light, and reacted at room temperature for 20 hours to obtain the oxidation product solution; Add 4 mL of ethylene glycol to the above-mentioned oxidation product liquid, stop the reaction for 2 hours, then add 0.8 g of sodium chloride to ob...

example 2

[0030] Take 8g of sodium alginate and add it to a beaker containing 220mL of deionized water, stir with a magnetic stirrer at a speed of 520r / min until the sodium alginate dissolves, and obtain a sodium alginate solution with a mass fraction of 3%. Sodium acid was dissolved in 11g of deionized water to obtain an oxidation solution; put the above oxidation solution into a three-necked flask with a dropping funnel and a stirrer, start the stirrer, start stirring at a speed of 400r / min, and then add the above alginic acid The sodium solution was put into the dropping funnel, and the sodium alginate solution was added dropwise to the three-necked flask at a dropping rate of 5 mL / min. After the dropwise addition, the three-necked flask was protected from light, and reacted at room temperature for 22 hours to obtain the oxidation product solution; Add 4mL of ethylene glycol to the above-mentioned oxidation product solution, stop the reaction for 2.5h, then add 0.9g of sodium chloride...

example 3

[0032] Add 10g of sodium alginate into a beaker filled with 250mL of deionized water, stir with a magnetic stirrer at a speed of 550r / min until the sodium alginate dissolves, and obtain a sodium alginate solution with a mass fraction of 4%. Sodium acid was dissolved in 12g of deionized water to obtain an oxidation solution; put the above oxidation solution into a three-necked flask with a dropping funnel and a stirrer, start the stirrer, start stirring at a speed of 500r / min, and then add the above alginic acid The sodium solution was put into the dropping funnel, and the sodium alginate solution was added dropwise to the three-necked flask at a dropping rate of 6 mL / min. After the dropwise addition, the three-necked flask was protected from light, and reacted at room temperature for 24 hours to obtain the oxidation product solution; Add 5mL of ethylene glycol to the above-mentioned oxidation product solution, terminate the reaction for 3h, then add 1.0g of sodium chloride to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com