Rectifying tower beacon tower control method

A control method and rectification tower technology, applied in the direction of distillation adjustment/control, program control, computer control, etc., can solve the problems affecting the stable steam volume in the tower bottom and unfavorable operation of the rectification tower system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] With regard to the new method proposed by the present invention, an example of industrial application will be described below.

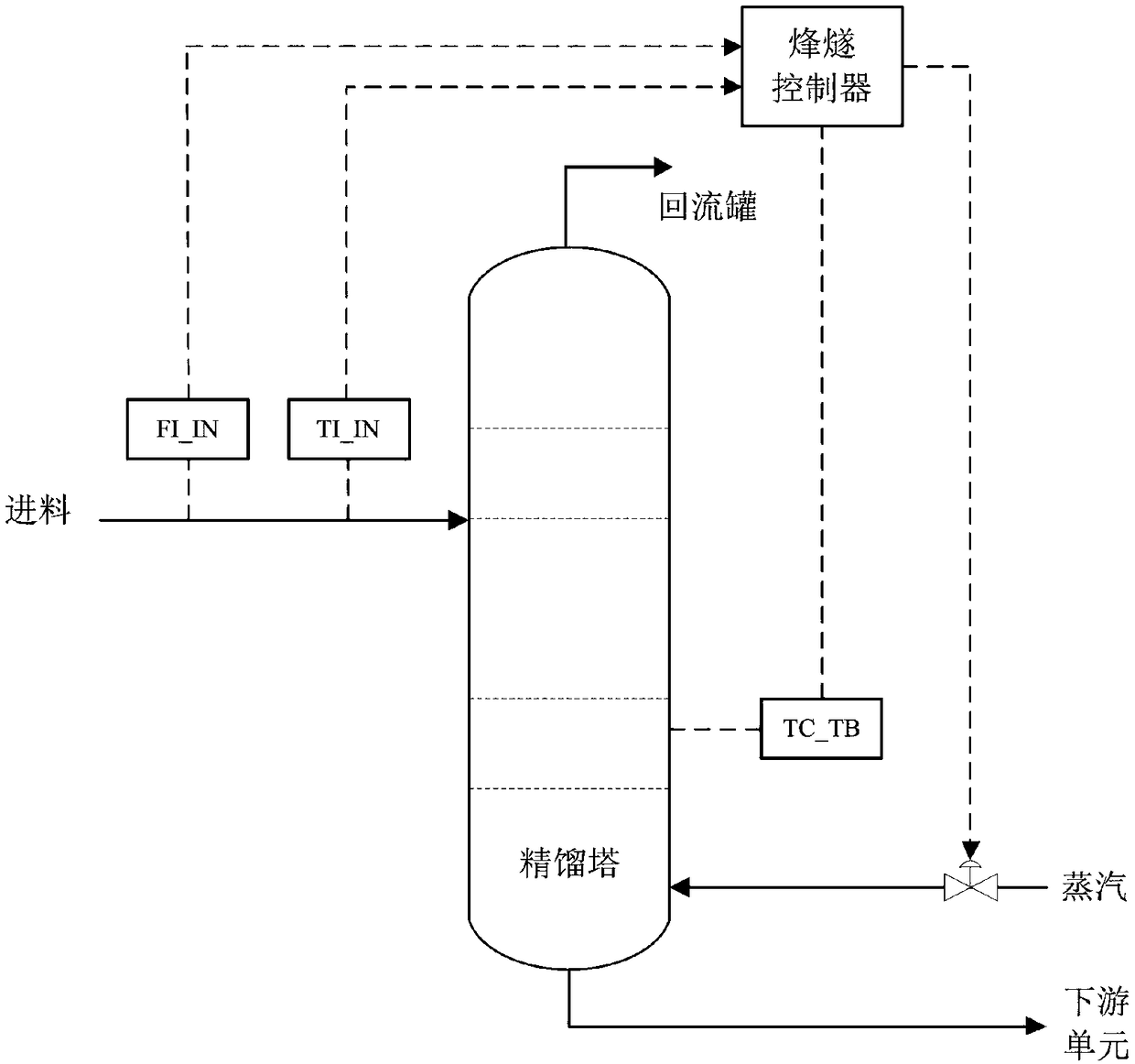

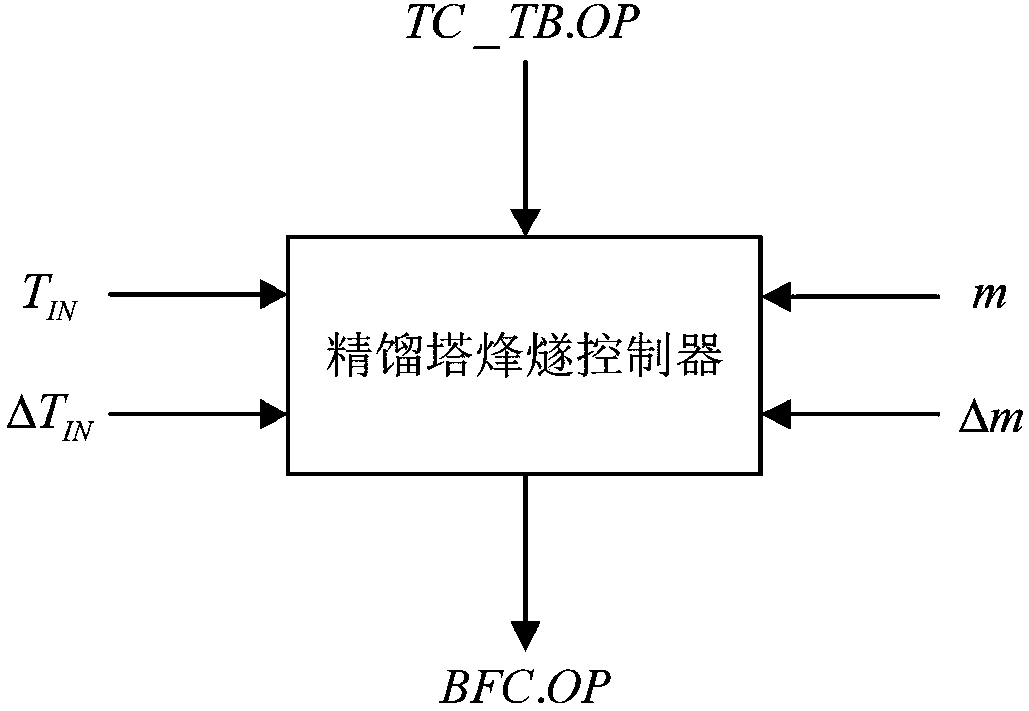

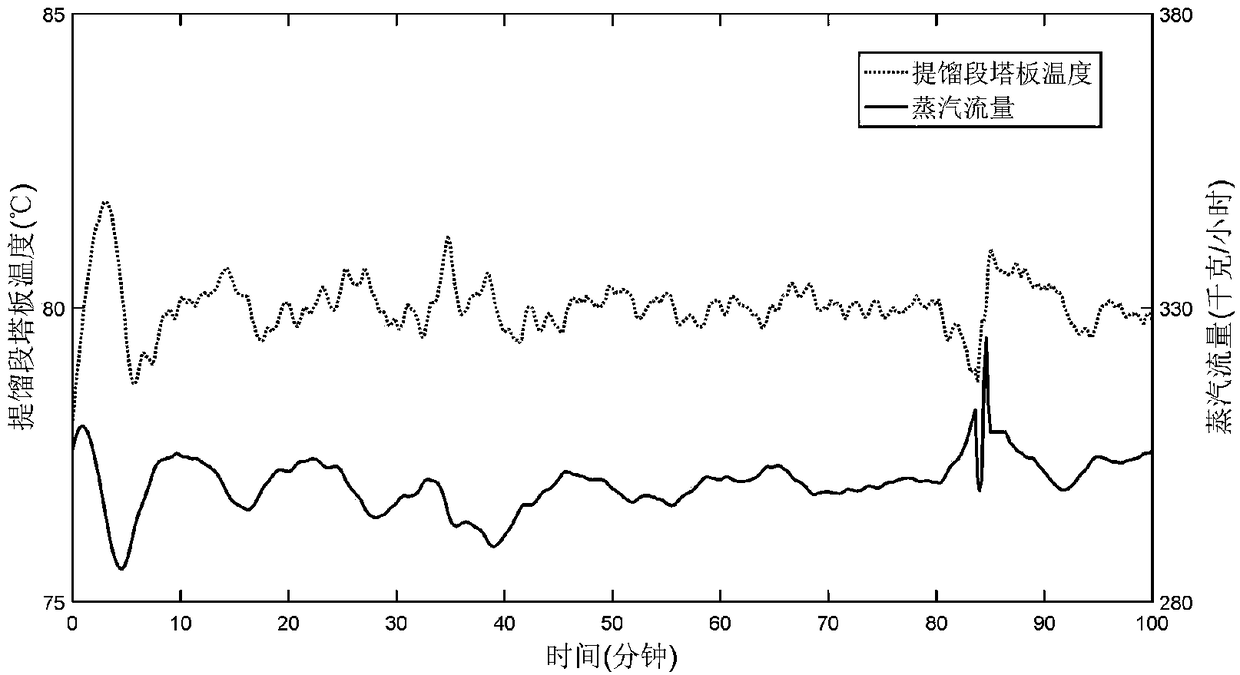

[0030] The debutanizer of an ethylene plant is a conventional rectification tower. The debutanizer functions to separate the upstream feed into the C4 component at the top of the tower and the C5 and C5 heavy components in the bottom of the tower. The tower system The heat source is provided by superheated steam. The schematic diagram of the debutanizer is as follows figure 1 As shown, the tower feed is respectively equipped with a flow measuring instrument FI_IN and a temperature measuring instrument TI_IN to measure the changes in the inlet oil of the debutanizer in real time, and the tray temperature TC_TB of the stripping section is adjusted by a steam valve. Affected by the fluctuations in the upstream of the debutanizer, the oil flow and temperature at the inlet of the tower will also fluctuate frequently, which in turn affects the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com