A device and method for precision forming of sheet material controlled by sub-area soft mold

A precision forming and sub-regional technology, applied in the field of sheet metal forming, to achieve the effect of reducing difficulty, increasing application value, and improving the formability of sheet metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

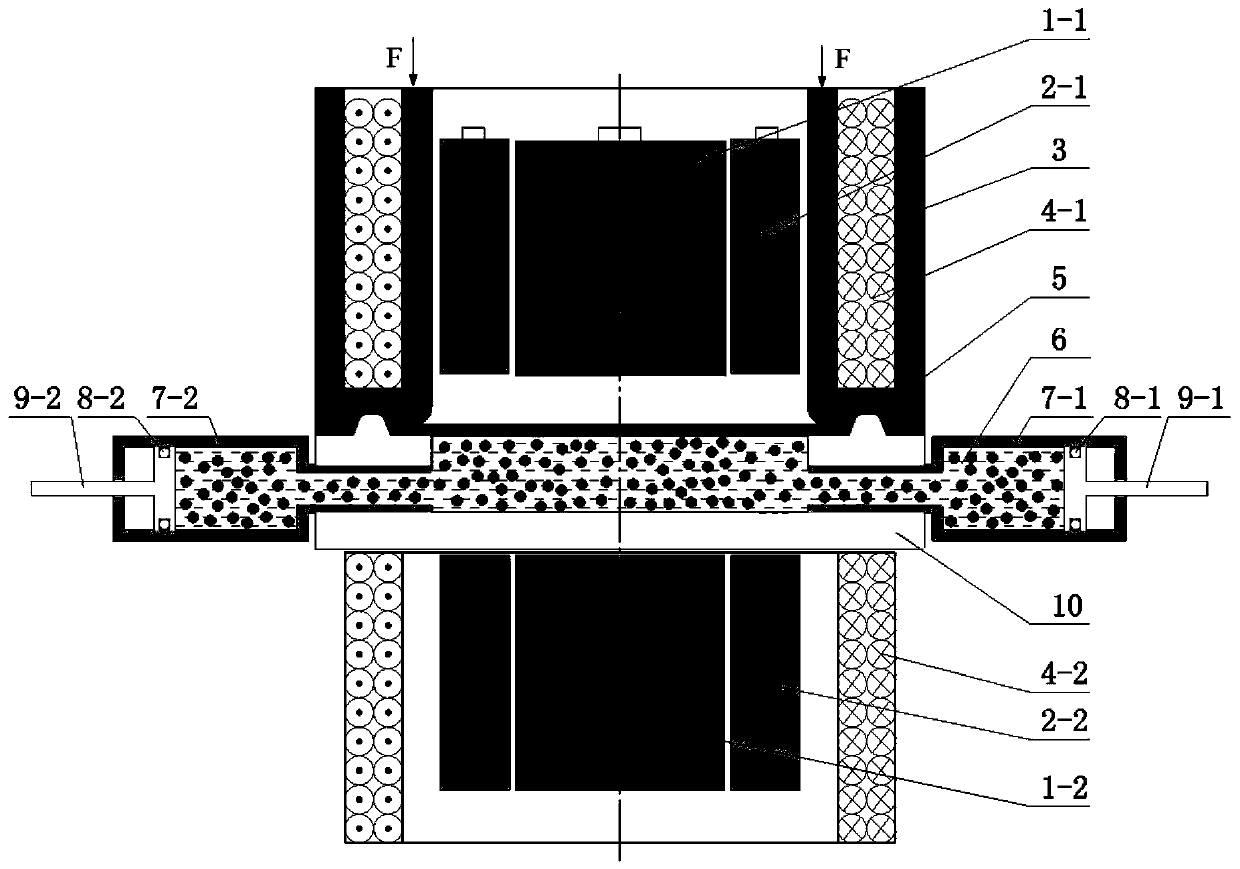

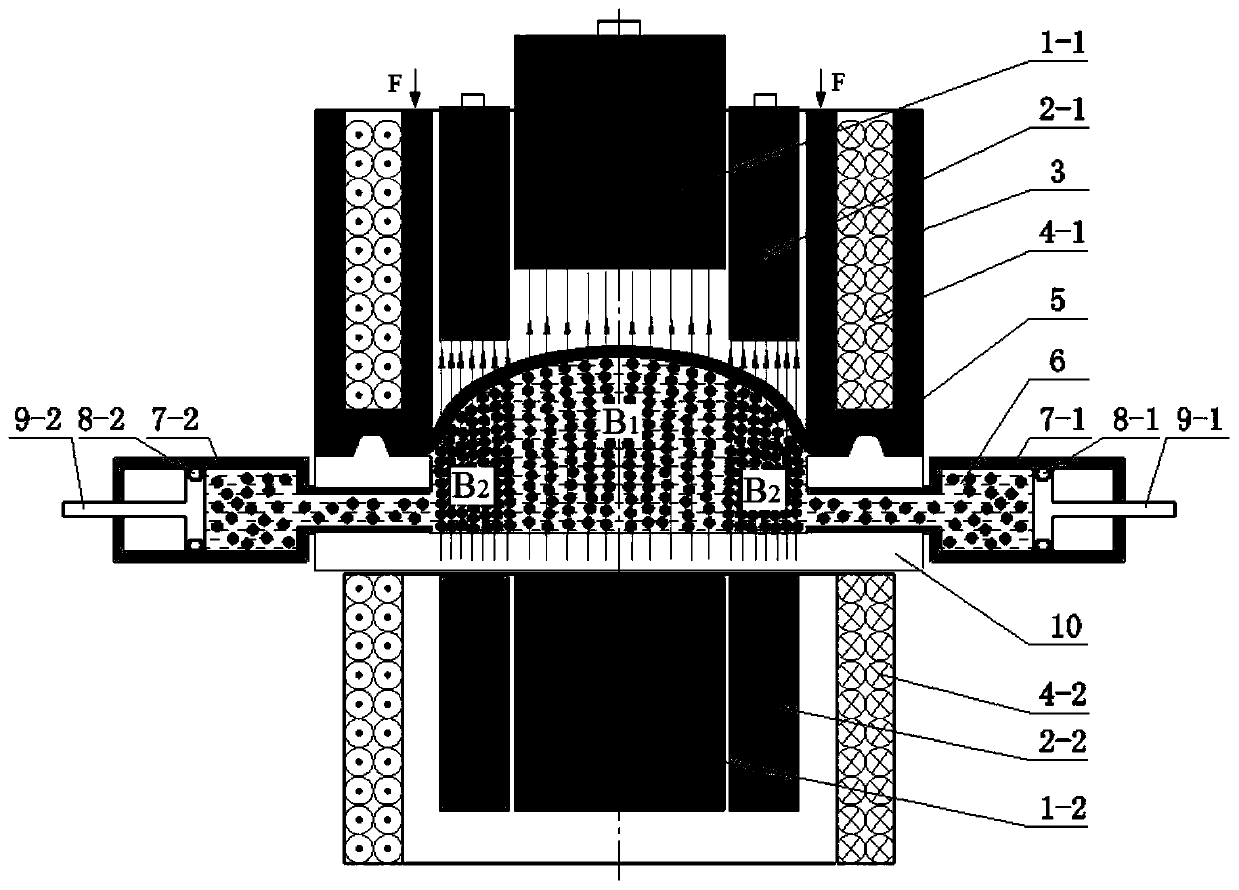

[0030] A device for precise forming of plates controlled by sub-regional soft molds, including a first iron core assembly, a die 3, a first coil 4-1, a second coil 4-2, a plate 5, a magnetorheological fluid 6, a plunger cylinder, Plunger, medium cylinder 10, second iron core assembly;

[0031] The bottom of the medium cylinder 10 is closed, the upper part is provided with an opening, the plunger cylinder and the medium cylinder 10 are connected, the plunger is installed in the plunger cylinder, the magnetorheological fluid 6 is filled in the inner cavity of the medium cylinder 10 and the plunger cylinder, and the die 3 is located above the medium cylinder 10, and the plate to be formed is clamped between the die 3 and the medium cylinder 10;

[0032] The die 3 is provided with a first coil 4-1, the second coil 4-2 is located below the medium cylinder and corresponding to the first coil 4-1, the first iron core assembly is located inside the first coil 4-1, and the second The ...

Embodiment 2

[0045] Such as figure 1As shown, a sub-area soft mold control plate precision forming device includes a first cylindrical iron core 1-1, a first annular iron core 2-1, a die 3, a first coil 4-1, a plate 5, and a magnetic current Liquid changing 6, first plunger cylinder 7-1, first sealing ring 8-1, first plunger 9-1, medium cylinder 10, second cylindrical iron core 1-2, second annular iron core 2-2 and a second coil 4-2;

[0046] The medium cylinder 10 is closed at the bottom and open at the top, and is provided with a bead holder. There are two round holes on the side wall, which are connected with the first plunger cylinder 7-1 and the second plunger cylinder 7-2. The die 3 is located above the medium cylinder 10, and the plate to be formed is clamped between the die 3 and the medium cylinder 10. An annular groove is provided inside the die 3, and the first coil 4-1 is placed inside, and the second coil 4-2 and The first coil 4 - 1 is placed correspondingly and is located ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com