Class-A non-combustible thermal insulation board and preparation method thereof

A thermal insulation board and room temperature technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems that the industrial structure is difficult to meet the building construction, and achieve the effect of blocking the conduction of heat and the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

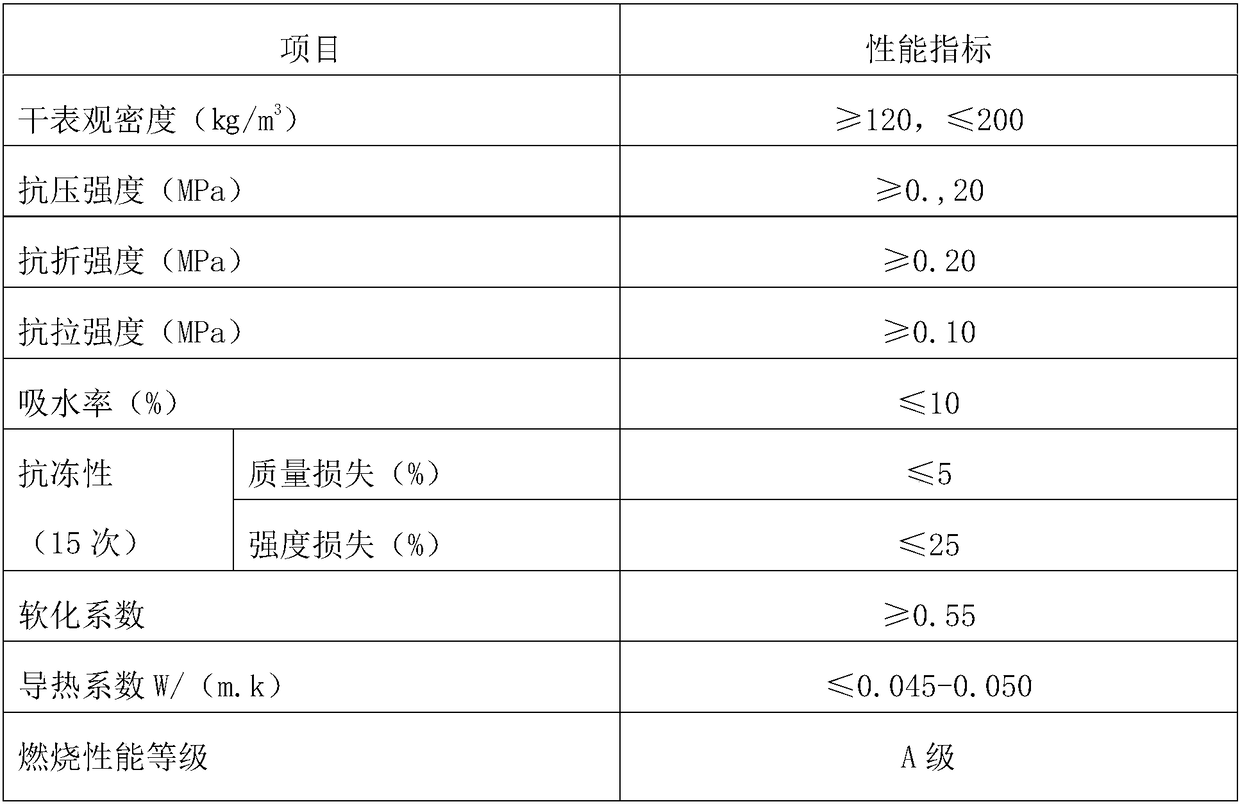

Embodiment 1

[0028] A grade A non-combustible insulation board, characterized in that it consists of the following components by weight:

[0029] 22 parts of organic particles;

[0030] 78 parts of inorganic particles;

[0031] 100 parts of water.

[0032] As a major improvement of the technical solution of this embodiment, the organic particles are modified polyphenylene particles.

[0033] As a major improvement of the technical solution of this embodiment, the inorganic particles include light aggregate and a viscosity modifier, and the weight ratio of the light aggregate and viscosity modifier is 80:20.

[0034] Specifically, the use temperature of the non-combustible insulation board provided in this embodiment can reach 1000°C, and the melting point can reach above 1500°C.

[0035] It will not soften and deform, drip and flow, or fall off in high temperature and fire.

[0036] After being fired, there is almost no loss of physical strength and thermal insulation performance, and ...

Embodiment 2

[0040] A preparation method of Class A non-combustible insulation board, comprising the following steps:

[0041] 1) 22 parts of organic particles, 78 parts of inorganic particles, and 100 parts of water are mixed evenly and then put into a high-speed mixer and stirred for 15 minutes;

[0042] 2) Put the mixture in step 1) into a molding tool or molding equipment, pressurize at 20T for 24 hours;

[0043] 3) After the pressing is completed, place it at room temperature for 7 days to preserve the sample;

[0044] 4) Cut the finished product with sample preservation into insulation boards with a length of 1.2 meters, a width of 0.6 meters and a height of 0.3 meters.

[0045] As a major improvement of the technical solution of this embodiment, the molding temperature in step 2) is 0-30°C.

[0046] As a major improvement of the technical solution of this embodiment, the room temperature in step 3) is 0-30°C.

[0047] As a major improvement of the technical solution of this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com