Nano fireproof polystyrene foam board and preparation method thereof

A technology of polystyrene foam and polystyrene, which is applied in the field of building fire protection and heat insulation, can solve the problems of high construction cost, water absorption, waste of resources, etc., and achieve the effects of filling technical gaps, reducing costs, and improving fire safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

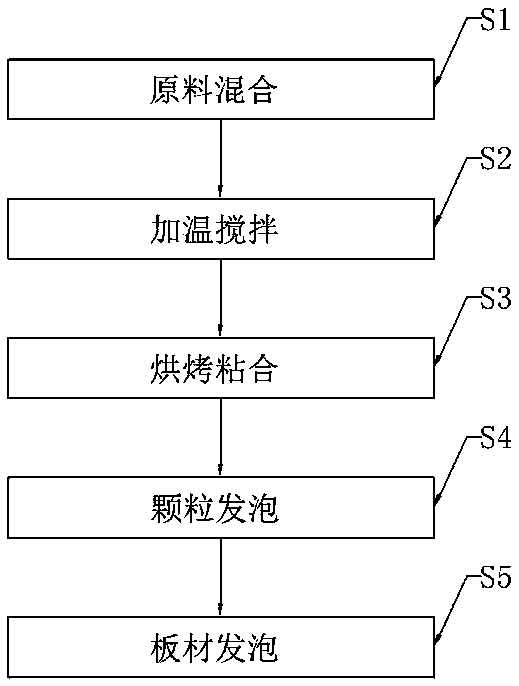

[0043] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0044] see figure 1 , the preparation method of a kind of nano fireproof polystyrene foam board of the present invention, comprises following synthetic steps:

[0045] S1. Mixing of raw materials: 40-50 parts of polystyrene raw material, 40-50 parts of fumed silica, 2-5 parts of nano-aerogel, and 2-5 parts of graphite are mixed in parts by mass. Fully mix ethylene and 2-10 parts of white high-temperature ceramic glaze;

[0046] S2, heating and stirring: put the mixed material in a stirring device with electric heating function to heat up and stir, so that the material is fully mixed, the temperature in the stirring device is 50-70 ° C, and the stirring time is 10-20 minutes;

[0047] S3. Baking and bonding: put the evenly stirred polystyrene material in the oven and continue to heat up and bake to make the polys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com