Oil-resistant fireproof rubber material for peroxide vulcanized hose assembly and preparation method of oil-resistant fireproof rubber material

A technology of peroxide and hose assembly, which is applied in the field of oil-resistant fire-resistant rubber compound and its preparation, can solve the problems that the barrier layer is difficult to heat insulation, fire-resistant, oil-resistant, poor in fire-resistance, limited in application occasions, etc., so as to prevent flames. The effect of penetration, meeting environmental protection requirements and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0030] A preparation method of oil-resistant fire-resistant rubber compound for peroxide vulcanized hose assembly, comprising the following steps:

[0031] (1) premixing silicone rubber with fluorosilicone rubber and phenyl silicone rubber on a rubber mixer to obtain a premixed base rubber;

[0032] (2) Gradually add flame retardant fillers (aluminum hydroxide, magnesium hydroxide, mica powder, boron nitride, alumina, zinc oxide), fluxes (glass powder, short glass fiber, aromatic Fibre filaments), add chloroplatinic acid solution and coupling agent dropwise, and finally add peroxide vulcanizing agent, after mixing uniformly, a mixed rubber is obtained;

[0033] (3) The rubber compound is vulcanized and molded to obtain oil-resistant and fire-resistant rubber products. The vulcanization molding temperature is 160-230°C, the pressure is 0-15MPa, and the time is 2-15 minutes.

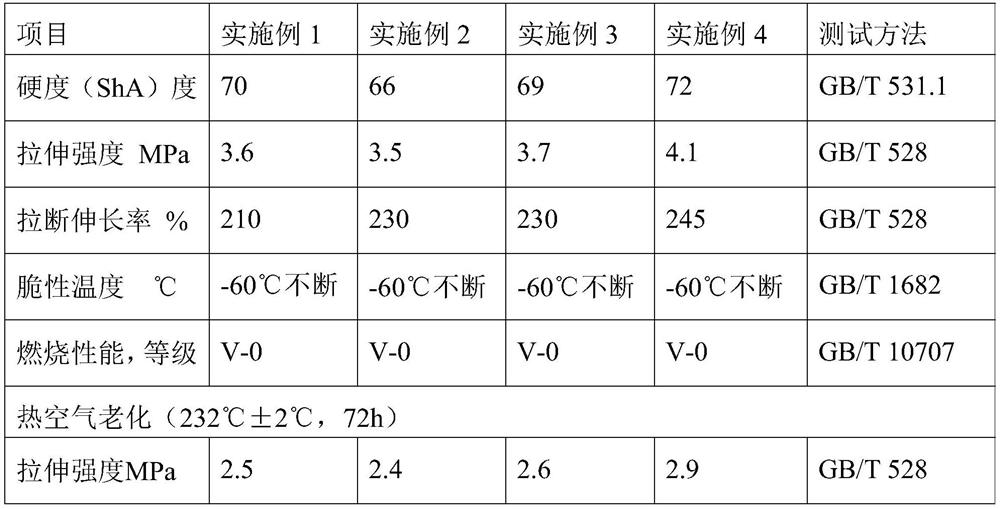

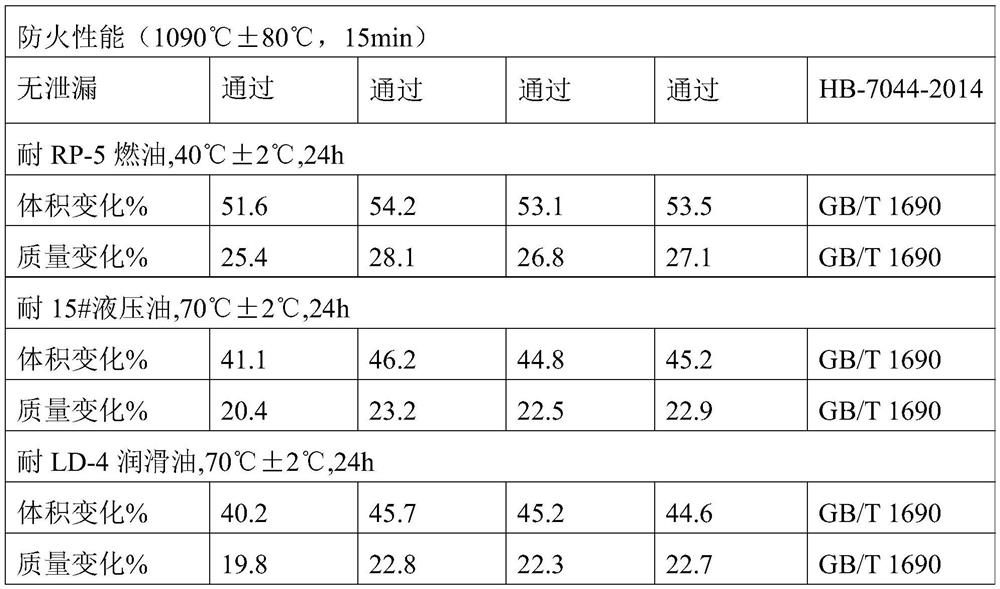

[0034] Table 1: Selection of raw materials in each embodiment (unit: kg)

[0035] Example ...

Embodiment 5

[0042] A preparation method of oil-resistant fire-resistant rubber compound for peroxide vulcanized hose assembly, comprising the following steps:

[0043] (1) premixing 30kg of silicone rubber with 40kg of fluorosilicone rubber and 30kg of phenyl silicone rubber on a rubber mixer to obtain a premixed base rubber;

[0044] (2) Gradually add flame retardant filler (10kg of aluminum hydroxide, 5kg of magnesium hydroxide, 5kg of mica powder, 5kg of boron nitride, 2kg of alumina, 1kg of zinc oxide), flux (10kg of glass powder) to the premixed base glue , glass fiber staple filament 5kg, aramid fiber staple filament 5kg), and dropwise add 1kg of chloroplatinic acid solution and 2kg of coupling agent, finally add 1.2kg of peroxide vulcanizing agent, and obtain mixed rubber after mixing evenly;

[0045] (3) The rubber compound is vulcanized and molded to obtain oil-resistant and fire-resistant rubber products. The vulcanization molding temperature is 160-230°C, the pressure is 0-15MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com