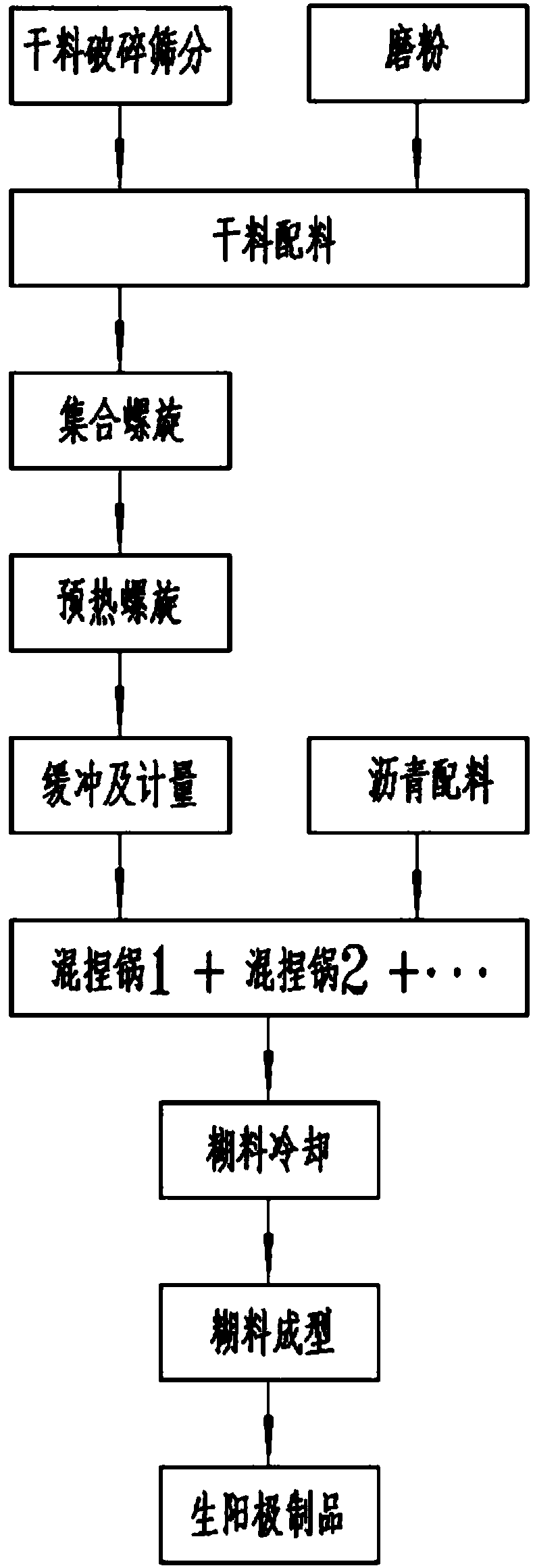

Continuous preheating and discontinuous mixed kneading production process

A production process and kneading technology, which is applied in the field of aluminum electrolysis, can solve problems such as oil leakage, potential safety hazards, and low preheating temperature of dry materials, and achieve the effects of improving anode quality, eliminating potential safety hazards, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] as attached figure 1 As shown, the petroleum coke, residual poles, and raw materials are crushed by the crusher to a particle size of less than 20mm, and then enter the multi-layer vibrating screen, and the materials of different particle sizes obtained through screening are respectively entered into the batching bins; The unbalanced material on a layer of sieve enters the milling system, and the powder with a particle size of less than 0.075mm with a mass percentage greater than 70% is obtained, and then the powder is sent to the powder bin through a chute or conveying equipment. The dry material in each batching bin is measured by the continuous batching scale and then enters the assembly screw. After the initial mixing of various ingredients by the assembly screw, it enters the continuous preheating screw. Enter the kneading pot for high-temperature kneading. The number of kneading pots is determined according to the production scale. After the kneading is completed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com