Standard gas generation system and method for calibrating or verifying exhaust-gas telemetry system

A generation system and telemetry system technology, applied in the field of standard gas generation system, can solve the problems of reducing detection accuracy, deviation of system detection results, inability to simulate exhaust gas diffusion, etc., achieving real-time calibration and verification, and improving measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

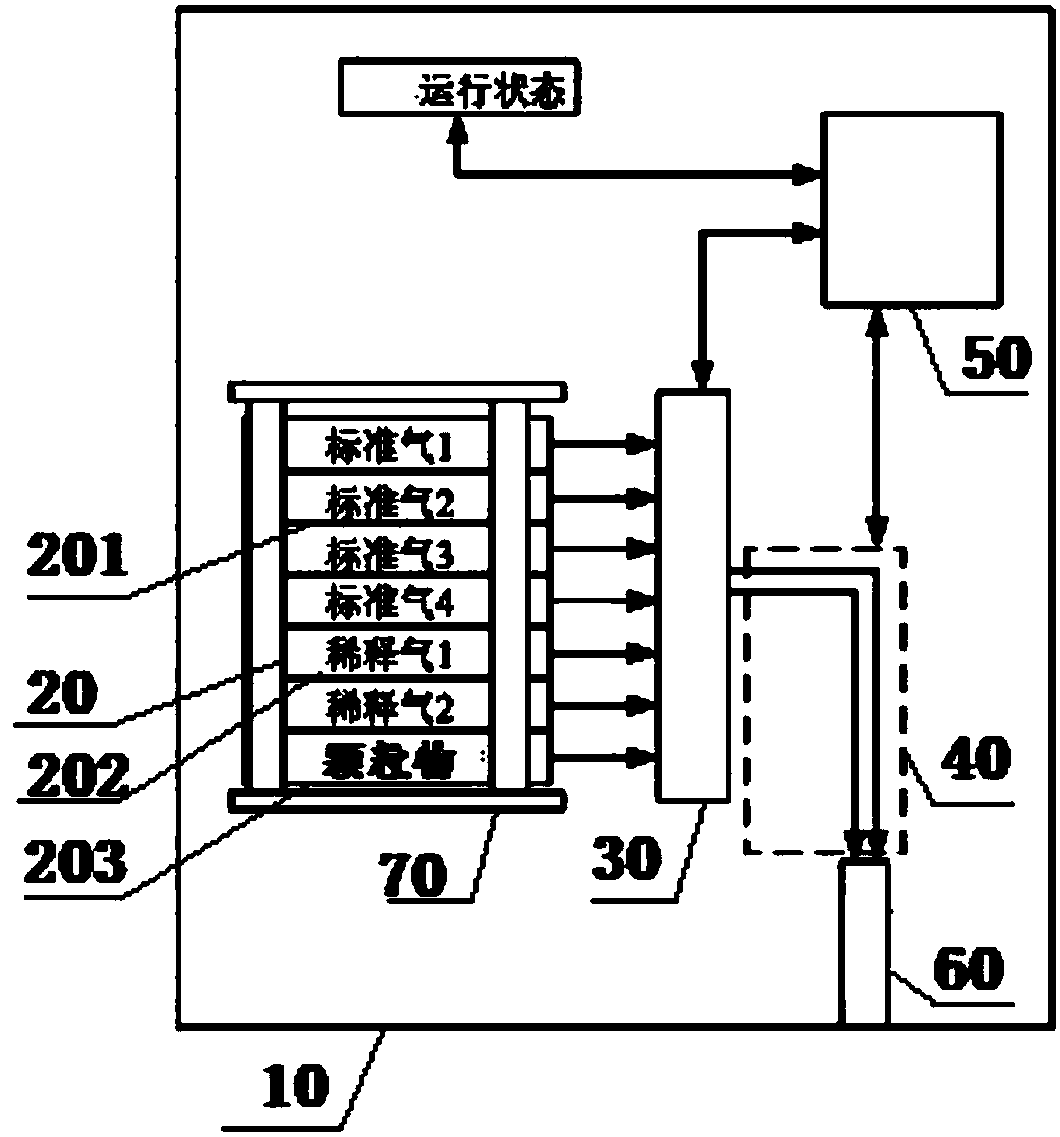

[0053] The basic composition of this embodiment scheme, such as figure 1 As shown: the motion simulation device 10 is realized by a truck, and additionally includes a gas cylinder fixing bracket 70, a standard gas device 201, a dilution gas generator 202, a particulate matter generator 203, a multi-channel mass flow controller 30, and a heating module 40 as a heating pipeline. The air position adjustable device 60 is an exhaust tube, the truck running state recording module, and the system control module 50 is a system control computer.

[0054] The truck is driven by electricity, and its own exhaust pipe should be modified. When performing calibration, calibration, and verifying the motor vehicle exhaust remote measurement system, it can discharge its own exhaust gas to a far distance by switching the switch, which is not good for the standard gas generation system. interfere. The truck itself can run at different speeds, accelerations and trajectories, and can provide compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com