Method for judging lithium-ion-battery cell internal resistance abnormity

A lithium-ion battery and cell technology, which is applied in the measurement of resistance/reactance/impedance, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of increasing the internal resistance monitoring method of the battery cell and scrapping the lithium-ion battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

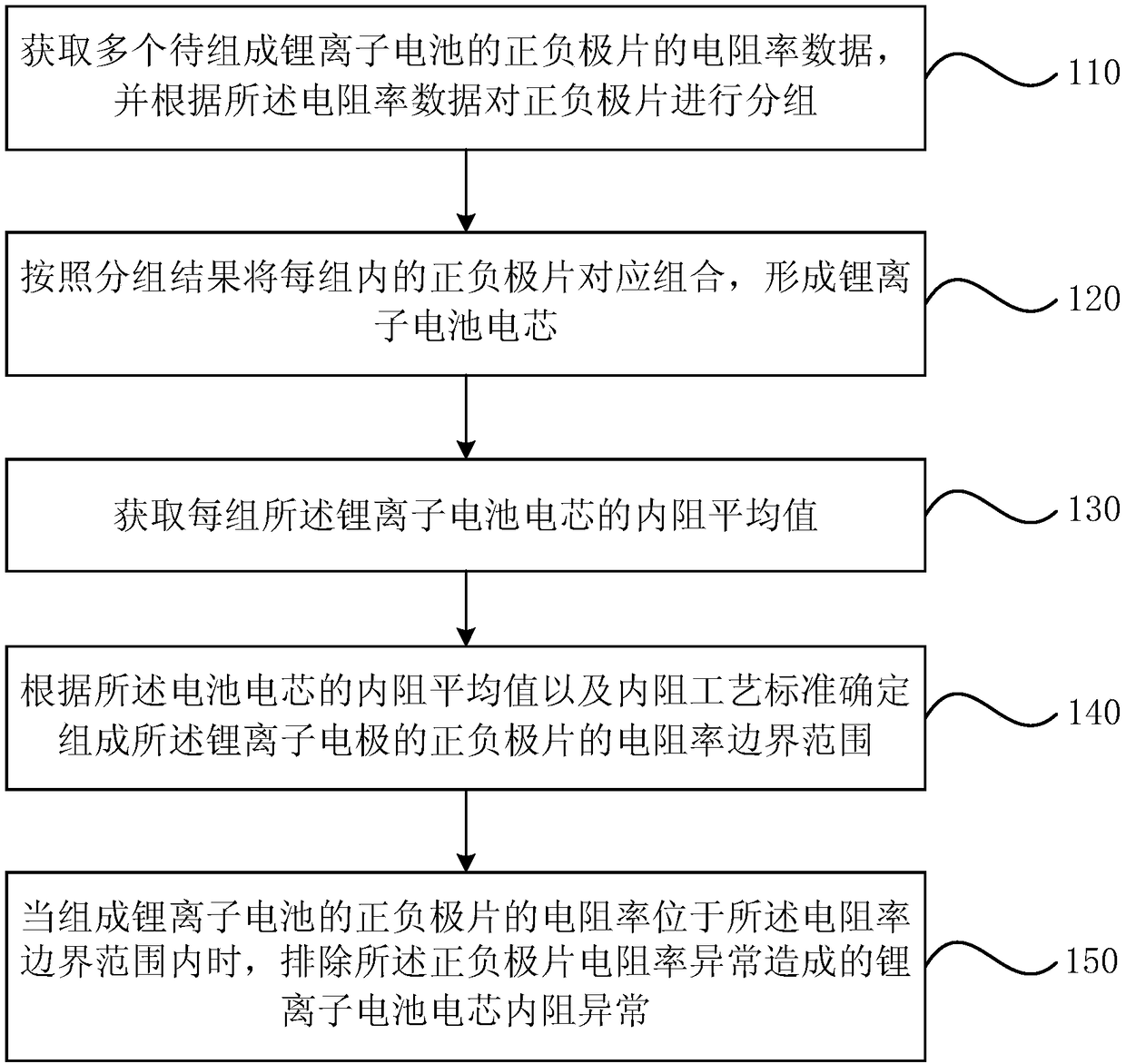

[0043] figure 1 It is a schematic flow chart of a method for judging abnormal internal resistance of a lithium-ion battery cell provided by Embodiment 1 of the present invention. see figure 1 , the method includes:

[0044] S110. Obtain resistivity data of a plurality of positive and negative electrode sheets to be formed into a lithium-ion battery, and group the positive and negative electrode sheets according to the resistivity data.

[0045] Among them, the positive and negative electrodes to be composed of lithium-ion batteries include the positive and negative electrodes that have been stripped and cut into pieces and passed the inspection; the qualified inspection includes the slurry viscosity of the positive and negative electrodes, and the electrodes (unless otherwise specified, " Pole piece" includes both the positive pole piece and the negative pole piece) The surface density of the coating, the cold-pressed thickness of the pole piece, and the rebound thickness of...

Embodiment 2

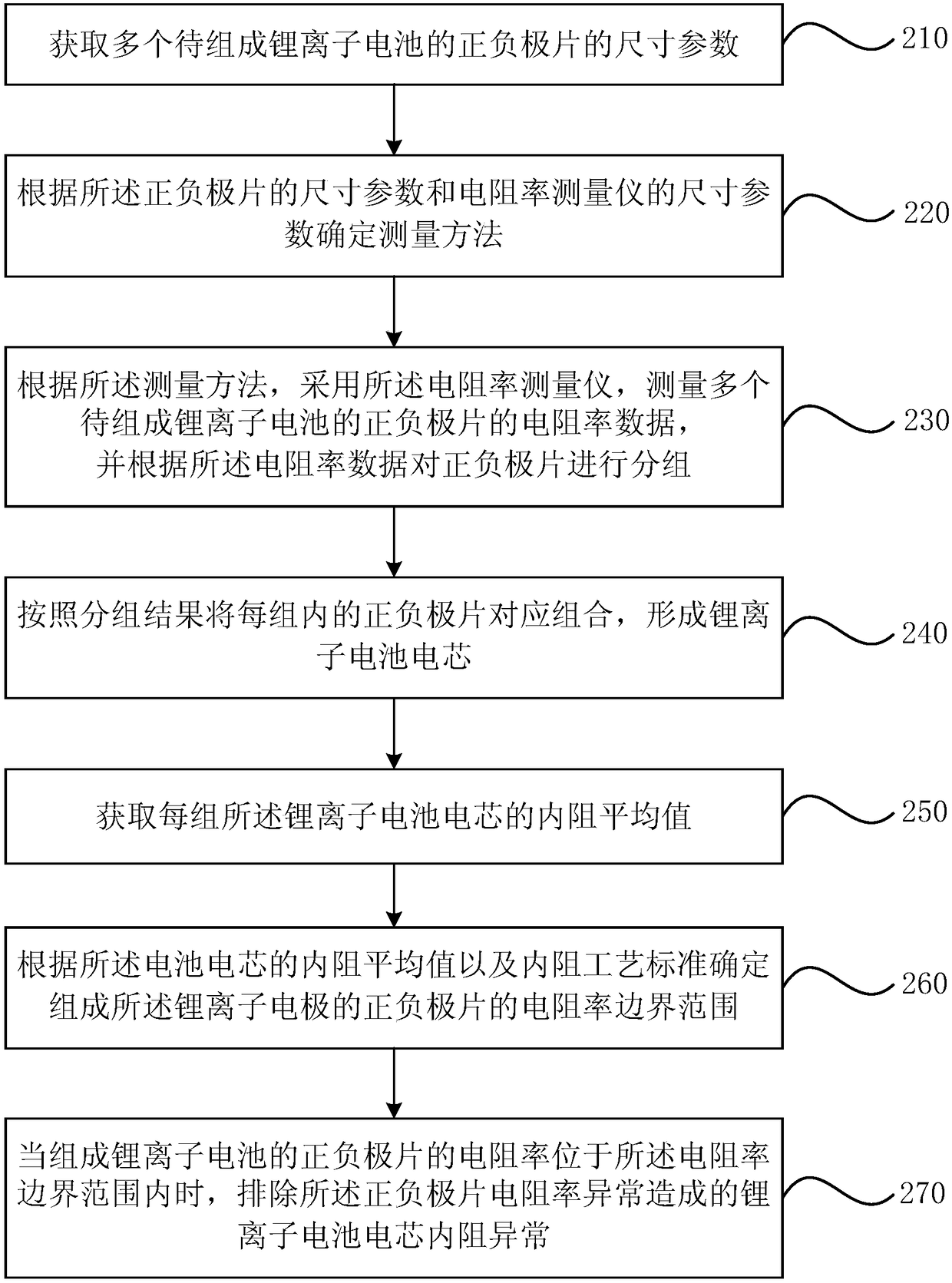

[0075] figure 2 It is a schematic flowchart of a method for judging abnormal internal resistance of a lithium-ion battery cell provided by Embodiment 2 of the present invention. see figure 2 , on the basis of the first embodiment above, the method includes:

[0076] S210. Acquiring size parameters of a plurality of positive and negative electrode sheets to be formed into a lithium-ion battery.

[0077] Wherein, the size parameters of the positive and negative electrodes of the lithium-ion battery include the length, width, boundary area, and effective measurement area of the positive and negative electrodes of the lithium-ion battery. The units of the above dimensions are all length units, which may be millimeters (mm) for example.

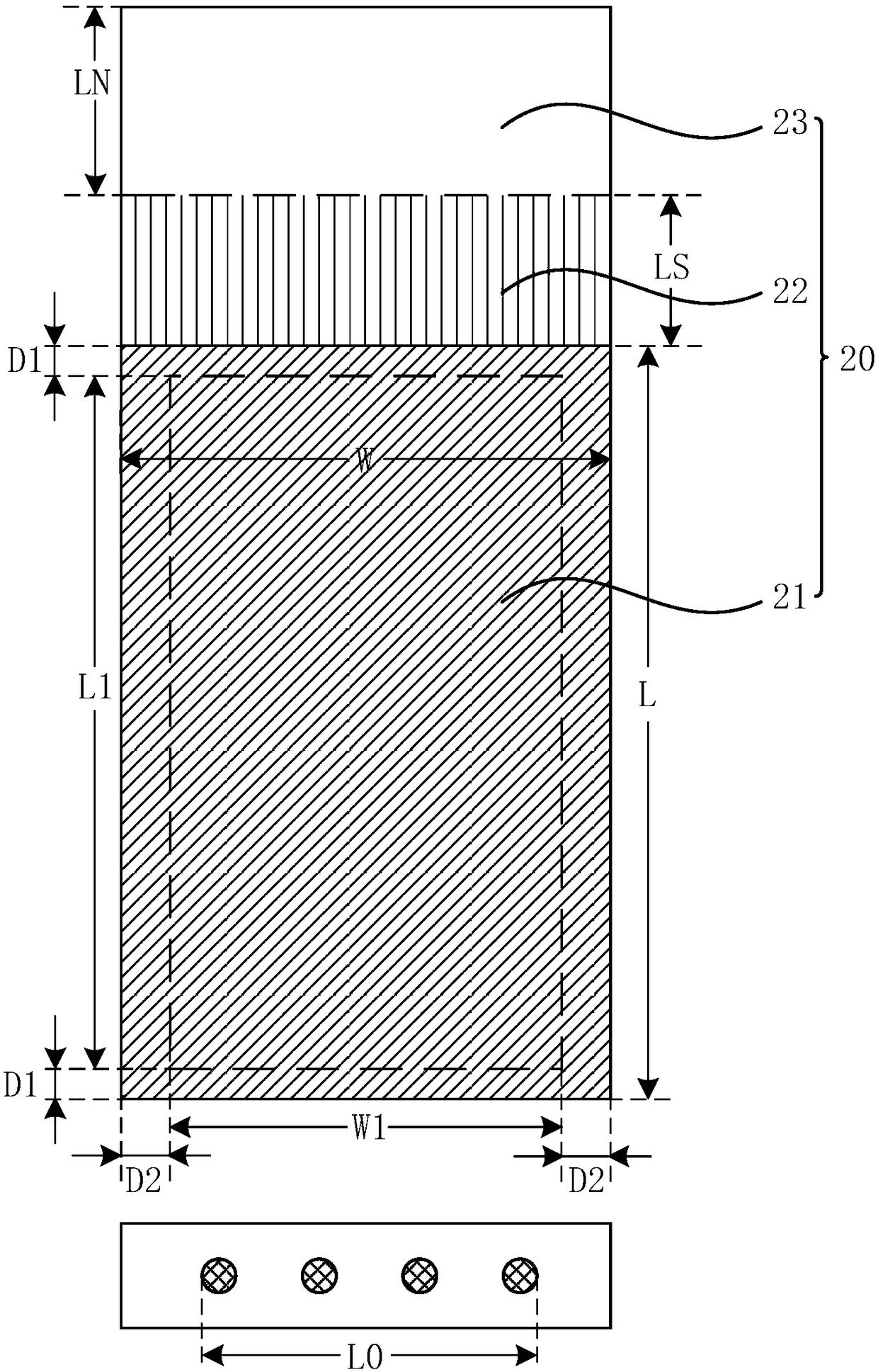

[0078] optional, image 3 It is a schematic diagram of the size parameters of a positive and negative electrode sheet provided in Embodiment 2 of the present invention, Figure 4 It is a schematic diagram of the size parameters of another...

Embodiment 3

[0122] Figure 5 It is a schematic flow chart of a method for judging abnormal internal resistance of a lithium-ion battery cell provided by Embodiment 3 of the present invention. see Figure 5 , on the basis of the first embodiment above, the method includes:

[0123] S310. Obtain the resistivity data of a plurality of positive and negative electrode sheets to be formed into lithium ion batteries, and group the positive and negative electrode sheets by using a two-factor multi-level grouping method according to the resistivity data.

[0124] Wherein, the two factors are positive sheet resistivity and negative sheet resistivity;

[0125] The multiple levels are a plurality of resistivity value intervals evenly divided according to the range of resistivity data of a plurality of positive and negative electrodes of a lithium-ion battery to be formed.

[0126] Wherein, the value range of resistivity can be represented by the median value of the range. Exemplarily, the value ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com