Improved light guide plate

A technology of light guide plate and light guide point, which is applied to the dispersed propagation of geometric optics and the field of light guide plate, which can solve the problems of poor surface roughness of light guide plate, uneven light output from light guide plate, and inability to cut the finished product at will, so as to shorten the production cycle , high luminous efficiency, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

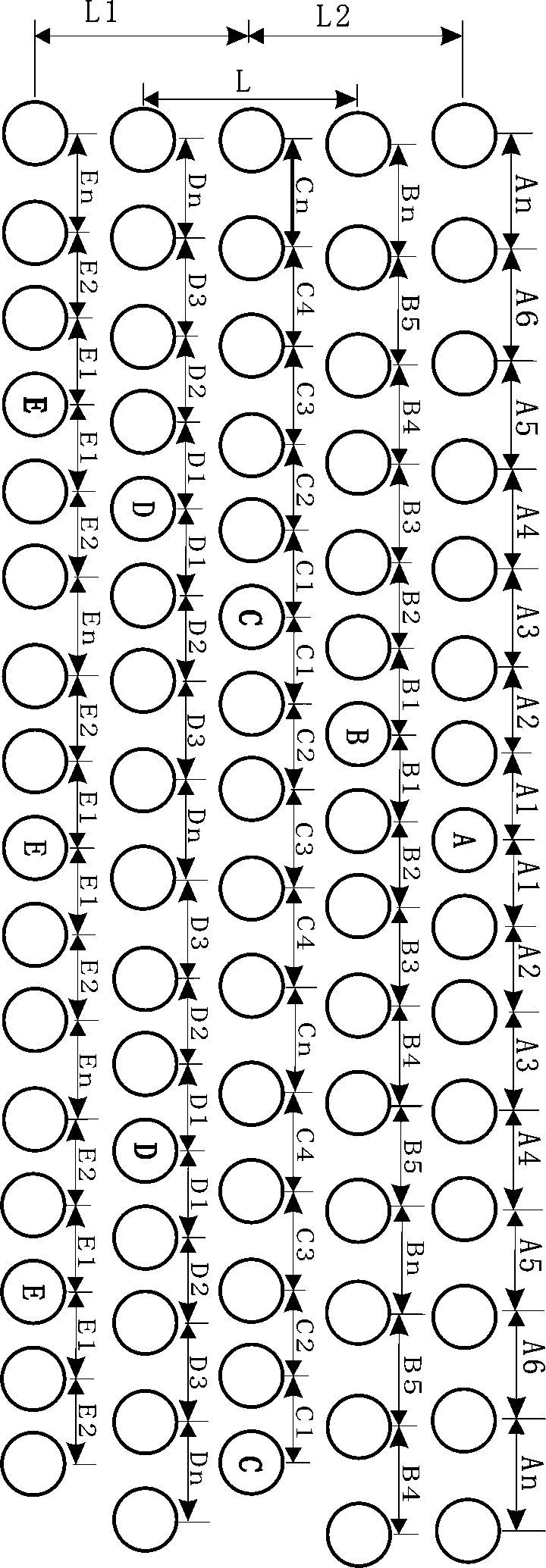

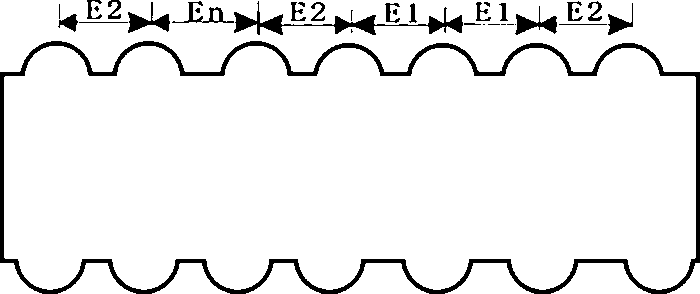

[0025] Implement 1, such as Figure 1-2 As shown, the front and back sides of the light guide plate are composed of two groups of asymmetric convex-sphere-shaped light guide points, and the two groups change according to the following rules:

[0026] The light guide points are arranged in five groups of ABCDE to form a small unit. The group E takes the light guide point E as the middle light guide point, and the distance between the light guide points on both sides of the light guide point E is larger than the other E1<E2<En, After reaching the distance En, they are reversely arranged from En to E1, and the circular arrangement is repeated in this way. Similarly, each group of BCDE uses the light guide point BCDE as the intermediate light guide point and repeats the circular arrangement in this way; The distance between the two light guide points of the sequence number is equal, that is, E1=D1=C1=B1=A1, E2=D2=C2=B2=B2, and the number of light guide points in each group of ligh...

Embodiment 2

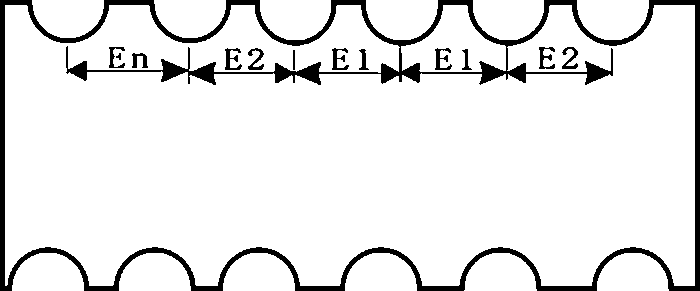

[0028] Implement 2, such as figure 1 , 3 As shown, the front and back sides of the light guide plate are composed of two groups of asymmetric concave spherical light guide points, and the two groups change according to the following rules:

[0029] The light guide points are arranged in five groups of ABCDE to form a small unit. The group E takes the light guide point E as the middle light guide point, and the distance between the light guide points on both sides of the light guide point E is larger than the other E1<E2<En, After reaching the distance En, they are reversely arranged from En to E1, and the circular arrangement is repeated in this way. Similarly, each group of BCDE uses the light guide point BCDE as the intermediate light guide point and repeats the circular arrangement in this way; The distance between the two light guide points of the sequence number is equal, that is, E1=D1=C1=B1=A1, E2=D2=C2=B2=B2, and the number of light guide points in each group of light...

Embodiment 3

[0031] Implementation 3, implementation 2, such as figure 1 , 4 As shown, the front side of the light guide plate is a group of convex-spherical-shaped light-guiding points, and the back is a group of concave-spherical-shaped light-guiding points, and the two groups change according to the following rules:

[0032] The light guide points are arranged in five groups of ABCDE to form a small unit. The group E takes the light guide point E as the middle light guide point, and the distance between the light guide points on both sides of the light guide point E is larger than the other E1<E2<En, After reaching the distance En, they are reversely arranged from En to E1, and the circular arrangement is repeated in this way. Similarly, each group of BCDE uses the light guide point BCDE as the intermediate light guide point and repeats the circular arrangement in this way; The distance between the two light guide points of the sequence number is equal, that is, E1=D1=C1=B1=A1, E2=D2=C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com