Thin-film AlGaInP light-emitting diode chip and its preparation method

A light-emitting diode, thin-film technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of light extraction efficiency of less than 10%, and achieve the effect of improving electro-optical conversion efficiency, improving identification, and reducing shading effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

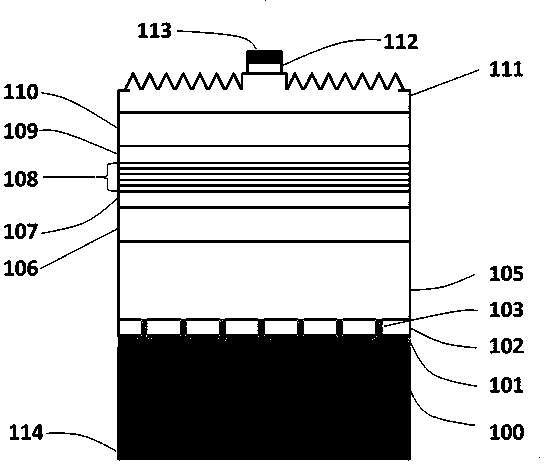

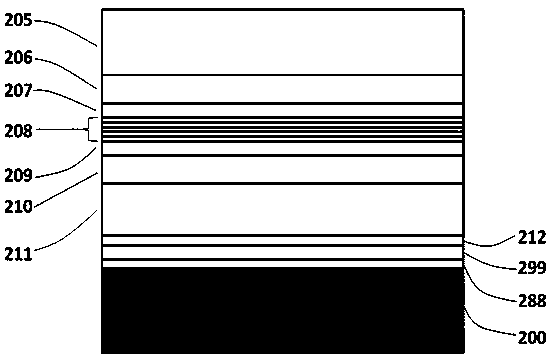

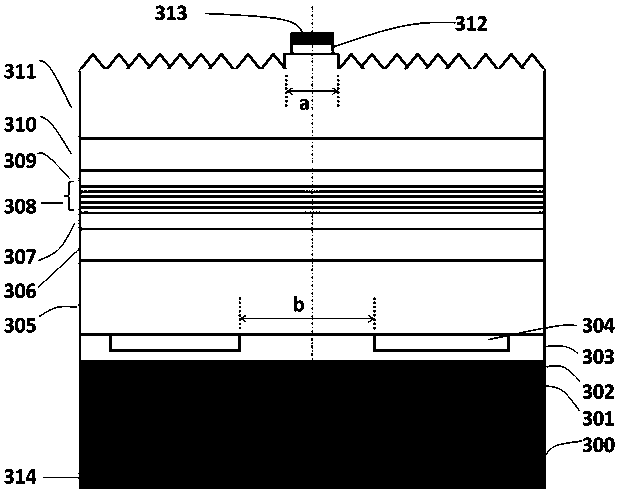

[0037] image 3 As shown, a thin-film AlGaInP light-emitting diode chip includes: a bonding substrate 300 with front and back sides; from the front of the bonding substrate 300 upwards are: substrate side metal bonding layer 301, epitaxial material side metal bonding layer 302, the P-surface diffusion barrier metal layer 303 and the P-surface reflective ohmic contact layer 304, the P-surface reflective ohmic contact layer 304 is an Ag or Ni / Ag laminated structure, and forms a good ohmic contact with the P-type current spreading layer 305, and has Light reflection and ohmic contact function; from the P surface reflection ohmic contact layer 304, there are P-type current spreading layer 305, P-type confinement layer 306, P-side space layer 307, multi-quantum well light-emitting region 308, N-side space layer 309, N-type confinement layer 310 , N-type r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| internal quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com