Thermal insulation material

A heat insulation and protective layer technology, applied in the direction of heat preservation, pipeline protection through heat insulation, pipeline protection, etc., can solve environmental hazards, adverse effects on human health, isolation of ultraviolet rays, heat reflection, moisture resistance, and radiation protection can not meet the needs of use And other problems, to achieve strong barrier, easy to transport and construction, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

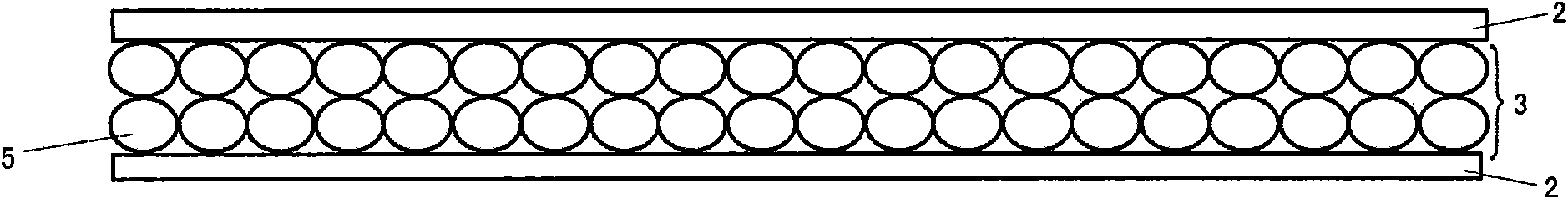

[0025] figure 1 Show the heat insulation material of embodiment 1, this material comprises a) polyethylene bubble layer 3, it comprises two layers of polyethylene bubbles 5, and the height of described polyethylene bubble is 2.5mm, and diameter is 8mm; And b) aluminum foil Layer 2, the aluminum foil layer 2 is arranged on both sides of the polyethylene air bubble layer 3 .

Embodiment 2

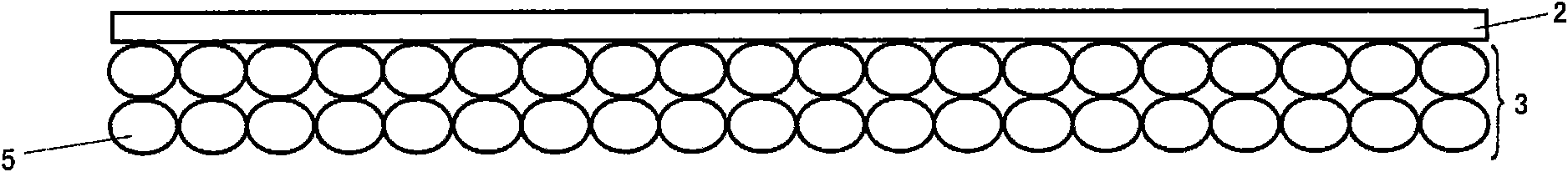

[0027] figure 2 Shown is the thermal insulation material of embodiment 2, and this material comprises a) polyethylene bubble layer 3, and it comprises two layers of polyethylene bubbles 5, and the diameter of described polyethylene bubble 5 is 8mm, and height is 9mm; And b) The aluminum foil layer 2 is arranged on one side of the polyethylene air bubble layer 3 .

Embodiment 3

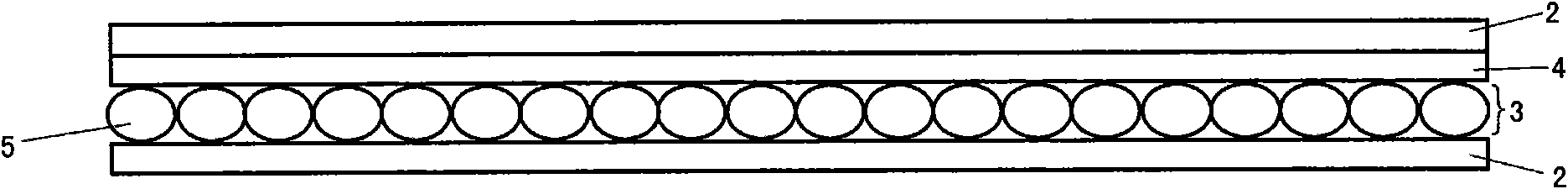

[0029] image 3 Shown is the thermal insulation material of embodiment 3, and this material comprises a) polyethylene bubble layer 3, and it comprises one deck polyethylene bubble 5, and the diameter of described polyethylene bubble 5 is 10mm, and height is 15mm; And b) Aluminum foil layer 2, described aluminum foil layer 2 is arranged on the both sides of polyethylene bubble layer 3, and C) woven cloth layer or glass fiber layer 4, described woven cloth layer or glass fiber layer 4 are arranged on aluminum foil layer 2 and polyethylene Between layers of air bubbles 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com