Combined lithium ion battery assembly line and application method thereof

A lithium-ion battery, combined technology, applied in the direction of non-aqueous electrolyte storage battery, electrolyte storage battery manufacturing, final product manufacturing, etc., can solve the problems of unfavorable utilization and influence of product development resources, achieve strong adjustment of process production, and wide application range , The effect of increasing the utilization rate of production resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

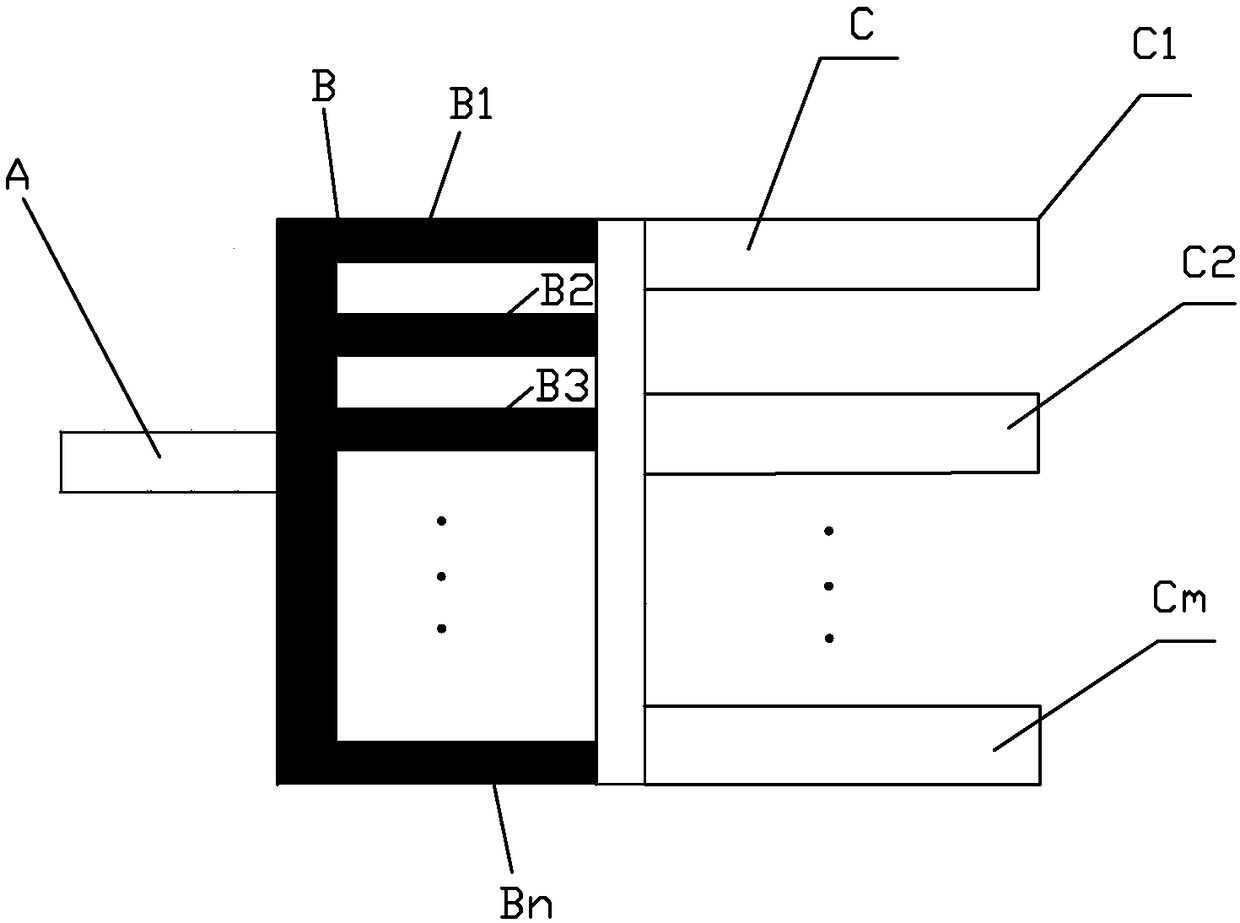

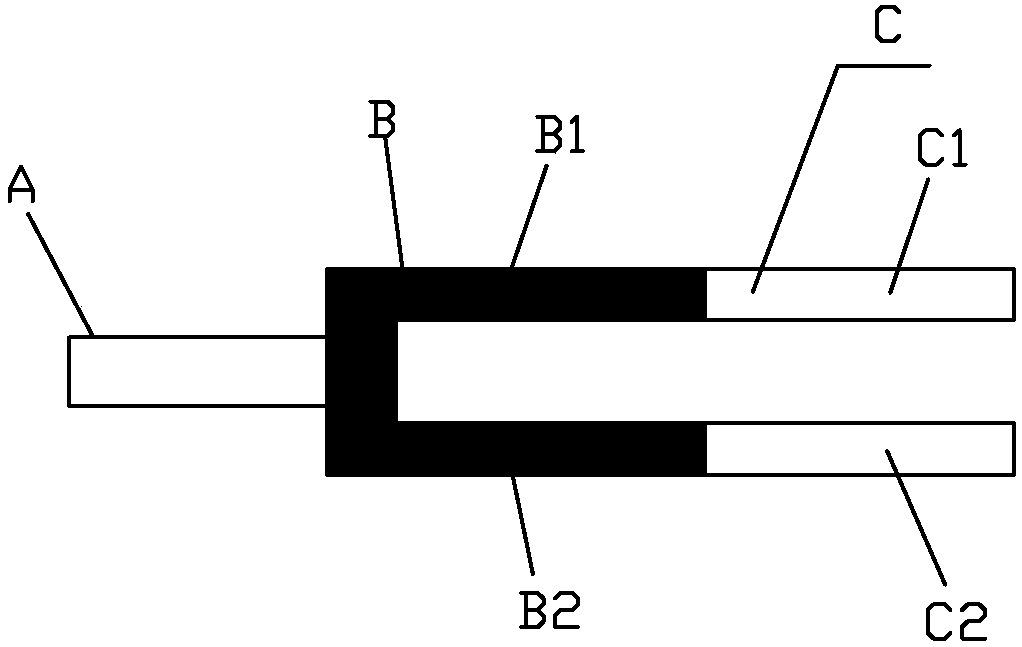

[0050] Such as figure 2 As shown, as a preferred multi-process combined production line, it includes a battery pole piece manufacturing device A, a battery assembly device group B, and a liquid injection and storage device group C. The battery pole piece manufacturing device A, the battery assembly device group B, and the liquid injection and storage device group C are connected in sequence. The battery assembly device group B includes a battery assembly device B1 and a battery assembly device B2, and the battery assembly devices B1 and B2 are arranged side by side. The battery assembly device B1 is a stack assembly section (battery stack assembly device), and the battery assembly device B2 is a winding assembly section (battery winding assembly device). C1 and C2 are liquid injection and chemical composition container devices. The battery pole piece manufacturing device A and the battery assembly device group B are connected by a conveying mechanism including a roller trac...

Embodiment 2

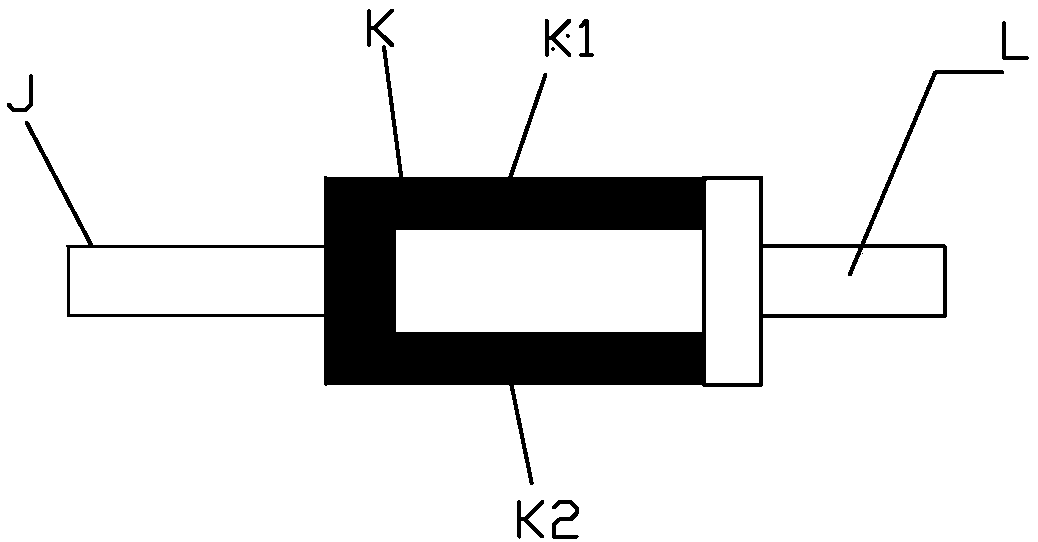

[0053] Such as image 3 As shown, the first-line production line of various cylindrical battery products includes battery pole piece manufacturing device J, battery assembly device group K, and liquid injection and storage device group L. The battery pole piece manufacturing device J, the battery assembly device group K, and the liquid injection and storage device L are connected in sequence. The battery assembly device group K includes the battery model 18650 assembly section K1 (battery assembly device K1) for the winding assembly process and the battery model 21700 assembly section K2 (battery assembly device K2) for the winding assembly process, and the battery assembly sections K1 and K2 are juxtaposed arrangement. The battery pole piece manufacturing device J and the battery assembly device segment K are connected through a conveying mechanism including a belt conveyor. The battery assembly sections K1 and K2 are jointly connected to the liquid injection and chemical c...

Embodiment 3

[0056] Such as Figure 4 As shown, a multi-product production line includes a battery pole piece manufacturing device 1, a battery assembly device group 2, and a liquid injection and storage device group 3. The battery pole piece manufacturing device 1, the battery assembly device group 2, and the liquid injection and storage device group 3 are connected in sequence. The battery assembly device group 2 includes a square battery assembly section 21 (battery assembly device 21), a pouch battery assembly section 22 (battery assembly device 22), a cylindrical battery assembly section 23 (battery assembly device 23); a square battery assembly section 21, The pouch battery assembly section 22 and the cylindrical battery assembly section 23 are arranged side by side. The battery pole piece manufacturing device 1 and the battery assembly device group 2 are equipped with slide rails on the ground to switch between different slide rails and connect to different battery assembly section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com