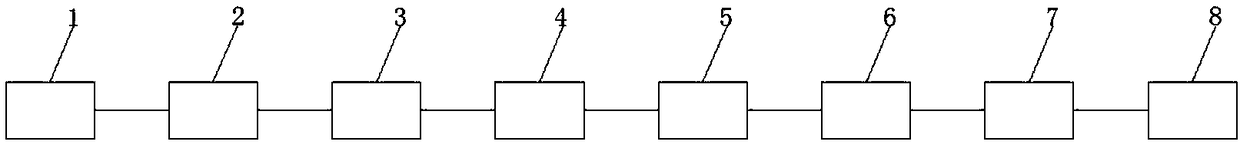

Production line of traditional fish noodles

A production line, fish noodle technology, applied in the direction of dough mixer, dough extruder, structural components of mixing/kneading machinery, etc., can solve the problems of insufficient stability, inability to adjust strength, easy waste of raw materials, etc., and achieve reasonable structural design. , improve efficiency and avoid waste effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

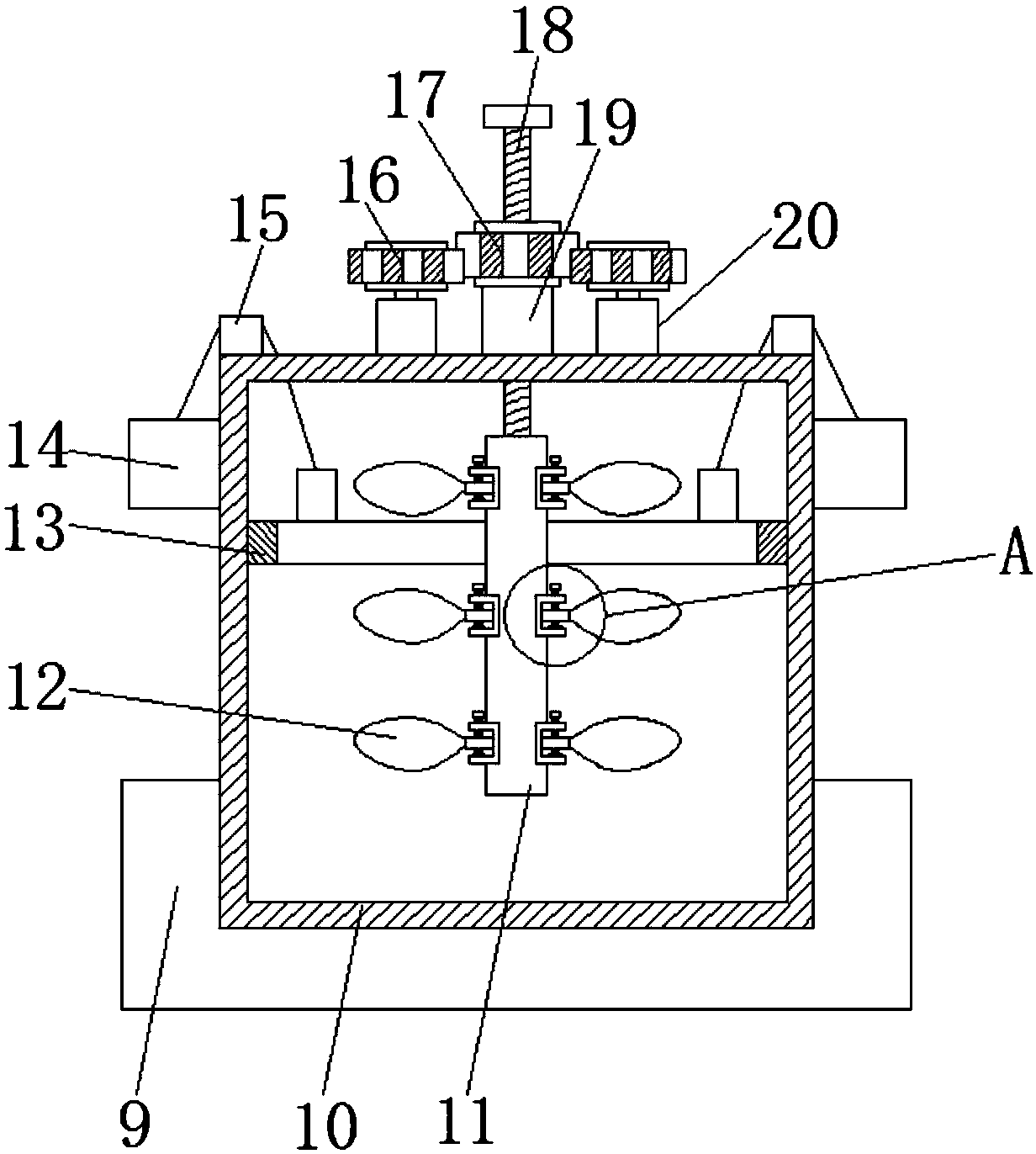

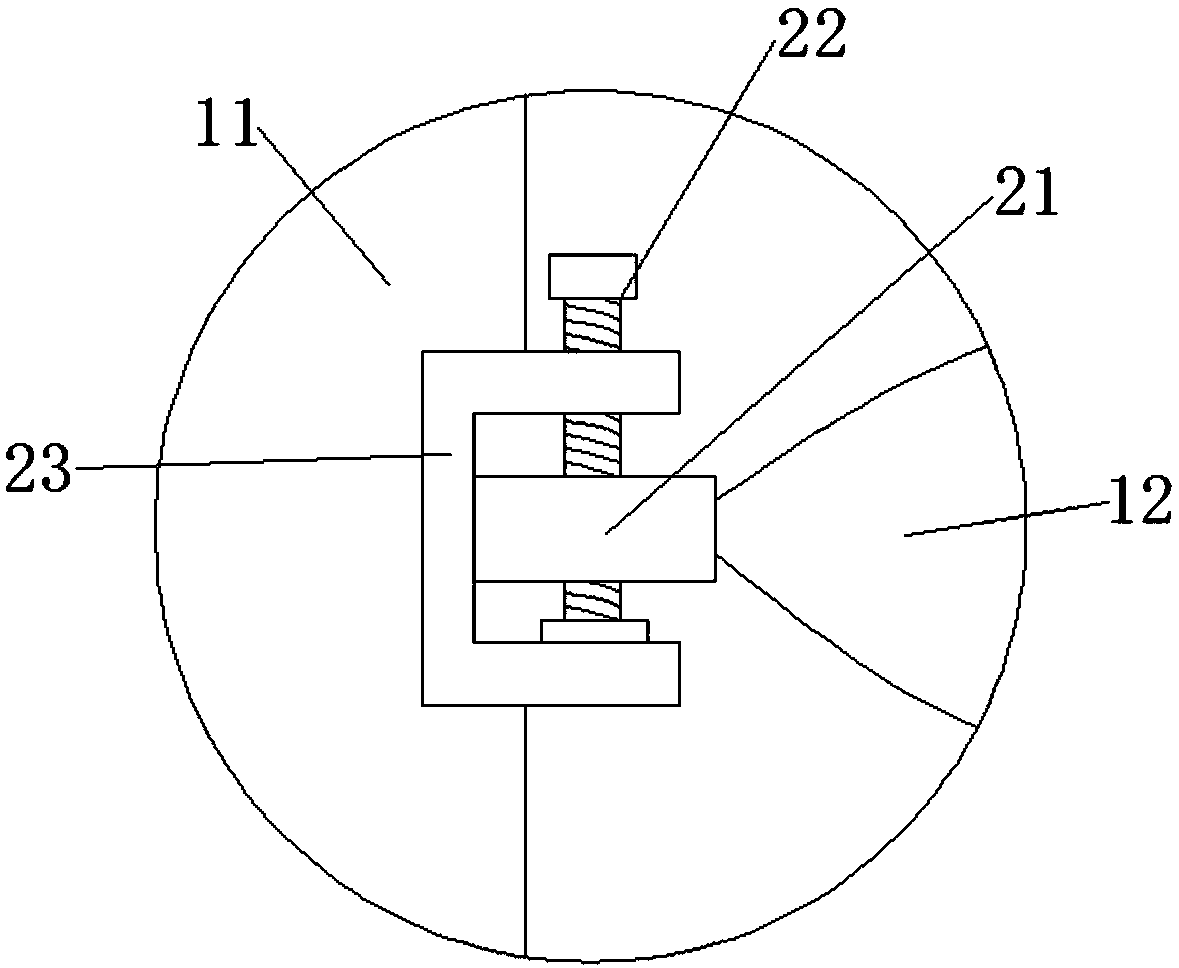

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0021] refer to Figure 1-5, a traditional fish noodle production line, comprising metering equipment 1, noodle mixing equipment 2, aging equipment 3, calendering equipment 4, strip cutting equipment 5, drying equipment 6, cutting equipment 7 and packaging equipment 8, and noodle mixing equipment 2 arranged in sequence Including the first base 9, the upper end of the first base 9 is provided with a first limiting groove, the inner bottom of the first limiting groove is fixedly connected with a first housing 10, and the inside of the first housing 10 is provided with a stirring chamber Two first servo motors 20 are symmetrically arranged on the upper end side wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com