Environment-friendly efficient fire extinguishing agent and preparing method thereof

A fire extinguishing agent and high-efficiency technology, which can be used in fire prevention equipment and other directions, can solve the problems of large environmental pollution, environmental pollution, poor fire extinguishing effect, etc., and achieve the effect of improving fire extinguishing performance, uniform distribution, and easy foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

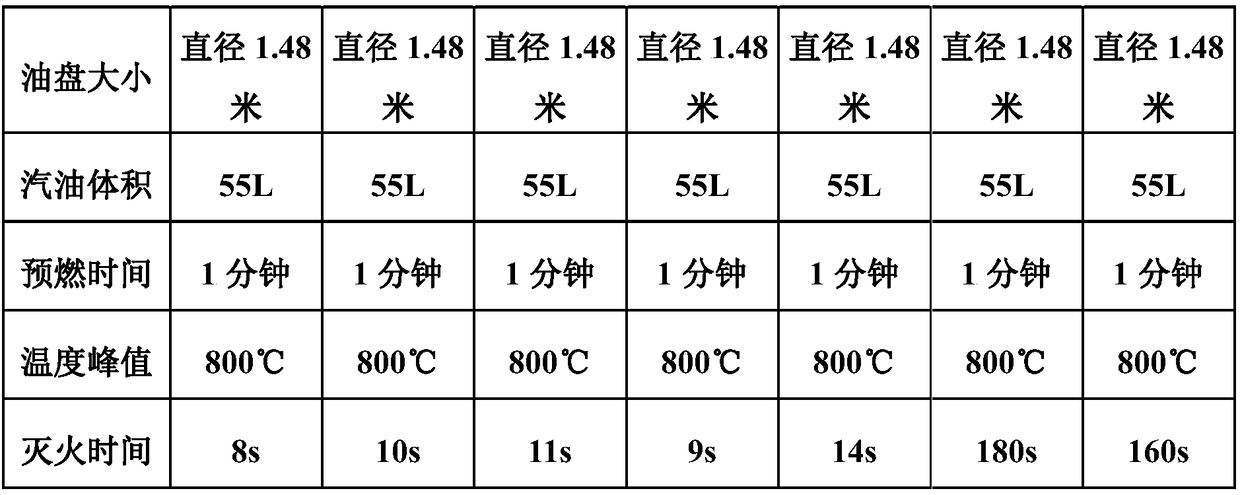

Examples

preparation example Construction

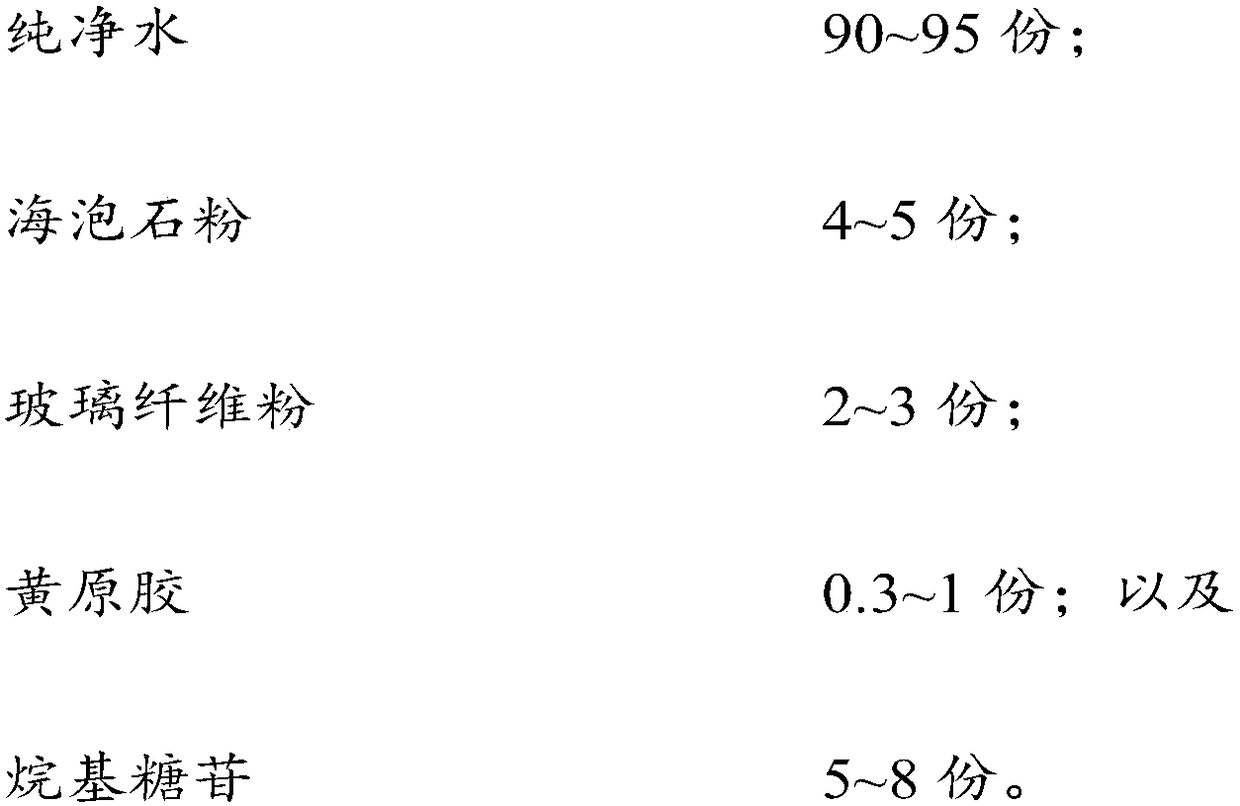

[0033] The preparation method of the above-mentioned environment-friendly high-efficiency fire extinguishing agent provided by the embodiment of the present invention comprises: adding glass fiber powder and alkyl glucoside into purified water, stirring and mixing at 25-35°C for 10-15 minutes, and the stirring rate is 80-100r / min, to obtain first mixture. Add xanthan gum to the first mixed solution, stir and mix at 35-40° C. for 7-10 minutes at a stirring rate of 100-120 r / min to obtain the second mixed solution. Add sepiolite powder into the second mixed liquid, stir and mix at 35-40°C for 7-10 minutes, and the stirring rate is 100-120 r / min to obtain an environmentally friendly and efficient fire extinguishing agent.

[0034] The preparation method of the above-mentioned environmentally friendly and efficient fire extinguishing agent provided by the embodiment of the present invention first stirs and mixes the glass fiber powder and the alkyl glucoside in pure water, on the ...

Embodiment 1

[0041] This embodiment provides an environmentally friendly and efficient fire extinguishing agent.

[0042] The raw materials include 90 parts by weight of purified water, 4.5 parts of sepiolite powder, 2.5 parts of glass fiber powder, 0.5 part of xanthan gum and 7 parts of alkyl glycoside. Among them, the particle size of the sepiolite powder is -80 mesh to +100 mesh, and the particle size of the glass fiber powder is -200 mesh to +230 mesh.

[0043] It is prepared by the following method:

[0044] Add glass fiber powder and alkyl glucoside to purified water, stir and mix at 30° C. for 12 minutes at a stirring rate of 100 r / min to obtain the first mixed solution. Add xanthan gum to the first mixed solution, stir and mix at 40° C. for 10 min at a stirring rate of 120 r / min to obtain the second mixed solution. Add sepiolite powder to the second mixed solution, stir and mix at 40°C for 10 minutes, and the stirring rate is 120r / min, to obtain an environmentally friendly and ef...

Embodiment 2

[0046] This embodiment provides an environmentally friendly and efficient fire extinguishing agent.

[0047] The raw materials include 95 parts by weight of purified water, 4 parts of sepiolite powder, 3 parts of glass fiber powder, 1 part of xanthan gum and 6 parts of alkyl glycoside. Among them, the particle size of the sepiolite powder is -100 mesh to +120 mesh, and the particle size of the glass fiber powder is -170 mesh to +200 mesh.

[0048] It is prepared by the following method:

[0049] Add glass fiber powder and alkyl glucoside to purified water, stir and mix at 35° C. for 15 minutes at a stirring rate of 90 r / min to obtain the first mixed solution. Add xanthan gum to the first mixed solution, stir and mix at 35° C. for 7 minutes at a stirring rate of 100 r / min to obtain the second mixed solution. Add sepiolite powder to the second mixed solution, stir and mix at 35°C for 7 minutes, and the stirring rate is 120r / min, to obtain an environmentally friendly and effici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com