Nozzle forging method and nuclear power main pump casing copy forging process

A technology for nozzles and cylinders, which is applied in the field of nozzle forging methods and nuclear power main pump casing profiling forging technology, can solve the problems of low material utilization rate of forgings, low material utilization rate, and large forging weight, and achieve the reduction of material Cost, forging weight reduction, and manufacturing cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

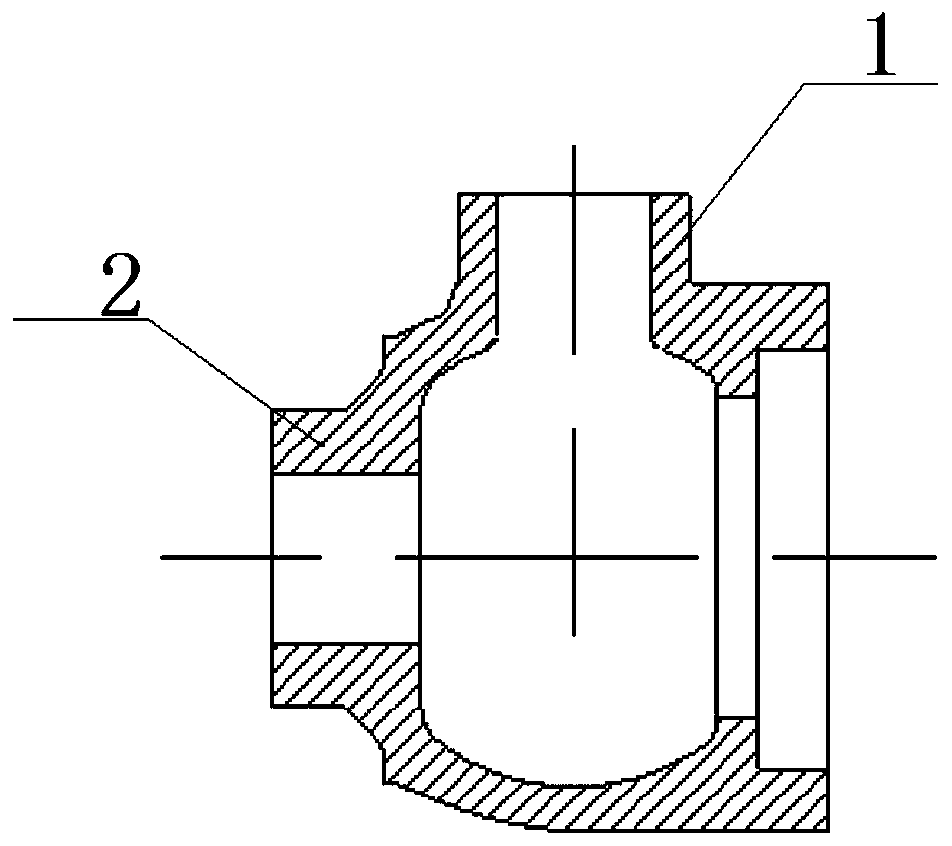

[0042] The present invention will be further described by taking the profiling forging of the pump casing forging of the nuclear power main pump as an example below.

[0043] The main steps of the profiling forging process for pump casing forgings of nuclear power main pumps are as follows:

[0044] ①Steel ingot pressing jaw, after the steel ingot is heated, the riser presses the jaw, which is convenient for the clamping operation of the next upsetting process;

[0045] ②Upsetting and blanking, upsetting and drawing the billet to lengthen the billet to improve the structural defects of the steel ingot;

[0046] ③ Upsetting and punching, after blanking, upsetting and punching the billet to make a billet for hole expansion;

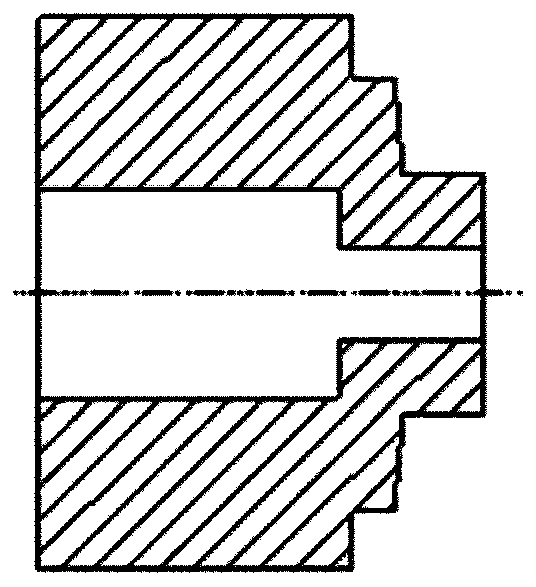

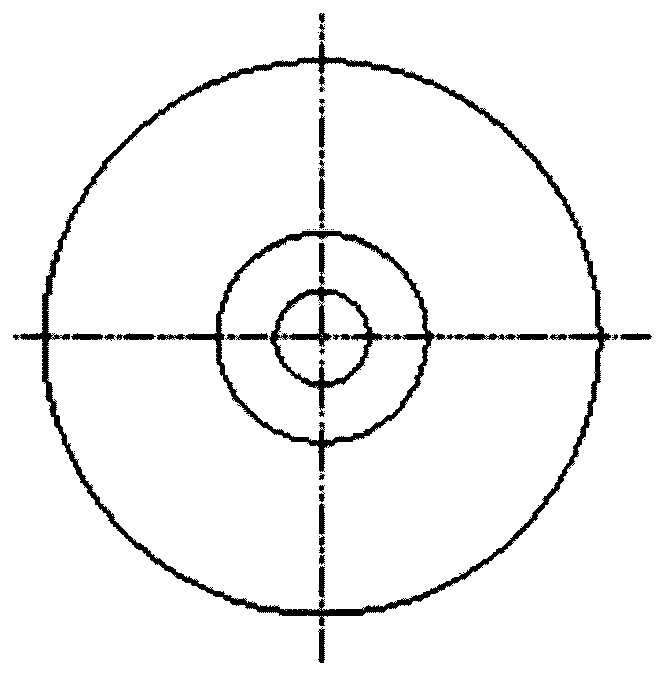

[0047] ④ The horse bar is reamed, the horse bar is reamed until the diameter meets the size of the intermediate blank, and the intermediate blank is made, and the intermediate blank is the cylinder blank 9;

[0048] ⑤ Process a positioning hole on the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com