Auxiliary device for manually welding components

An auxiliary device, manual welding technology, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve problems such as increasing welding height, and achieve the effect of simplifying alignment, reducing manual operation, and preventing device installation from tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Describe the present invention below in conjunction with specific embodiment:

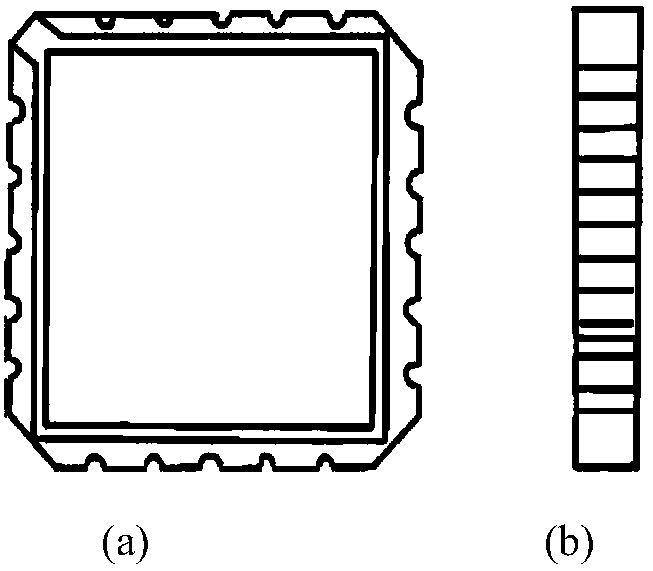

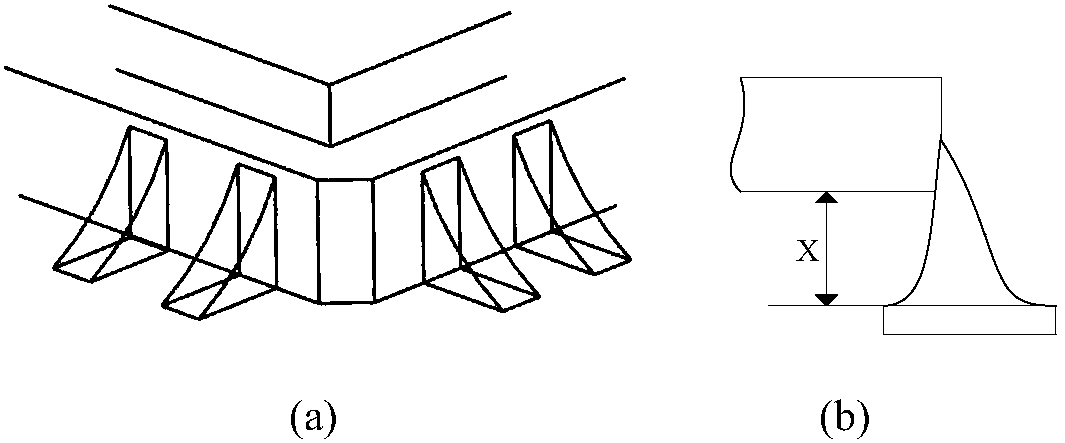

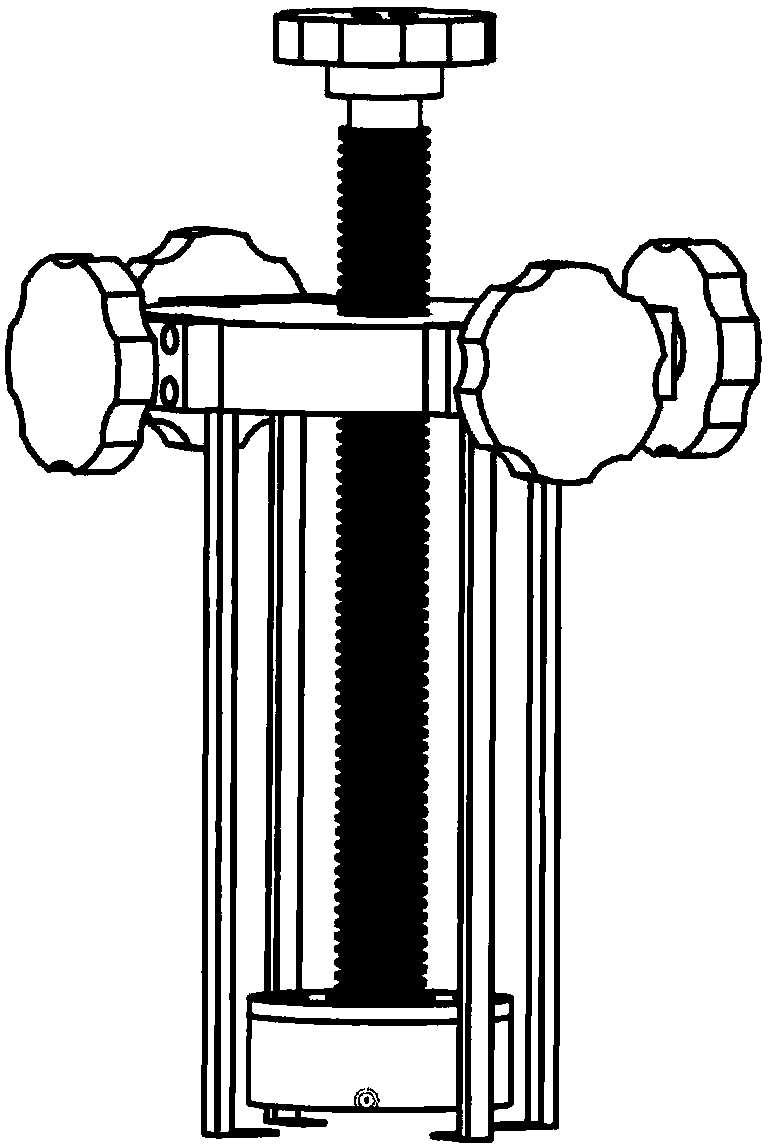

[0043] The invention discloses an auxiliary device for manually soldering packaging components with pins around the center and no pads in the center, such as image 3 shown. The device is composed of pressing components and clamping components, such as Figure 4 shown.

[0044] The compression assembly is composed of height adjustment handwheel, compression screw, bearing, bearing outer ring fixing plate and compression seat. The general structure diagram of the compression assembly is as follows: Figure 5 As shown, the height adjustment handwheel, compression screw, bearing outer ring fixed pressure plate and compression seat are as follows Figure 6 , 7 , 8, and 9. The lower end of the screw rod passes through the inner ring of the bearing (rotating part), and the outer ring of the bearing is fastened through the pressing plate and the pressing seat, and the pressing plate and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com