Driving device for linear movement, pickup device unit and transfer operation equipment

A driving device, linear motion technology, applied in the direction of transmission, mechanical equipment, transportation and packaging, etc., can solve problems such as expansion of backlash, reduction of service life, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make your review committee members have a further understanding of the present invention, the preferred embodiments are hereby given in conjunction with the drawings, and are described in detail as follows:

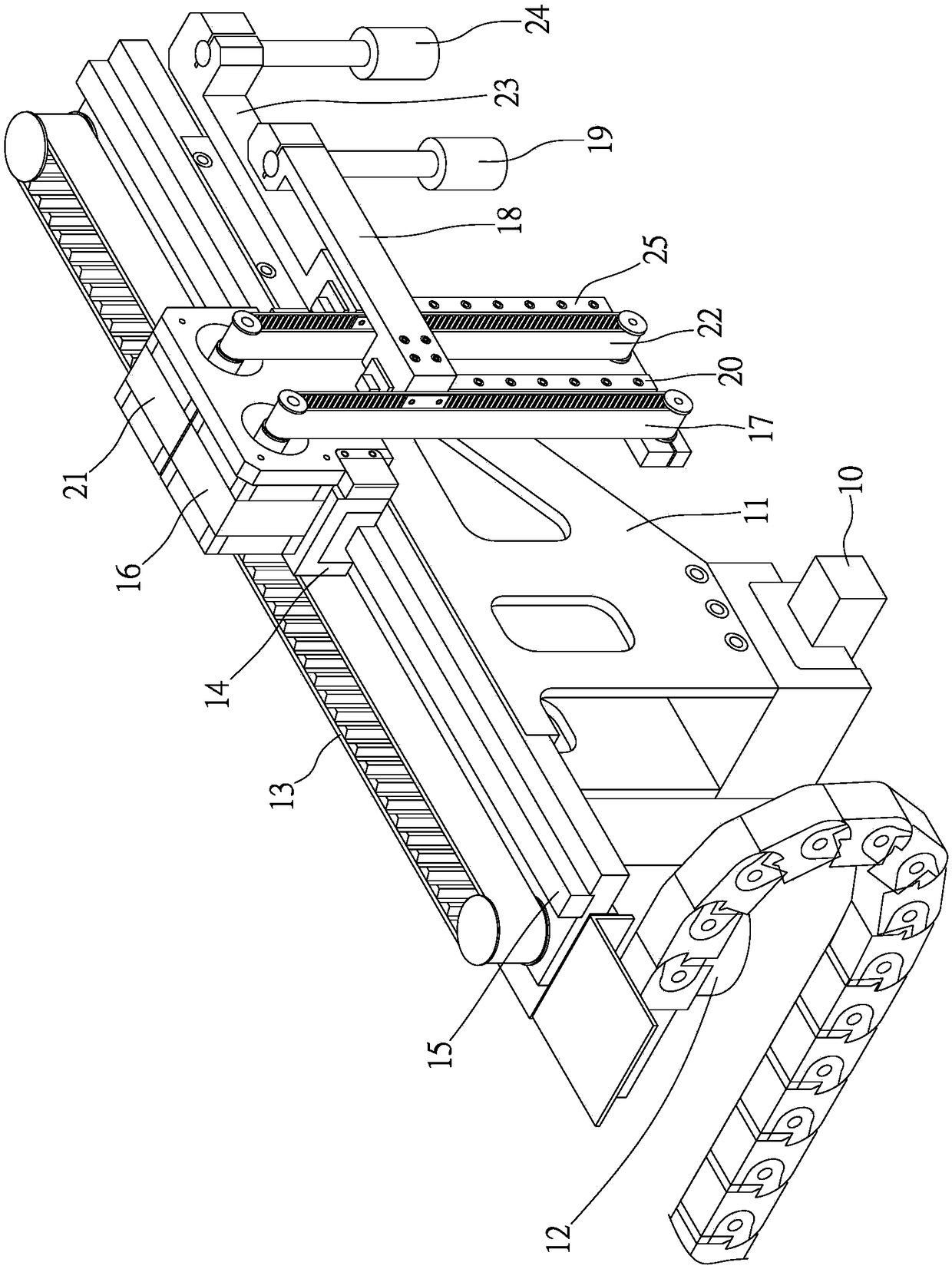

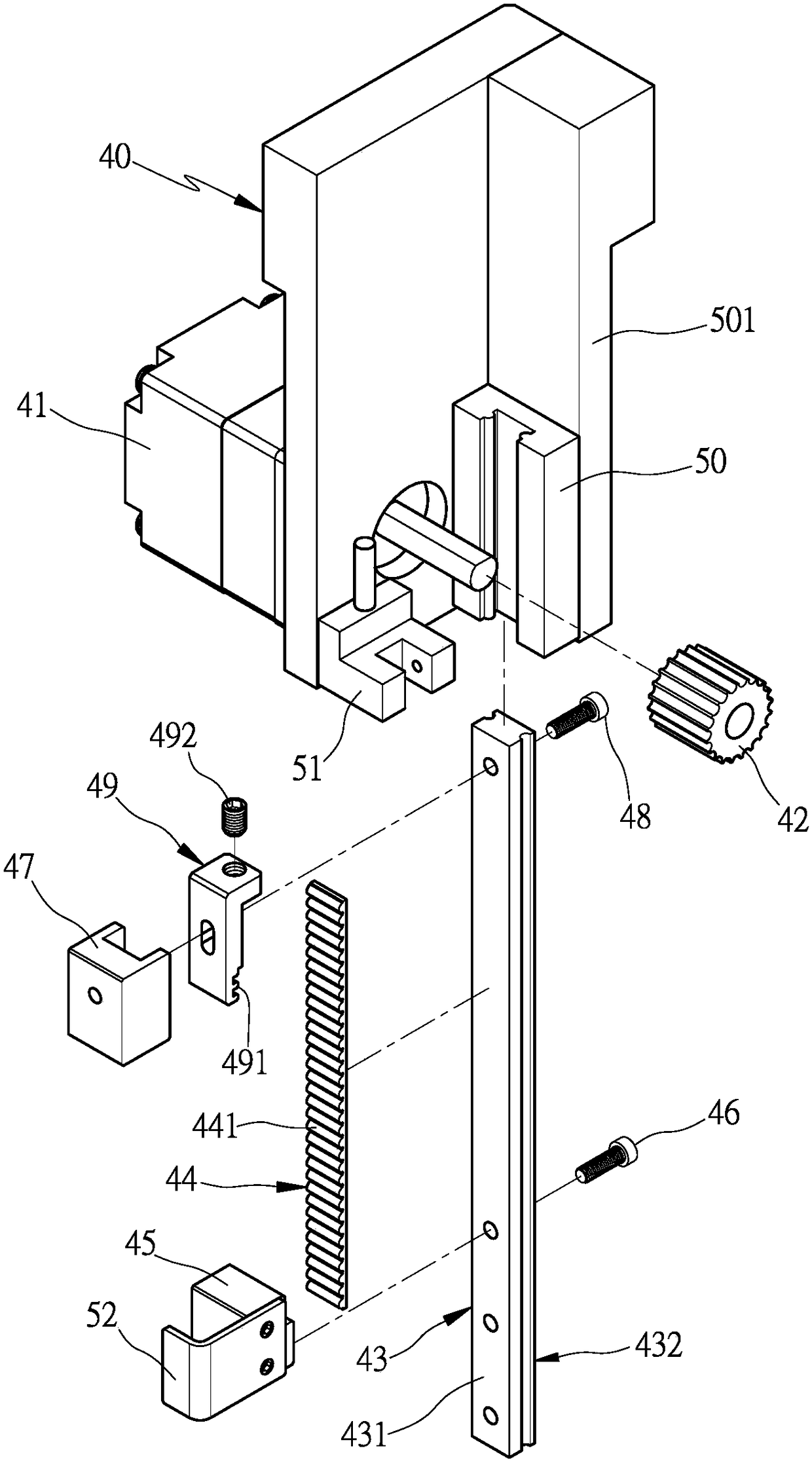

[0057] see image 3 , Figure 4 , Figure 5 The driving device for linear motion of the present invention is to mount a driving source 41 on a base 40, and the driving source 41 is connected with a transmission gear 42, so that the driving source 41 can drive the transmission gear 42 to rotate when actuated. In this embodiment, the driving source 41 is a servo motor, and a transmission gear 42 is connected to the output shaft end; a pair of placement parts 43 is provided with a first surface side 431 at a tooth surface position relative to the transmission gear 42, On the other side opposite to the first surface side 431, a second surface side 432 is provided, and the opposing member 43 is provided with a strip-shaped linear toothed belt 44 meshing wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com