Activating agent for water transfer printing

A technology of water transfer printing and activator, applied in printing, copying/marking methods, etc., can solve the problems affecting the yield of water transfer printing workpieces, high content of organic volatiles, unclear white dot patterns, etc., to achieve unclear patterns Low, less aromatic compounds, good water transfer printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment illustrates the water transfer printing activator provided by the present invention and the method for using the water transfer printing activator.

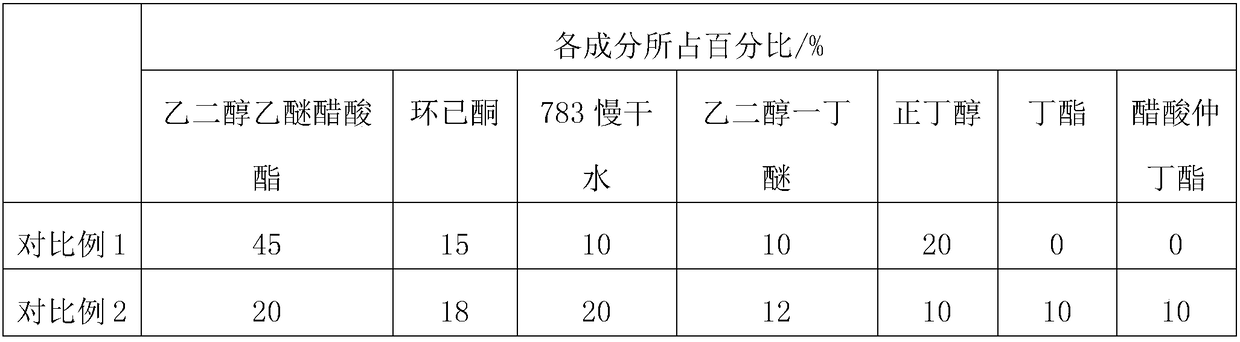

[0022] Take the water transfer film paper that has been printed with the pattern, put the water transfer film paper pattern up on the water surface, spray the water transfer activator on the film paper, dissolve the film carrier in the water, and leave only the ink After about 50-60 seconds, the ink layer begins to disperse. At this time, press the decorative panel of the car dashboard into the water for 3 seconds for transfer printing. The ink layer is tightly attached to the car instrument by the pressure of the water. The texture effect of the surface is formed on the surface of the dashboard decorative board, the transferred automobile dashboard decorative board is washed with water, and then the automobile dashboard decorative board is dried to complete. Among them, the water transfer printing activato...

Embodiment 2

[0024] This embodiment illustrates the water transfer printing activator provided by the present invention and the method for using the water transfer printing activator.

[0025] Take the water transfer film paper that has been printed with the pattern, put the water transfer film paper pattern up on the water surface, spray the water transfer activator on the film paper, dissolve the film carrier in the water, and leave only the ink After about 50-60 seconds, the ink layer begins to disperse. At this time, press the decorative panel of the car dashboard into the water for 3 seconds for transfer printing. The ink layer is tightly attached to the car instrument by the pressure of the water. The texture effect of the surface is formed on the surface of the dashboard decorative board, the transferred automobile dashboard decorative board is washed with water, and then the automobile dashboard decorative board is dried to complete. Among them, the water transfer printing activato...

Embodiment 3

[0027] This embodiment illustrates the water transfer printing activator provided by the present invention and the method for using the water transfer printing activator.

[0028] Take the water transfer film paper that has been printed with the pattern, put the water transfer film paper pattern up on the water surface, spray the water transfer activator on the film paper, dissolve the film carrier in the water, and leave only the ink After about 50-60 seconds, the ink layer begins to disperse. At this time, press the decorative panel of the car dashboard into the water for 3 seconds for transfer printing. The ink layer is tightly attached to the car instrument by the pressure of the water. The texture effect of the surface is formed on the surface of the dashboard decorative board, the transferred automobile dashboard decorative board is washed with water, and then the automobile dashboard decorative board is dried to complete. Among them, the water transfer printing activato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com