Method of increasing water solubility of resveratrol by preparing resveratrol/formaldehyde resin nanospheres, and the resin nanospheres

A water solubility and resveratrol technology, applied in the field of functional materials, can solve the problems of low resveratrol loading rate, resveratrol waste, etc., and achieve uniform and adjustable product size, high biological activity, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

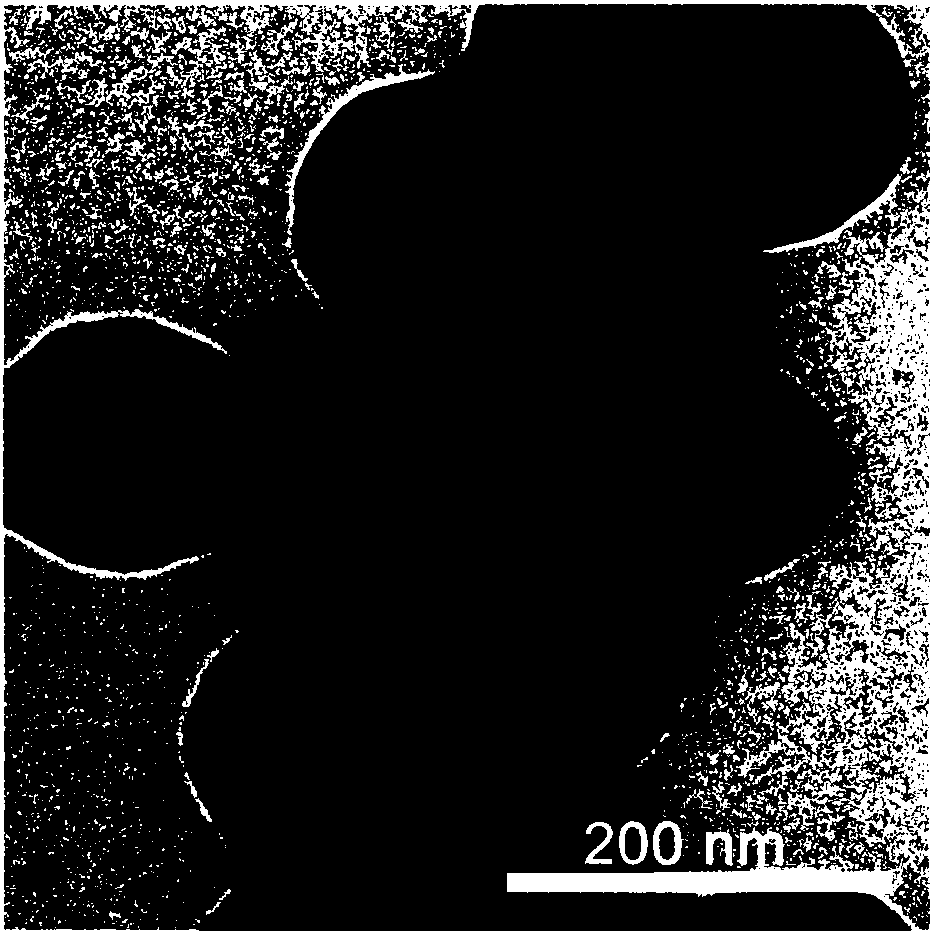

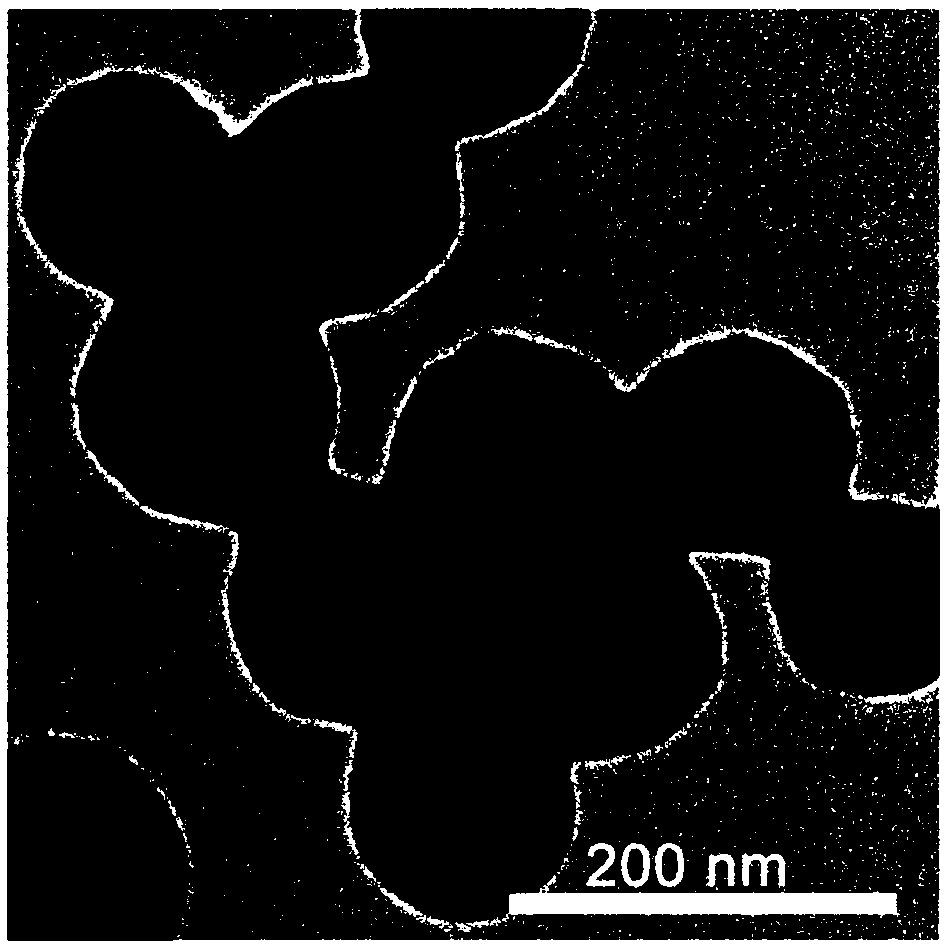

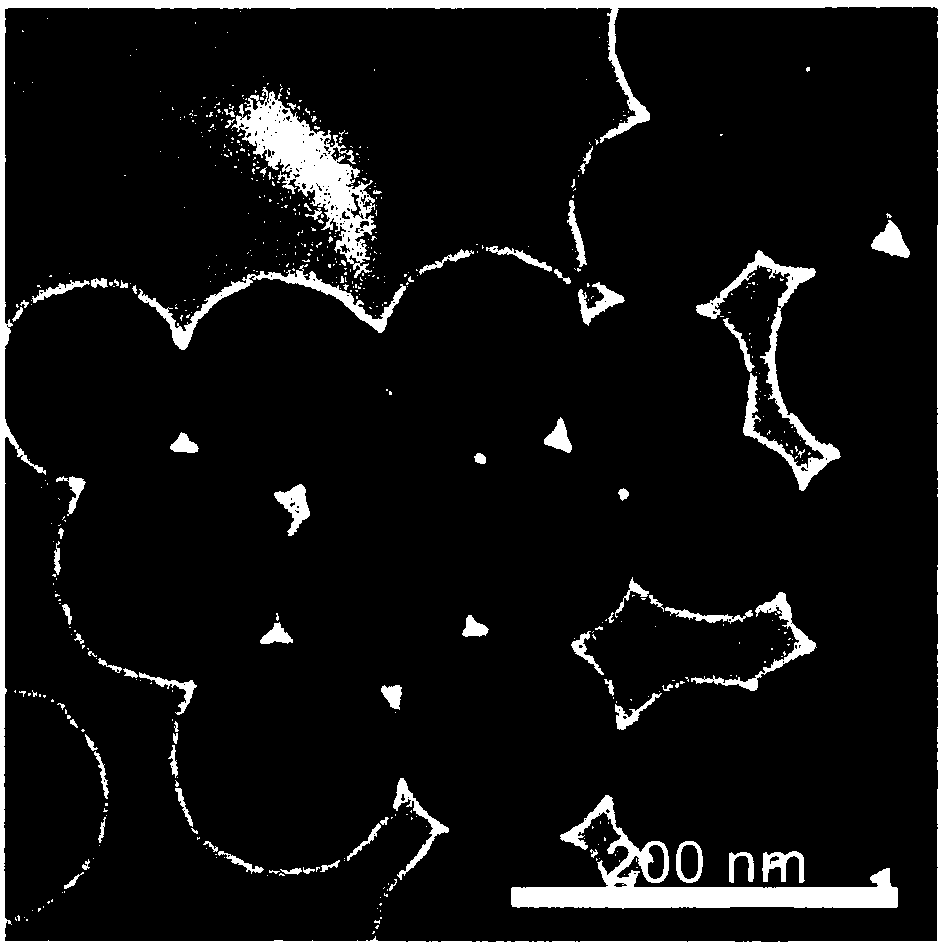

[0019] 9.8mL of water, 4mL of ethanol, 0.1mL of formaldehyde solution (37wt%) and 0.1mL of ammonia water (25wt%) were mixed successively and stirred at room temperature, and finally 1mL of ethanol-dissolved monomer containing 20mg of resveratrol was added. After stirring at room temperature for 45 minutes, centrifuge at a speed of 15,000 rpm for 10 minutes for a total of 4 times to obtain resveratrol / formaldehyde resin nanospheres with an average size of 150 nm. Finally, the resin nanospheres can be dissolved in water to obtain a nanoparticle solution with a concentration of 200 mg / mL.

Embodiment 2

[0021] 11.55mL water, 2.75mL ethanol, 0.1mL formaldehyde aqueous solution (37wt%), 0.1mL ammonia water (25wt%) were mixed successively at room temperature and stirred at room temperature, and finally 1mL ethanol-dissolved monomer containing 20mg resveratrol was added. After stirring at room temperature for 45 minutes, centrifuge at a speed of 15,000 rpm for 10 minutes for a total of 4 times to obtain resveratrol / formaldehyde resin nanospheres with an average size of 120 nm. Finally, the resin nanospheres can be dissolved in water to obtain a nanoparticle solution with a concentration of 180 mg / mL.

Embodiment 3

[0023] 11.8mL of water, 2mL of ethanol, 0.1mL of formaldehyde solution (37wt%) and 0.1mL of ammonia water (25wt%) were mixed successively and stirred at room temperature, and finally 1mL of ethanol-dissolved monomer containing 20mg of resveratrol was added. After stirring at room temperature for 45 minutes, centrifuge at a speed of 15,000 rpm for 10 minutes for a total of 4 times to obtain resveratrol / formaldehyde resin nanospheres with an average size of 110 nm. Finally, the resin nanospheres can be dissolved in water to obtain a nanoparticle solution with a concentration of 160 mg / mL.

[0024] Examples 1-3 illustrate that the size of the resveratrol / formaldehyde resin nanospheres can be adjusted by changing the ratio of water to ethanol, and the size of the nanospheres decreases with the increase of the proportion of water used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com