Boron-adding high-carbon clean steel vacuum induction furnace smelting preparation method

A vacuum induction furnace, carbon pure steel technology, applied in the field of special steel and its smelting, can solve the problems of harmful elements, high inclusion content, limited mechanical properties, plastic deformation of plates, etc., saving precious alloying elements, and low production costs. , the effect of small plastic deformation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing the above-mentioned boron-added high-carbon pure steel (that is, high-strength carbon pure steel). The method uses a vacuum induction furnace as the main equipment of the production process, and the product is prepared by feeding raw materials such as industrial pure iron into the furnace. The preparation method comprises the following steps:

[0028] Step 1, ingredients: industrial pure iron, recarburizer (C ratio 0.7-0.8%, that is, after adding recarburizer, C in the recarburizer accounts for 0.7-0.8% by mass of industrial pure iron), Cr Strips, Mo strips, and V-Fe alloys are used as smelting ingredients.

[0029] Step 2: Vacuum induction furnace smelting:

[0030] Send the above-mentioned smelting ingredients into the vacuum induction furnace, and under the vacuum degree ≤ 20Pa (preferably 1-20Pa), send electricity to melt the ingredients;

[0031] When the molten steel temperature reaches 1580-1600°C (such as 1582°C, 1...

Embodiment 1

[0056] The present embodiment uses 25Kg vacuum induction furnace to smelt, and casts 25Kg shell ingot.

[0057] The high-strength carbon pure steel of the present embodiment is composed of the following mass percentages:

[0058] C

mn

Si

P

S

Cr

Mo

V

B

0.67

0.731

0.289

0.005

0.0006

0.328

0.001

0.18

0.0075

[0059] The balance is Fe and unavoidable impurities.

[0060] The preparation method of the present embodiment comprises the following steps:

[0061] (1) Ingredients: Industrial pure iron, recarburizer (C ratio 0.7-0.8%), Cr bar, Mo bar, V-Fe alloy are used as smelting ingredients.

[0062] (2) Vacuum induction furnace smelting:

[0063] a) Melting: Send the above-mentioned smelting ingredients into a vacuum induction furnace, and under a vacuum degree of 15Pa, send electricity to melt the ingredients;

[0064] b) Refining: When the temperature reaches 1590°C and the vacuum degree is 3Pa, start refini...

Embodiment 2

[0070] The present embodiment uses 25Kg vacuum induction furnace to smelt, and casts 25Kg shell ingot.

[0071] The high-strength carbon pure steel of the present embodiment is composed of the following mass percentages:

[0072] C

mn

Si

P

S

Cr

Mo

V

B

0.71

0.747

0.289

0.004

0.0004

0.341

0.001

0.13

0.0091

[0073] The balance is Fe and unavoidable impurities.

[0074] In the preparation method of this example, except that the amount of elements added in steps (1) and (2)-c) is different, other operations and parameters are the same as in Example 1.

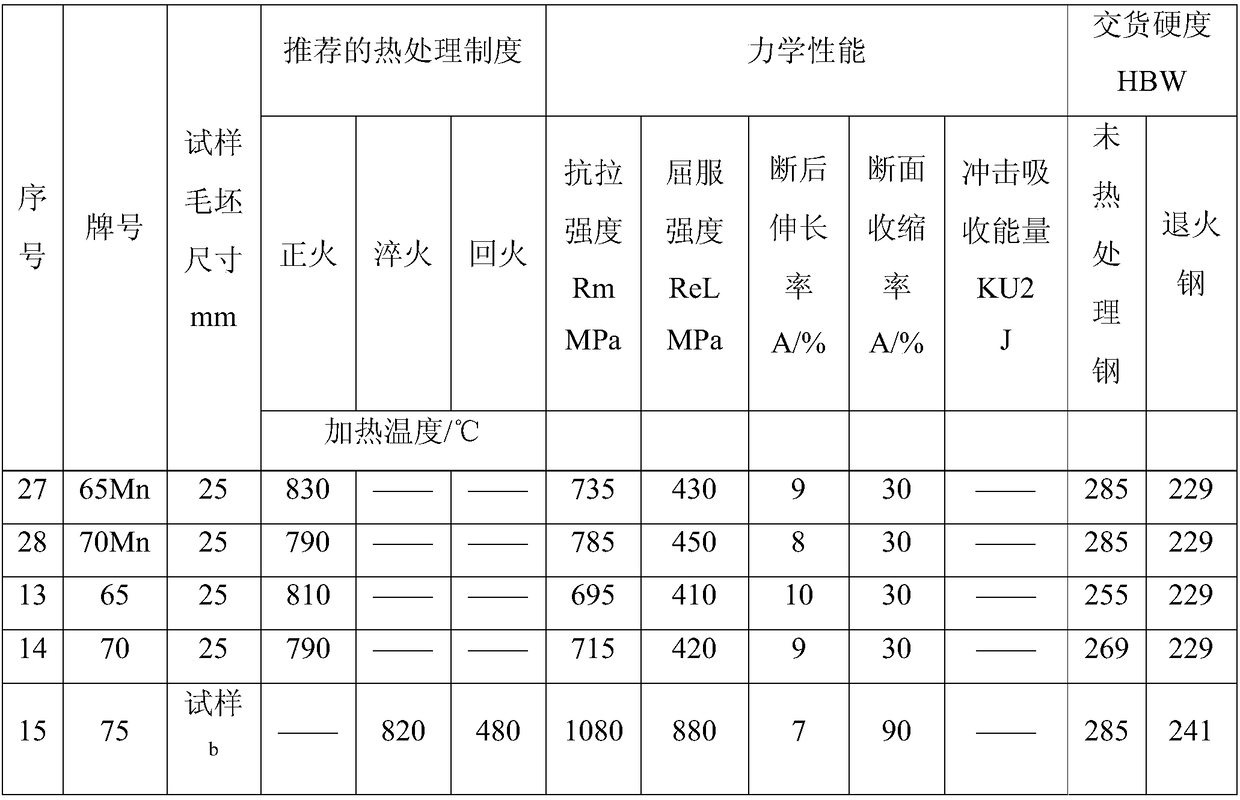

[0075] The mechanical properties of the product obtained in this example are significantly enhanced: the tensile strength Rm is 1453 MPa, the yield strength R0.2 is 1404 MPa, and the elongation is 8.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com