Patents

Literature

36results about How to "Purify molten steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

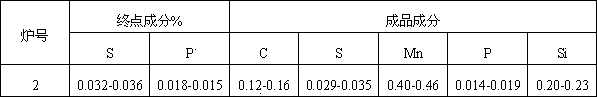

Slab molten steel refining method and steel plate smelting method

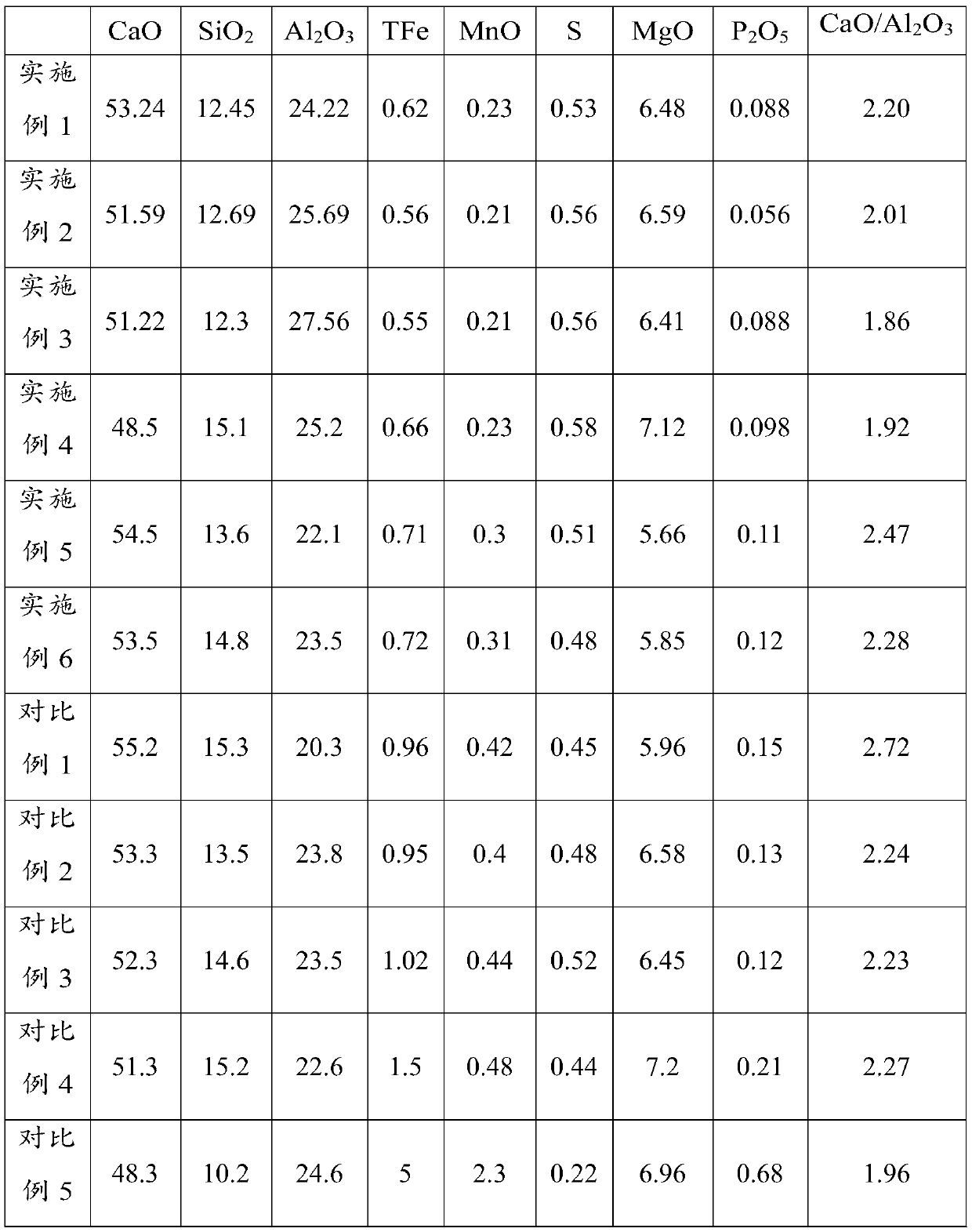

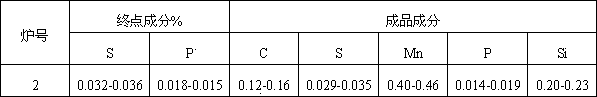

The invention relates to a slab molten steel refining method and a steel plate smelting method, and belongs to the technical field of refining methods. The slab molten steel refining method includes the steps of sequentially adding ferro-aluminum, lime and high alumina slag to molten steel under the bottom argon blowing conditions in the molten steel tapping process of a converter, and controllingthe addition amount of the ferro-aluminum and high alumina slag according to the end point carbon content of the converter. In the refining process of an argon station, top slag is obtained through strong and weak argon stirring by means of the bottom argon blowing. The top slag comprises 45-55 wt% of CaO, 20-30 wt% of Al2O3 and smaller than 1 wt% of TFe and MnO. By controlling the addition amount of the ferro-aluminum and high alumina slag according to the end point carbon content of the converter in the molten steel tapping process of the converter, modifying the top slag through strong andweak argon stirring at the argon station after molten steel tapping, reducing the content of TFe and MnO in the top slag and controlling the components of the top slag, the molten steel can be directly continuously cast and poured after being processed at the argon station, and production cost is reduced.

Owner:SGIS SONGSHAN CO LTD

Magnesium-aluminum alloy core-spun yarn

This invention relates to a magnalium clad wire which is about the metallurgy technology field. Under the steel-making temperature the magnesium steam will transgress from the steel liquid which decrease the concentration of magnesium in the steel. This invention provides a magnalium clad wire to solve this problem. The component of the clad wire core alloy is Mg 5-13%, Al 11-14% and the residual is steel and other impurity. The high solubility characteristic of magnesium in the steel liquid is fully utilized in this invention. The complex magnesium alloy deoxidation technology and the wire-feeding technology are both used in magnesium and deoxidation of steel liquid. It could decrease magnesium gasification speed by adding high melting-point substance and controlling the magnesium concentration. The magnalium clad wire can properly solve the problem of the high magnesium steam under the steel-making temperature and Mg is easily to be oxidized by steel residue and could not add to the steel liquid.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Preparation method of normal temperature solidified magnesium carbon brick

The invention relates to a preparation method of a normal temperature solidified magnesium carbon brick, belonging to the technical field of fireproof material. The preparation comprises the following steps: mixing small size magnesia and calcium oxide powder in a mixer to obtain a premix; adding the rest magnesia and phenolic resin binder and carbon in a mixing roll for mixing; then adding the premix for mixing to obtain mixed mud; putting the mixed mud in a press die for forcing molding to obtain a formed magnesium carbon brick; and putting the formed magnesium carbon brick for preservation at room temperature for 2-4 days to obtain the magnesium carbon brick. The mixing order and mixing time are different depending on the different selected mixing devices. If a tilting reverse flow mixer is used for mixing, the premixing technology can be omitted, and the required materials are directly put into the mixer for mixing to obtain the mixed mud. According to the invention, the technologies of seting, baking and the like are omitted, energy and labor are saved, and the discharge of pollutant is reduced.

Owner:江苏苏嘉集团新材料有限公司

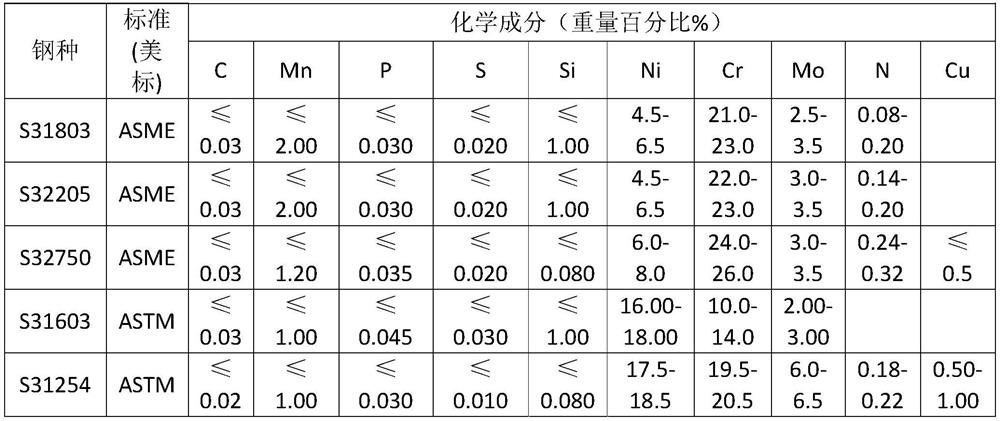

Super advanced double-phase stainless steel smelting process method of CD3MWN material

ActiveCN108823348AIncrease contentReduce precipitationProcess efficiency improvementHydrogenDouble phase

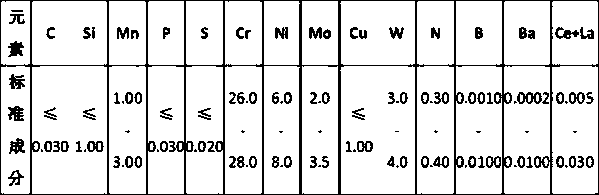

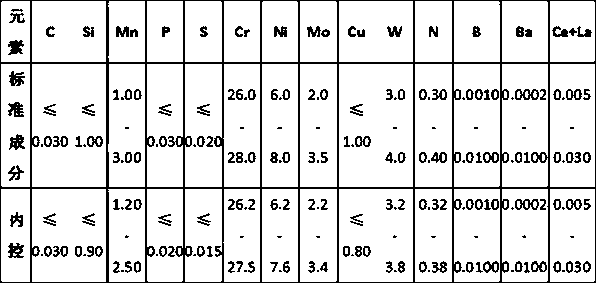

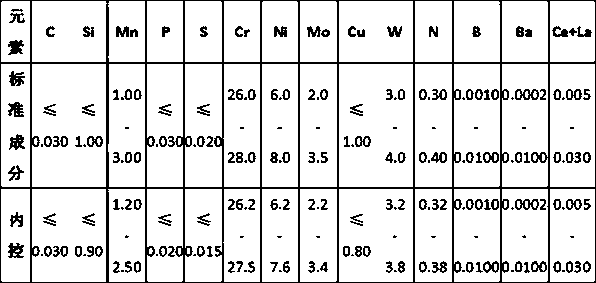

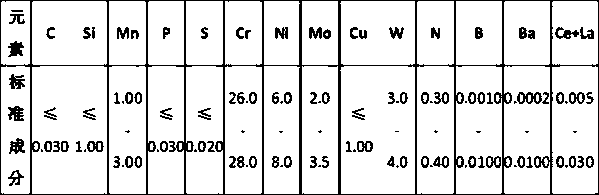

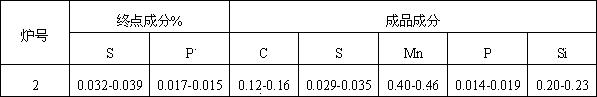

The invention relates to a super advanced double-phase stainless steel smelting process method of a CD3MWN material. According to the invention, internal control components during double-phase stainless steel smelting is designed, wherein C is less than or equal to 0.030 wt%, Si is less than or equal to 0.90 wt%, Mn is 1.20-2.50 wt%, P is less than or equal to 0.020 wt%, S is less than or equal to0.015 wt%, and Cr is 26.2-27.5 wt%, Ni is 6.2-7.6 wt%, Mo is 2.2-3.4 wt%, Cu is less than or equal to 0.80 wt%, W is less than or equal to 0.80 wt%, N is 0.32-0.38 wt%, B is 0.0010-0.0100 wt%, Ba is0.0002-0.0100 wt%, and Ce+La is 0.005- 0.030 wt%; and %Cr+3.3 (%Mo+0.5%W)+16%N is less than or equal to 45, the content of trace elements B, Ba, Ce, and La can be precisely controlled; the N content is increased to 0.30% or more, and at the same time, nitrogen holes in the casting can be avoided; and the content of harmful elements such as sulfur, oxygen, hydrogen and the like is minimized to improve the purity of the molten steel. The cast casting has high strength and excellent corrosion resistance. In the stainless steel, a ferrite phase and an austenite phase are close to 50%, the castinglife is prolonged. the production costs are greatly reduced, and purposes of energy saving and environmental protection can be realized.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

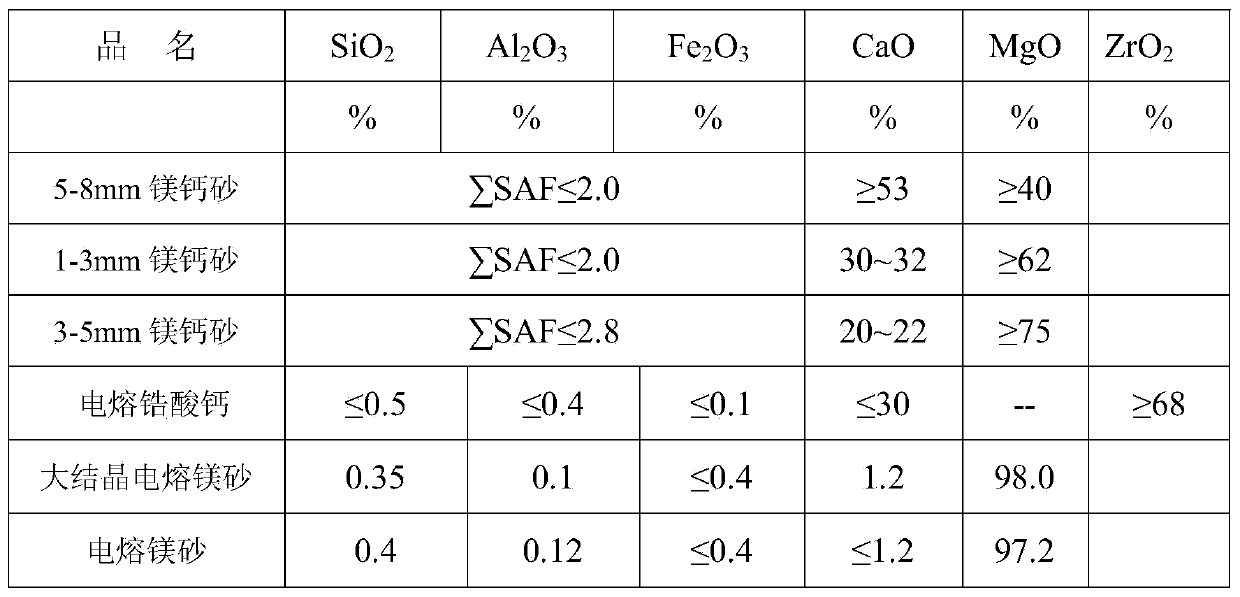

Dolomite-periclase-calcium zirconate composite fireproof material and preparation method thereof

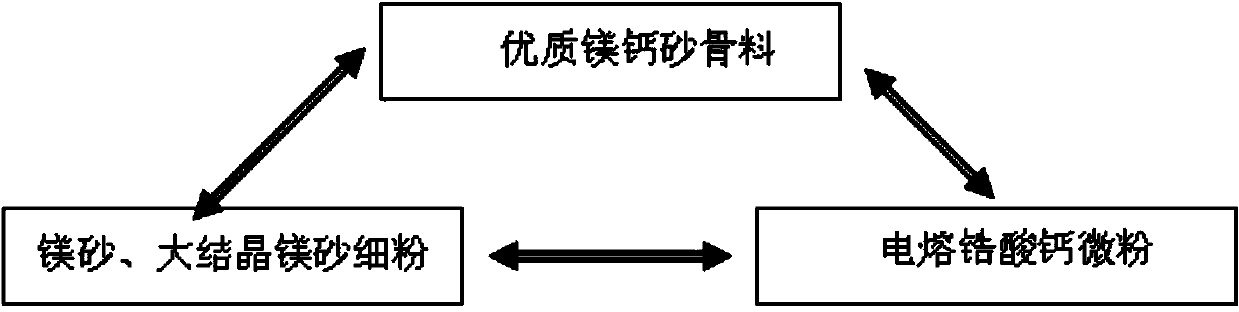

The invention relates to a high-quality dolomite-periclase-calcium zirconate composite fireproof material suitable for smelting stainless steel, special steel AOD furnace and refining ladles. The adopted raw materials mainly comprise, by weight, 8-10% of magnesium calcium sand with a particle size of 5-8 mm, 9-18% of magnesium calcium sand with a particle size of 3-5 mm, 10-22% of magnesium calcium sand with a particle size of 1-3 mm, 5-10% of calcium zirconate with a particle size of 0.5-1 mm, 5-10% of magnesia with a particle size of 0.5-1 mm, 3-10% of 600 mesh electric melting calcium zirconate, 15-24% of magnesia with a particle size of less than or equal to 0.5 mm, 3-10% of 400 mesh 98 large crystal magnesia, 1-3% of a binding agent, and 1-2% of a sintering agent, wherein the raw materials are subjected to mixing, molding, sintering, finished product inspection, package and other steps to prepare the material.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

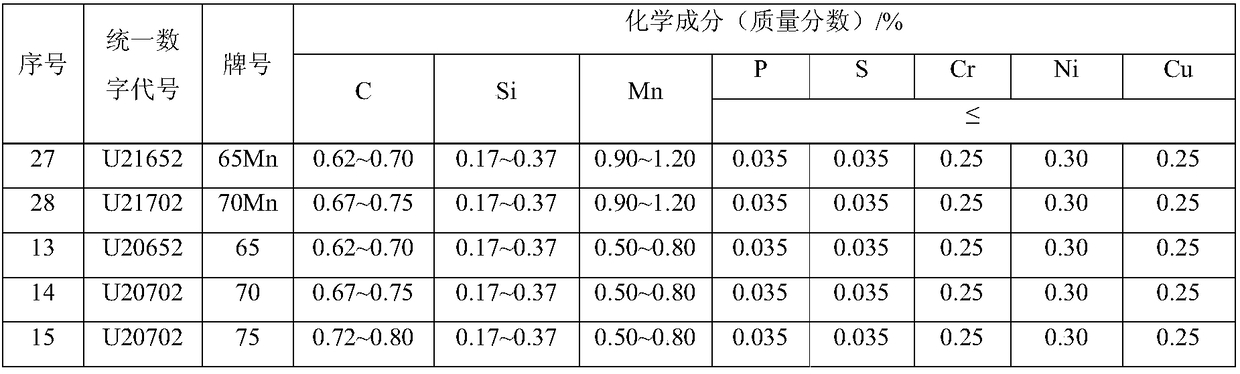

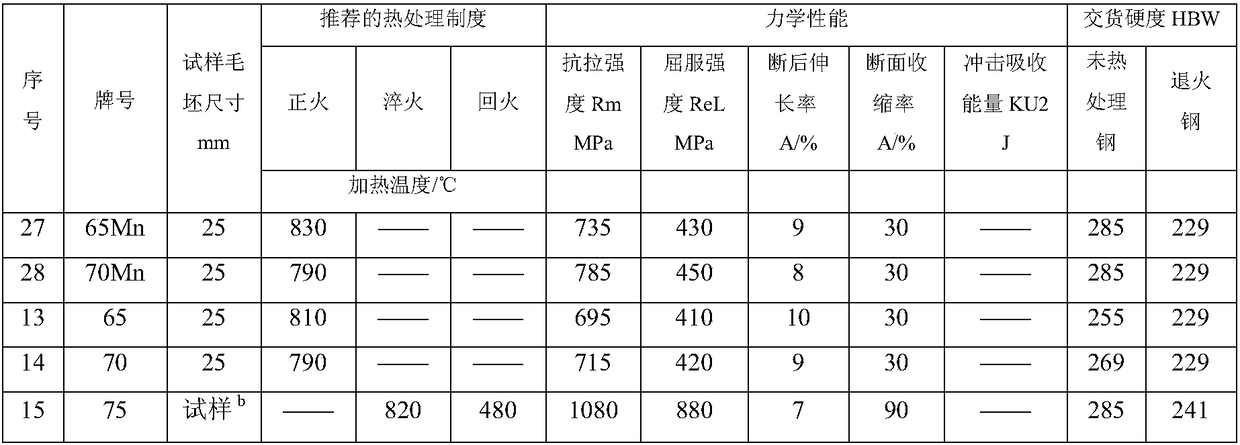

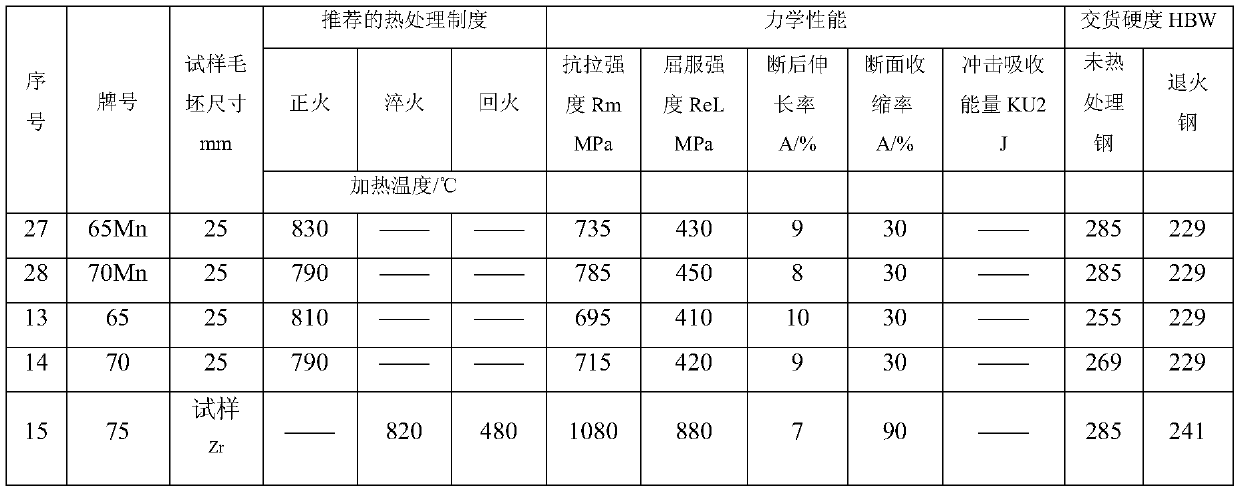

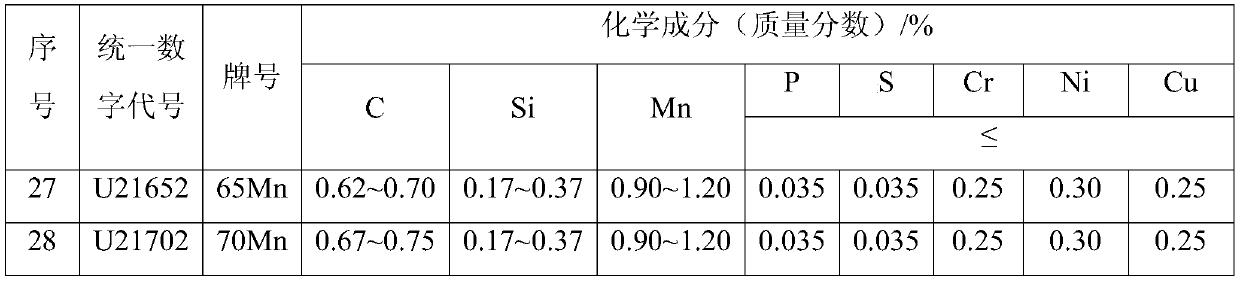

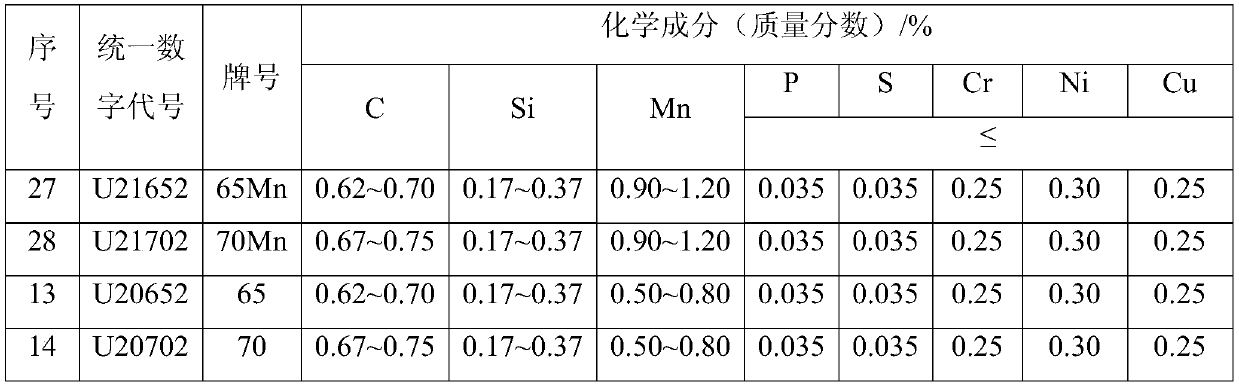

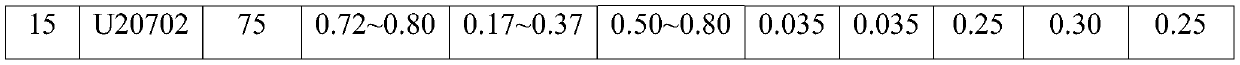

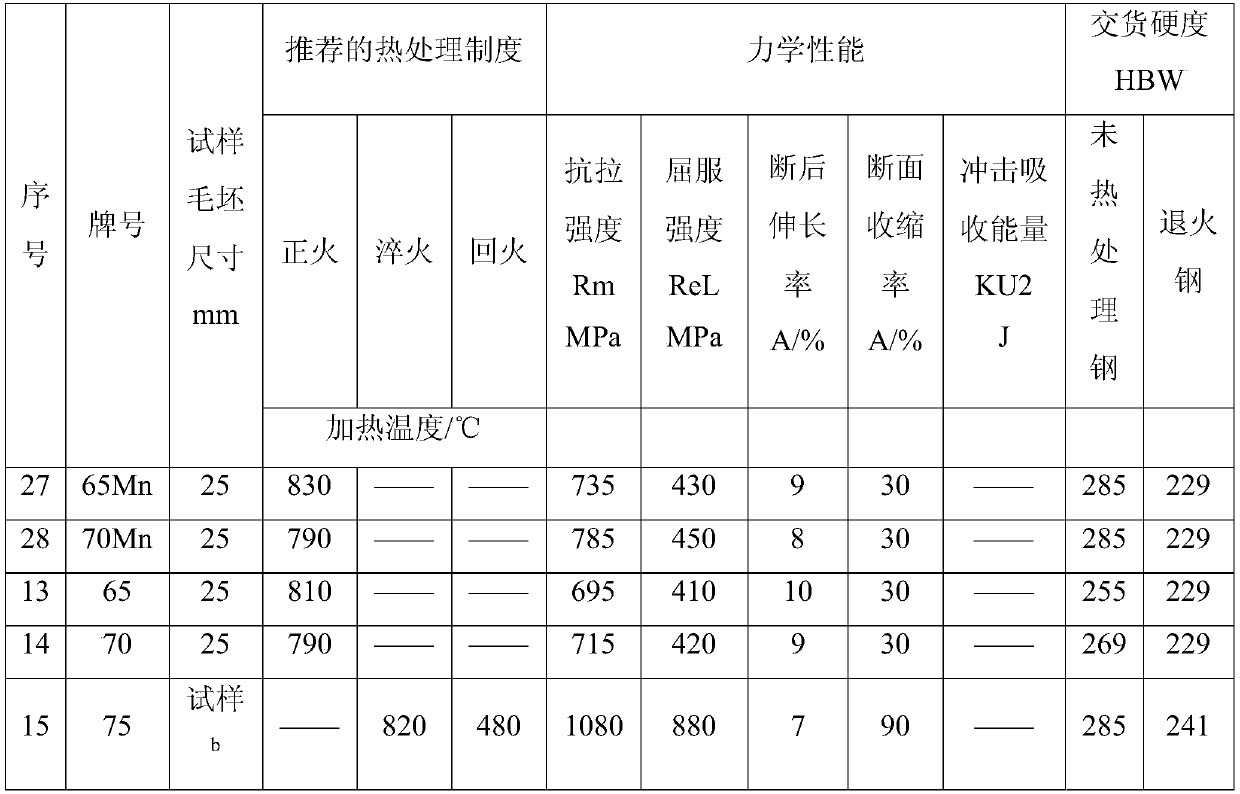

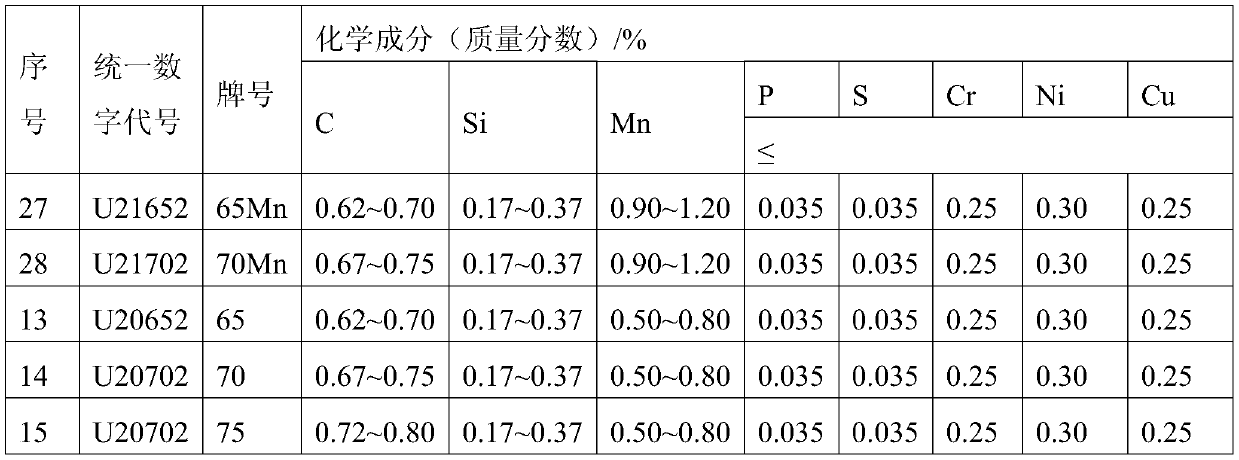

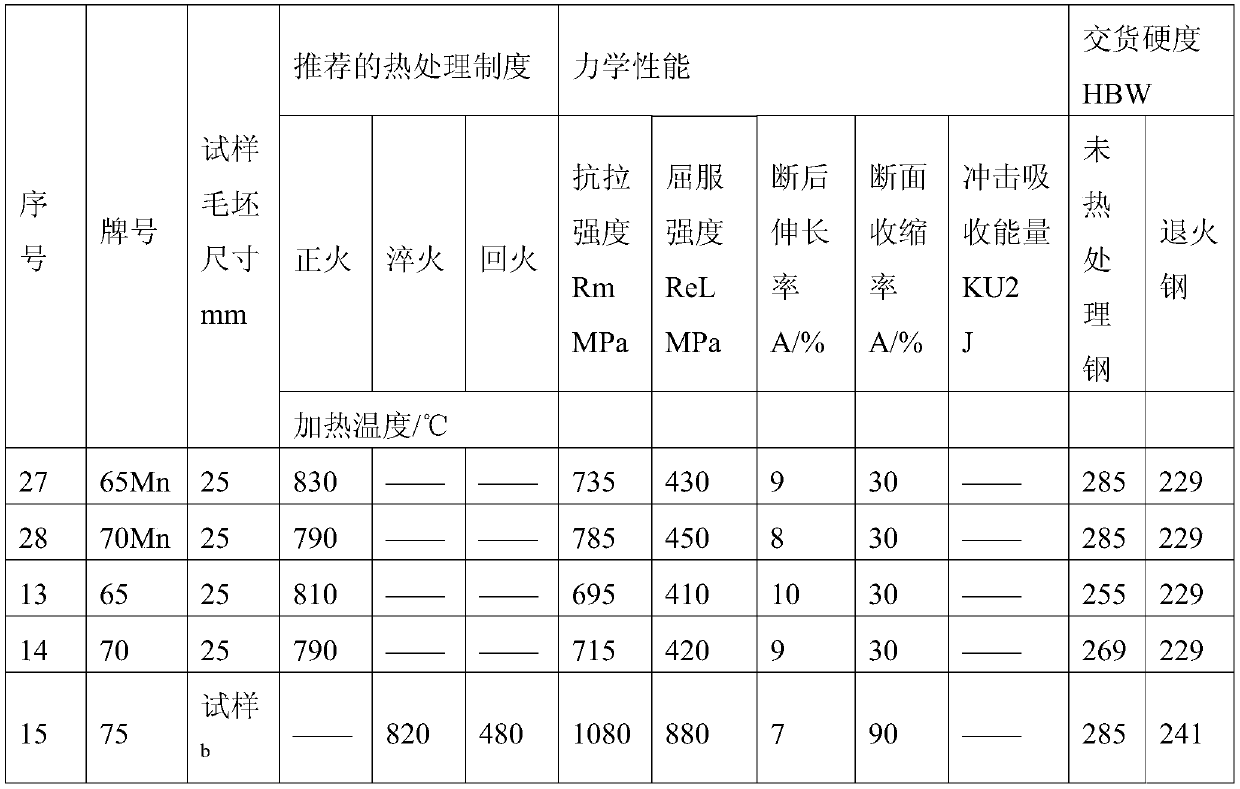

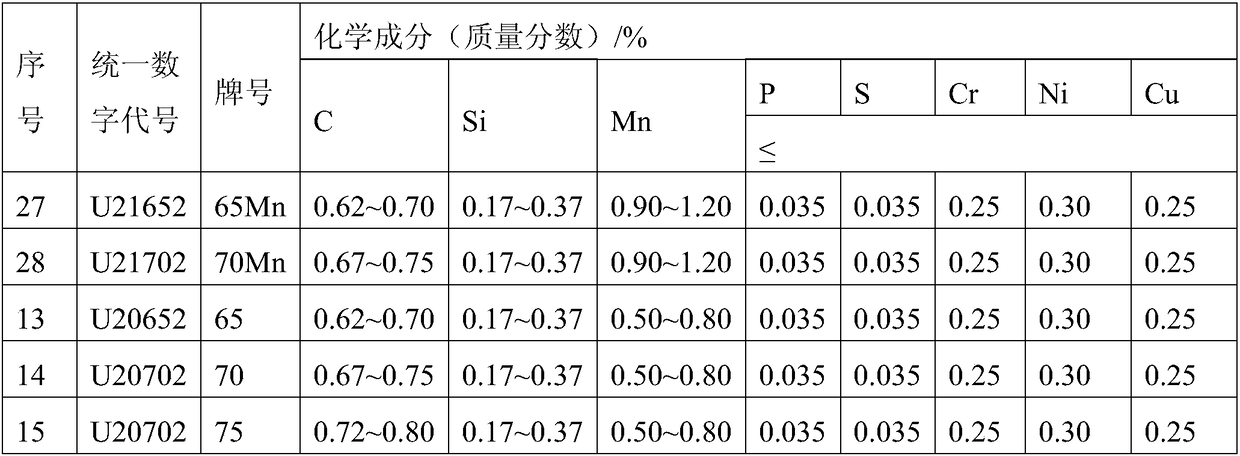

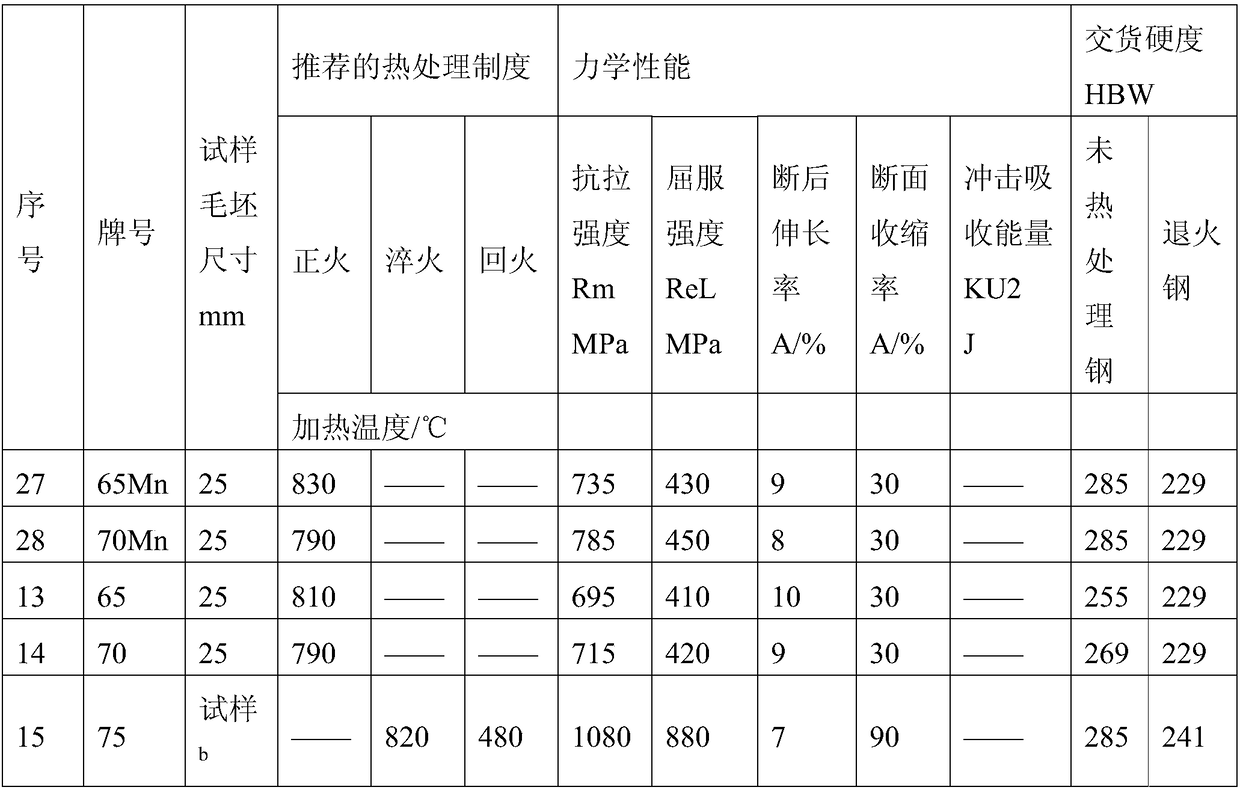

Boron-added high-carbon and microalloyed high-strength carbon clean steel and preparation method thereof

ActiveCN108149133AImprove mechanical propertiesReduce contentManufacturing convertersProcess efficiency improvementHigh carbonHigh intensity

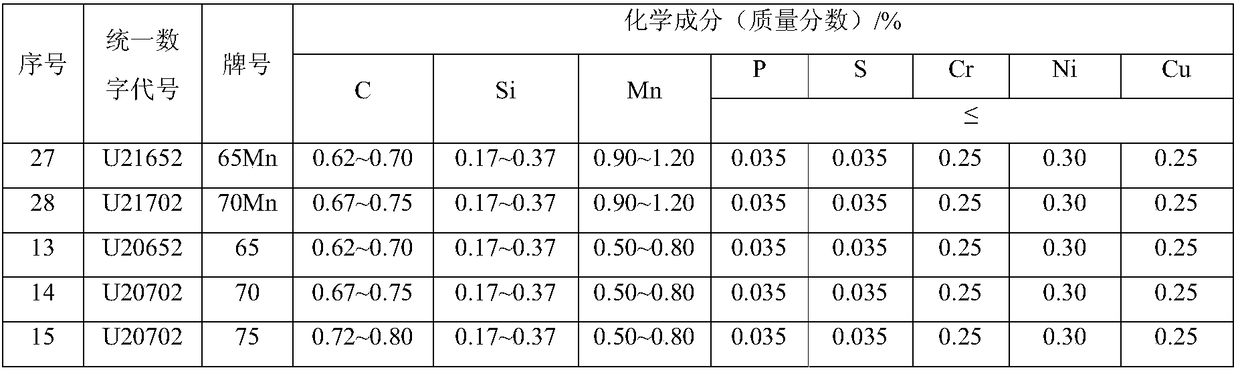

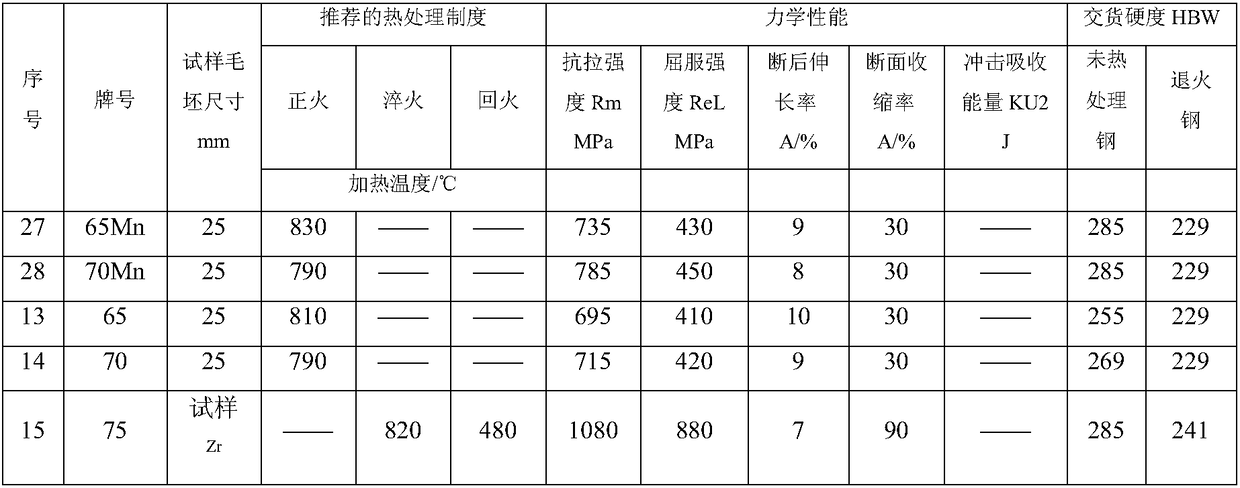

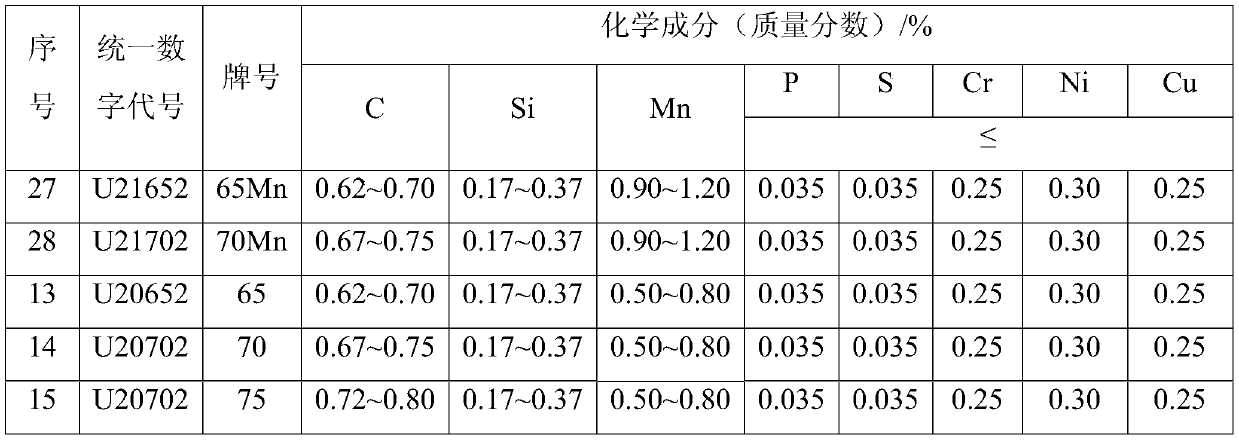

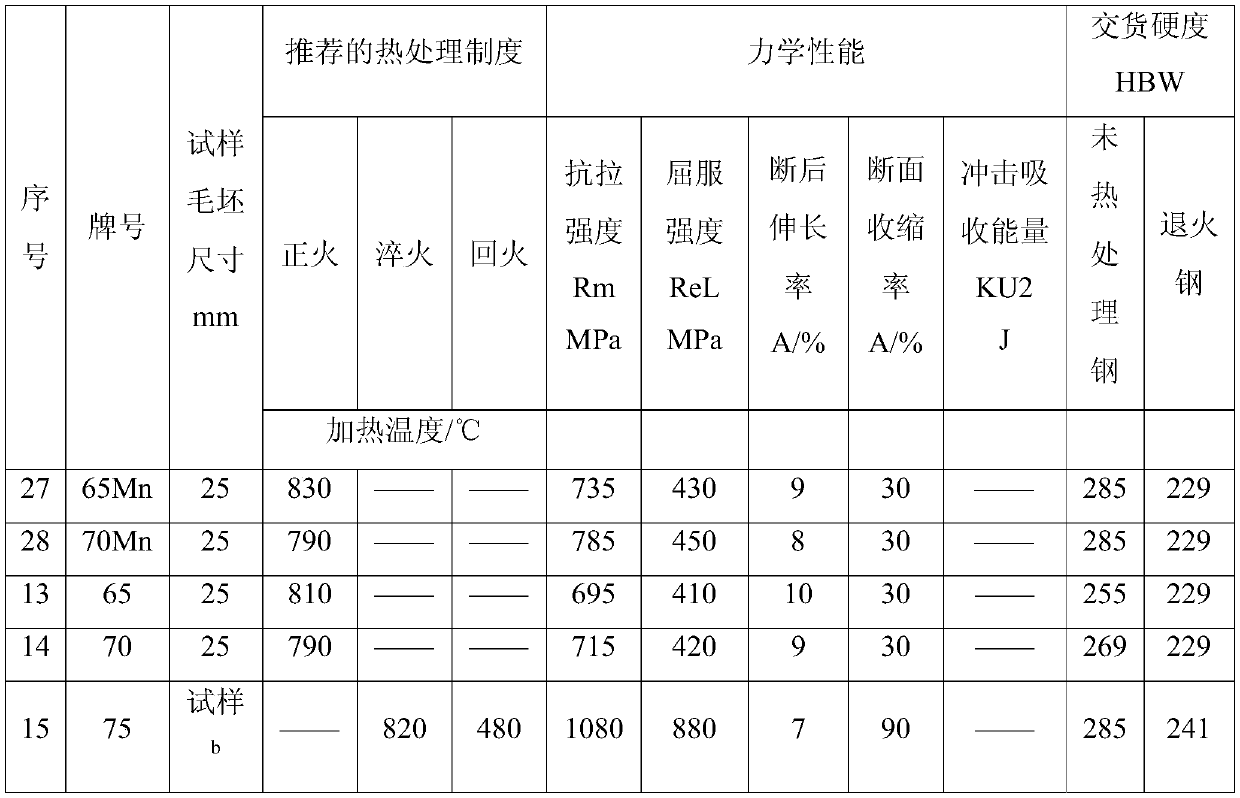

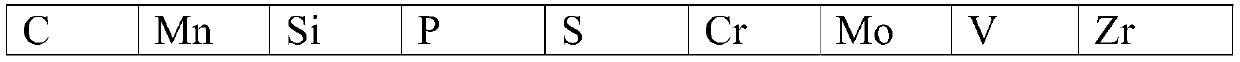

The invention belongs to the technical field of special steel and special steel smelting, and relates to boron-added high-carbon and microalloyed high-strength carbon clean steel and a preparation method thereof. The high-strength carbon clean steel consists of the following components of, by mass percent, 0.67-0.75% of C, 0.15-0.37% of Si, 0.30-0.80% of Mn, less than or equal to 0.012% of P, lessthan or equal to 0.006% of S, 0.20-0.50% of of Cr, less than or equal to 0.30% of Mo, less than or equal to 0.30% of V, 0.002-0.100% of B, and the balance Fe and unavoidable impurities. The contentsof harmful elements, namely, S, P, O and N are further reduced, the inclusion contents are reduced, and molten steel is purified, so that the mechanical property of the boron-added high-carbon and microalloyed high-strength carbon clean steel is improved substantially; and through the synergistic effect of the reasonable matching ratios of the various components of the boron-added high-carbon andmicroalloyed high-strength carbon clean steel and the steps and parameters of the preparation method, the mechanical property of the boron-added high-carbon and microalloyed high-strength carbon cleansteel is further improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Steel-making production deoxidizing agent and production process thereof

The invention relates to a steel-making production deoxidizing agent and a production process thereof, and is characterized in that the deoxidizing agent is a mixture prepared by the following raw materials by the weight percentage: 40-45% of aluminum, 25-35% of a limestone powder, 2-3% of polyvinyl alcohol, 5-8% of industrial starch, and 2-5% of a bentonite powder. The production of the deoxidizing agent comprises the following steps: mixing the raw materials; granulating; and drying: carrying out drying treatment on the deoxidizing agent particles after molding at the temperature of 100-200 DEG C. The steel-making production deoxidizing agent has simple production process, and does not produce three-waste pollution in the production. With use of the deoxidizing agent, oxygen in molten steel can be removed, and the deoxidizing agent can undergo a reaction with deoxidation products to form low-melting silicate compounds, a steel slag layer is caused to float upward and be separated, and inclusions in the molten steel are effectively removed, so that the function of purifying the molten steel is achieved, the occurrence of flocculant flow at a continuous casting water gap is avoided, the number of continuous casting tanks can be increased, the quality of steel is improved, on-site operation is facilitated, and raw material consumption is reduced.

Owner:张福平

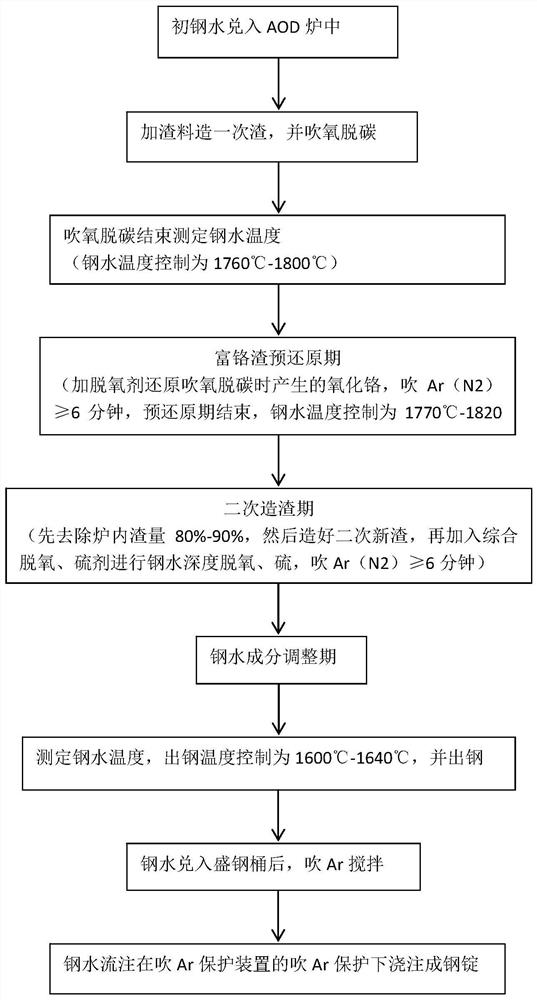

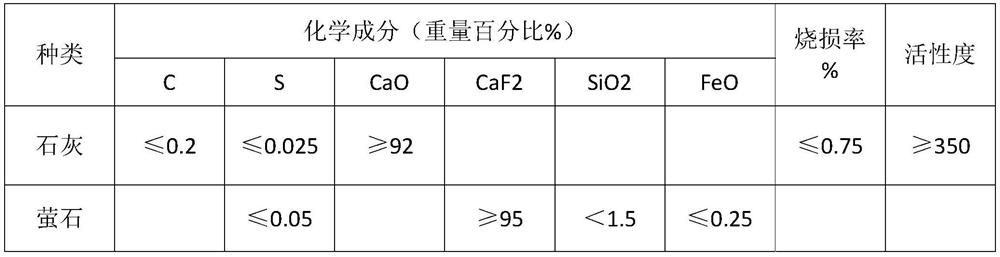

Comprehensive deoxidizing and desulfurizing process for smelting stainless steel by using small-capacity AOD (Argon Oxygen Decarburization) furnace

The invention discloses a comprehensive deoxidizing and desulfurizing process for smelting stainless steel by using a small-capacity AOD (Argon Oxygen Decarburization) furnace. The comprehensive deoxidizing and desulfurizing process is characterized in that the furnace capacity of the AOD furnace is less than or equal to 10 tons, and primary molten steel added into the AOD furnace meets the specified requirements. After the oxygen-blowing decarburization period ends, a chromium-rich slag pre-reduction period begins, Ar(N2) is blown for more than or equal to 6 minutes, and the temperature of the molten steel is controlled to be 1770-1820 DEG C. In the secondary slagging period, after 80 to 90 percent of slag in the furnace is removed, lime and fluorite meeting the specified requirements are added; and after secondary new slag is formed, a comprehensive deoxidizing and desulfurizing agent which is composed of a deoxidizing agent metal Al block, a composite deoxidizing and desulfurizing agent Si-Ca block and a composite deoxidizing and desulfurizing agent Si-Ca-Ba-Al block and meets the specified requirements is added, and Ar(N2) is blown for more than or equal to 6 minutes. The tapping temperature is 1600-1640 DEG C. According to the process, on the basis of the prior art, the oxygen content of steel is remarkably reduced, and the quality of high-end stainless steel for cold (hot) machining deformation is improved.

Owner:HAIYAN ZHONGDA METAL ELECTRONIC MATERIAL CO LTD

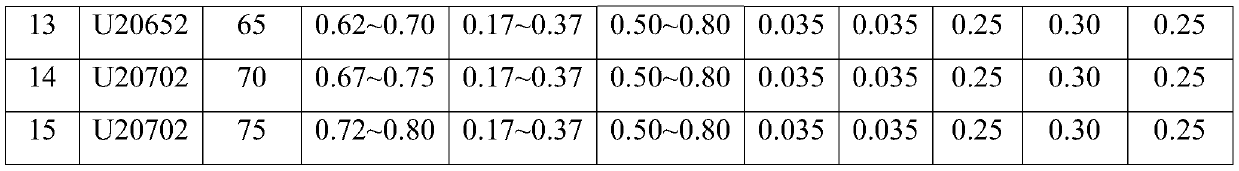

Zirconium-added high-carbon microalloyed high-strength carbon clean steel and preparation method

ActiveCN108193017AImprove mechanical propertiesReduce contentManufacturing convertersProcess efficiency improvementHigh carbonHigh intensity

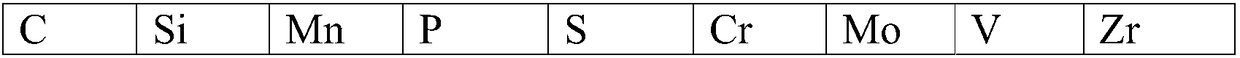

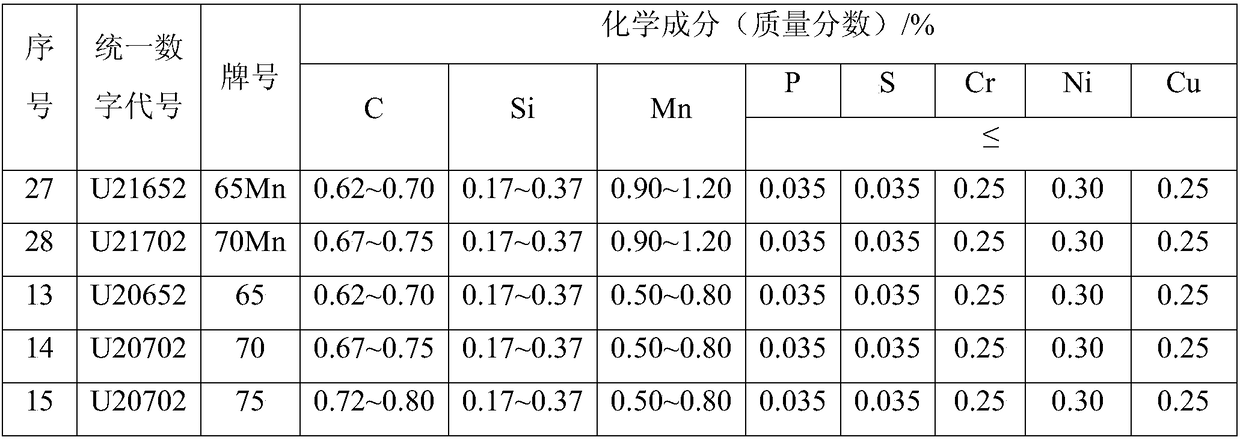

The invention belongs to the technical fields of special steels and smelting thereof and relates to a zirconium-added high-carbon microalloyed high-strength carbon clean steel and a preparation methodthereof. The high-strength carbon clean steel comprises, by mass percentage, 0.67-0.75% of C, 0.15-0.37% of Si, 0.30-0.80% of Mn, less than or equal to 0.012% of P, less than or equal to 0.006% of S,0.20-0.50% of Cr, less than or equal to 0.30% of Mo, less than or equal to 0.30% of V, 0.002-0.100% of Zr and the balance Fe and inevitable impurities. According to the high-strength carbon clean steel, the contents of the harmful elements S, P, O and N are further lowered; the inclusion content is lowered; molten steel is purified; mechanical performance of the steel can be greatly improved; andreasonable mixing ratios of all components of the high-strength carbon clean steel and steps and parameters of the preparation method cooperatively act to jointly further improve mechanical performance of the high-strength carbon clean steel.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Boron-adding high-carbon clean steel vacuum induction furnace smelting preparation method

The invention belongs to the technical field of special steel and smelting of the special steel, and relates to a boron-adding high-carbon clean steel vacuum induction furnace smelting preparation method. Boron-adding high-carbon clean steel comprises, by mass, 0.67%-0.75% of C, 0.15%-0.37% of Si, 0.30%-0.80% of Mn, not larger than 0.012% of P, not larger than 0.006% of S, 0.20%-0.50% of Cr, not larger than 0.30% of Mo, not larger than 0.30% of V, 0.002%-0.100% of B and the balance Fe and inevitable impurities. The preparation method comprises the following steps of vacuum induction furnace smelting, smelting, continuous casting and the like. By means of the method, the mechanical property of the steel can be greatly improved, the product tensile strength Rm is larger than or equal to 1450MPa, the yield strength R0.2 is larger than or equal to 1350 MPa, a plate of the steel is used on a sintering saw web mother blank, the produced plastic deformation damage is small, the service lifeof the steel is prolonged, and the production cost of the steel is low.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

RH refining method for reducing total oxygen content of ultra-low carbon steel tundish

InactiveCN109880974AReduce the binding forceAvoid cloggingProcess efficiency improvementOxygen contentLiquid steel

The invention relates to an RH refining method for reducing the total oxygen content of an ultra-low carbon steel tundish and belongs to the technical field of continuous casting. The RH refining method comprises the steps that aluminum is added in converter molten steel after decarbonizing and / or degassing treatment to perform deoxidizing treatment, maintaining is performed for at least 3 minutes, and then a silicon-containing metal is added in to obtain the refined molten steel; and in percentage by mass and in part per million concentration, the silicon content in the refined molten steel is 90-110 ppm, the [Si] content in liquid steel is increased, the fact that RH is finished to the tundish pouring process is achieved, when the molten steel comes in contact with air, combination of Aland oxygen is reduced to generate Al2O3, so that the method for reducing the tundish oxygen content is achieved, the fact that the oxygen content in the refined molten steel is less than or equal to10 ppm is achieved, and the RH refining method for reducing the total oxygen content of the ultra-low carbon steel tundish has the effects of purifying the molten steel and avoiding nozzle blocking.

Owner:SHOUGANG CORPORATION

Silicon-manganese-calcareous shale deoxidizer and preparation method thereof

The invention discloses a silicon-manganese-calcareous shale deoxidizer and a preparation method thereof. The silicon-manganese-calcareous shale deoxidizer comprises the following raw materials in parts by weight: 40-50 parts of quartz sand, 15-20 parts of black manganese ore, 5-10 parts of celestine, 50-60 parts of limestone, 20-30 parts of calcareous shale, 5-10 parts of scrap iron, 10-20 parts of coal ash, 10-15 parts of vermiculite and 5-10 parts of sepiolite. The silicon-manganese-calcareous shale deoxidizer disclosed by the invention has the advantage that a formula is reasonable and the calcareous shale, the scrap iron, the coal ash, the vermiculite and the sepiolite are adopted as raw materials, so that the deoxidizer has a good deoxidizing effect, the content of nonmetal impurities in steel can be reduced, the forms of the impurities can be changed, molten steel is purified, the liquidity of the molten steel is improved, the continuous casting process of a molten steel blank is smooth, no accretion is generated at a continuous casting nozzle, thus, the smooth casting production is facilitated, the use performance of the steel is improved and the service life of the steel is prolonged; and the steelmaking cost is reduced.

Owner:芜湖县天海耐火炉料有限公司

Silicon-manganese coal ash deoxidier for steelmaking and preparation method thereof

The invention discloses a silicon-manganese coal ash deoxidier for steelmaking and a preparation method of the silicon-manganese coal ash deoxidier. The silicon-manganese coal ash deoxidier comprises the following raw materials in parts by weight: 90 to 110 parts of quartz sand, 10 to 15 parts of calcareous shale, 20 to 25 parts of coal ash, 10 to 15 parts of fluorite, 3 to 5 parts of charcoal, 5 to 8 parts of waste aluminum powder, 25 to 30 parts of attapulgite and 10 to 15 parts of black manganese ore. The silicon-manganese coal ash deoxidier has rationality in formula; and the coal ash, the charcoal and the attapulgite are adopted for serving as the raw materials. The deoxidier has good deoxidizing effect; with the adoption of the deoxidier, the contents of nonmetal impurities in the steel can be reduced, the form of the impurities can be changed, the molten steel can be purified, the liquidity of the molten steel can be improved, and the molten steel continuous casting process is smooth; and the continuous casting water ports are out of nodules, thus the continuous casting can be smoothly carried out, the service performance and the service life of steel can be improved and prolonged, and the cost of steelmaking can be reduced.

Owner:芜湖县天海耐火炉料有限公司

A zirconium-added high-carbon, micro-alloyed high-strength carbon pure steel and its preparation method

ActiveCN108193017BImprove mechanical propertiesReduce contentManufacturing convertersProcess efficiency improvementMolten steelZirconium

The invention belongs to the technical fields of special steels and smelting thereof and relates to a zirconium-added high-carbon microalloyed high-strength carbon clean steel and a preparation methodthereof. The high-strength carbon clean steel comprises, by mass percentage, 0.67-0.75% of C, 0.15-0.37% of Si, 0.30-0.80% of Mn, less than or equal to 0.012% of P, less than or equal to 0.006% of S,0.20-0.50% of Cr, less than or equal to 0.30% of Mo, less than or equal to 0.30% of V, 0.002-0.100% of Zr and the balance Fe and inevitable impurities. According to the high-strength carbon clean steel, the contents of the harmful elements S, P, O and N are further lowered; the inclusion content is lowered; molten steel is purified; mechanical performance of the steel can be greatly improved; andreasonable mixing ratios of all components of the high-strength carbon clean steel and steps and parameters of the preparation method cooperatively act to jointly further improve mechanical performance of the high-strength carbon clean steel.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

A zirconium-added high-carbon pure steel electric arc furnace smelting preparation method

ActiveCN108220771BImprove mechanical propertiesReduce contentElectric arc furnaceUltimate tensile strength

The invention belongs to the technical field of special steel and smelting of the steel, and relates to a zirconium-added high carbon pure steel electric arc furnace smelting preparing method. The zirconium-added high-carbon pure steel is composed of components including 0.67 to 0.75% of C, 0.15 to 0.37% of Si, 0.30 to 0.80% of Mn, not larger than 0.012% of P, not larger than 0.006% of S, 0.20 to0.50% of Cr, not larger than 0.30% of Mo, not larger than 0.30% of V, 0.002 to 0.100% of Zr, and the balance Fe and inevitable impurities. The preparing method comprises the steps of electric arc furnace smelting, LF, continuous casting treatment and the like. According to the performance results of a prepared product, the tensile strength Rm is larger than or equal to 1400 MPa, the yield strengthR0.2 is larger than or equal to 1300 MPa, the board is used for a sintered saw blade mother board, plastic deformation damage is small, the service life is prolonged, and the steel production cost islow.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

A method for smelting ultra-advanced duplex stainless steel made of cd3mwn

ActiveCN108823348BIncrease contentReduce precipitationProcess efficiency improvementSmelting processSS - Stainless steel

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Silicon-barium attapulgite deoxidier for steelmaking and preparation method thereof

The invention discloses a silicon-barium attapulgite deoxidier for steelmaking and a preparation method of the silicon-barium attapulgite deoxidier. The silicon-barium attapulgite deoxidier comprises the following raw materials in parts by weight: 70 to 80 parts of quartz sand, 3 to 5 parts of celestite, 10 to 15 parts of kaolinite, 10 to 15 parts of limestone, 3 to 5 parts of table salt, 5 to 10 parts of charcoal, 5 to 10 parts of attapulgite, 20 to 30 parts of vermiculite and 10 to 15 parts of black manganese ore. The silicon-barium attapulgite deoxidier has rationality in formula; and the celestite, the table salt, the charcoal, the attapulgite and the vermiculite are adopted as the raw materials. The deoxidier has good effect on deoxidizing; with the adoption of the deoxidier, the contents of nonmetal impurities in the steel can be reduced, the form of the impurities can be changed, the molten steel can be purified, the liquidity of the molten steel can be improved, the molten steel is smooth in continuous casting; and the continuous casting water ports are out of nodules, thus the continuous casting can be smoothly carried out, the service performance and the service life of steel can be improved and prolonged, and the cost of steelmaking can be reduced.

Owner:芜湖县天海耐火炉料有限公司

Alloy material for water pipe and preparation method thereof

The invention discloses an alloy material for a water pipe. The material is characterized by comprising, by weight, silica with the SiO2 content greater than or equal to 97%, 8-15% of lime with the CaO content greater than or equal to 90%, 10-15% of barite with the BaSO4 or BaCO3 content greater than or equal to 80%, 30-35% of coke with the C content greater than or equal to 80%, 3-6% of fluoritewith the CaF2 content greater than or equal to 80% and the balanced steel chips, 0.5-1% of AL, S less than or equal to 0.05%, P less than or equal to 0.05%, 2%-4% of silicon dioxide, 15%-20% of talcumpowder, 10%-20% of mica powder, 3%-5% of micro silica powder and the balanced Fe. The alloy material has the advantages of being safe, hygienic, healthy and durable, the problem of plastic pipeline contamination is eliminated, the price is reduced a lot compared with a copper powder, and the alloy material is a priority water pipe material.

Owner:丹阳市延陵镇优越合金厂

A vacuum induction furnace smelting preparation method of zirconium-added high-carbon pure steel

ActiveCN108300933BImprove mechanical propertiesReduce contentElectric furnaceProcess efficiency improvementUltimate tensile strengthVacuum induction furnace

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Silicon-barium-potassium system deoxidier for steelmaking and preparation method thereof

The invention discloses a silicon-barium-potassium system deoxidier for steelmaking and a preparation method of the silicon-barium-potassium system deoxidier. The silicon-barium-potassium system deoxidier comprises the following raw materials in parts by weight: 70 to 75 parts of quartz sand, 30 to 40 parts of barite, 5 to 10 parts of potassium feldspar, 10 to 15 parts of fluorite, 15 to 20 parts of bauxite, 3 to 5 parts of charcoal and 20 to 25 parts of vermiculite. The silicon-barium-potassium system deoxidier has rationality in formula; and the potassium feldspar, the fluorite, the bauxite, the charcoal and the vermiculite serve as the raw materials. The deoxidier has good effect on deoxidizing; with the adoption of the deoxidier, the contents of nonmetal impurities in the steel can be reduced, the form of the impurities can be changed, the molten steel can be purified, the liquidity of the molten steel can be improved, the molten steel is smooth in continuous casting; and the continuous casting water ports are out of nodules, thus the continuous casting can be smoothly carried out, the service performance and the service life of steel can be improved and prolonged, and the cost of steelmaking can be reduced.

Owner:芜湖县天海耐火炉料有限公司

Manufacturing method of steel

The invention provides a manufacturing method of steel. The method comprises the following steps: roughly melting molten steel; adding a pre-deoxidizer into a steel ladle in a process from tapping to ladling; and refining the molten steel in an LF (ladle furnace), wherein aluminum is added into the molten steel to perform precipitation and deoxidization in a process of refining the molten steel in the LF furnace; adding the synthesized residues into the ladle to heat; and adding a diffusible deoxidizer into the ladle to perform strengthened deoxidization after the synthesized residues are molten. According to the manufacturing method of steel in the invention, the molten steel can be purified, clogging of a water gap is effectively prevented, and the casting performance of the molten steel is improved. The manufacturing method of steel in the invention is simple, convenient and easy to operate, and has a good application prospect.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Silicon-manganese-calcareous shale deoxidizer and preparation method thereof

The invention discloses a silicon-manganese-calcareous shale deoxidizer and a preparation method thereof. The silicon-manganese-calcareous shale deoxidizer comprises the following raw materials in parts by weight: 40-50 parts of quartz sand, 15-20 parts of black manganese ore, 5-10 parts of celestine, 50-60 parts of limestone, 20-30 parts of calcareous shale, 5-10 parts of scrap iron, 10-20 parts of coal ash, 10-15 parts of vermiculite and 5-10 parts of sepiolite. The silicon-manganese-calcareous shale deoxidizer disclosed by the invention has the advantage that a formula is reasonable and the calcareous shale, the scrap iron, the coal ash, the vermiculite and the sepiolite are adopted as raw materials, so that the deoxidizer has a good deoxidizing effect, the content of nonmetal impurities in steel can be reduced, the forms of the impurities can be changed, molten steel is purified, the liquidity of the molten steel is improved, the continuous casting process of a molten steel blank is smooth, no accretion is generated at a continuous casting nozzle, thus, the smooth casting production is facilitated, the use performance of the steel is improved and the service life of the steel is prolonged; and the steelmaking cost is reduced.

Owner:芜湖县天海耐火炉料有限公司

Composite silicomanganese deoxidizer and preparation method thereof

The invention discloses a composite silicomanganese deoxidizer and a preparation method thereof. The composite silicomanganese deoxidizer consists of the following raw materials in parts by weight: 30-35 parts of quartz sand, 10-20 parts of black manganese ore, 15-20 parts of irony shale, 60-65 parts of fly ash, 10-15 parts of bauxite, 1-2 parts of salt and 30-40 parts of vermiculite. The composite silicomanganese deoxidizer is reasonable in formula, and the fly ash, the bauxite and the salt are added in the raw materials. The composite silicomanganese deoxidizer has good deoxidizing effect, and can reduce the content of non-metallic inclusions in steel and change the forms of the inclusions so as to purify the liquid steel and improve the molten steel liquidity. The molten steel continuous casting billet process is smooth, and nodulation does not occur at a continuous casting gate, so that smooth production of continuous casting is facilitated the usability of the steel is improved, the service life of the steel is prolonged, and the steelmaking cost is reduced.

Owner:芜湖县天海耐火炉料有限公司

A kind of boron-added high-carbon pure steel electric arc furnace smelting preparation method

ActiveCN108300934BImprove mechanical propertiesReduce contentProcess efficiency improvementElectric furnaceElectric arc furnaceUltimate tensile strength

The invention belongs to the technical field of special steel and smelting technologies thereof, and relates to a method for preparing boron-adding high-carbon clean steel through smelting in an electric arc furnace. The boron-adding high-carbon clean steel comprises the following components of, by mass, 0.67-0.75% of C, 0.15-0.37% of Si, 0.30-0.80% of Mn, no more than 0.012% of P, no more than 0.006% of S, 0.20-0.50% of Cr, no more than 0.30% of Mo, no more than 0.30% of V, 0.002-0.100% of B, and the balance Fe and unavoidable impurities. The preparing method comprises the steps of electric arc furnace smelting, LF furnace refining and continuous casting processing. The property result of the steel prepared through the method is as follows, the tensile strength Rm is greater than or equalto 1450 MPa, the yield strength R0.2 is greater than or equal to1350 MPa, plates of the steel are used for sintering saw-blade mother plates, the produced plastic deformation damage is small, the life of the sintering saw-blade mother plates is prolonged, and the steel is low in production cost.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Steel slag recycling technology

InactiveCN109680157AImprove utilizationGuaranteed high temperature performanceProcess efficiency improvementSlagRefractory

The invention discloses a steel slag recycling technology. The steel slag recycling technology comprises the steps that firstly, steel slag is collected; secondly, magnetic separation is conducted oniron-containing raw materials; thirdly, air is introduced to achieve roasting for adjusting components; and lastly, roasted steel slag is used for preparing a refractory material.

Owner:JINGYE STEEL CO LTD

Silicon-manganese-barium alloy deoxidier and preparation method thereof

The invention discloses a silicon-manganese-barium alloy deoxidier and a preparation method of the silicon-manganese-barium alloy deoxidier. The silicon-manganese-barium alloy deoxidier comprises the following raw materials in parts by weight: 30 to 35 parts of quartz sand, 10 to 20 parts of barite, 15 to 20 parts of kaolinite, 55 to 65 parts of coal ash, 10 to 15 parts of waste aluminum powder, 25 to 35 parts of attapulgite, 20 to 25 parts of sepiolite and 20 to 25 parts of black manganese ore. The silicon-manganese-barium alloy deoxidier has rationality in formula; the coal ash, the waste aluminum powder, the attapulgite, the sepiolite and the black manganese ore are added to the raw materials, thus the cost is low. The deoxidier has good effect on deoxidizing; with the adoption of the deoxidier, the contents of nonmetal impurities in the steel can be reduced, the form of the impurities can be changed, the molten steel can be purified, the liquidity of the molten steel can be improved, the molten steel is smooth in continuous casting; and the continuous casting water ports are out of nodules, thus the continuous casting can be smoothly carried out, the service performance and the service life of steel can be improved and prolonged, and the cost of steelmaking can be reduced.

Owner:包头市固阳县双亿化工有限责任公司

A method for smelting zirconium-added high-carbon pure steel in an intermediate frequency induction furnace

ActiveCN108220769BImprove mechanical propertiesReduce contentUltimate tensile strengthInduction furnace

The invention belongs to the technical field of special steel and smelting of the steel, and relates to a zirconium-added high-carbon pure steel medium-frequency induction furnace smelting preparing method. The zirconium-added high-carbon pure steel is composed of components including 0.67 to 0.75% of C, 0.15 to 0.37% of Si, 0.30 to 0.80% of Mn, not larger than 0.012% of P, not larger than 0.006%of S, 0.20 to 0.50% of Cr, not larger than 0.30% of Mo, not larger than 0.30% of V, 0.002 to 0.100% of Zr, and the balance Fe and inevitable impurities. The preparing method comprises the steps of medium-frequency induction furnace smelting, LF, continuous casting treatment and the like. Compared with an existing product, the product has the beneficial effects that the mechanical performance is greatly improved, the tensile strength Rm is larger than or equal to 1400 MPa, the yield strength R0.2 is larger than or equal to 1300 MPa, the board is used for a sintered saw blade mother board, plastic deformation damage is small, the service life is prolonged, and the steel production cost is low.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

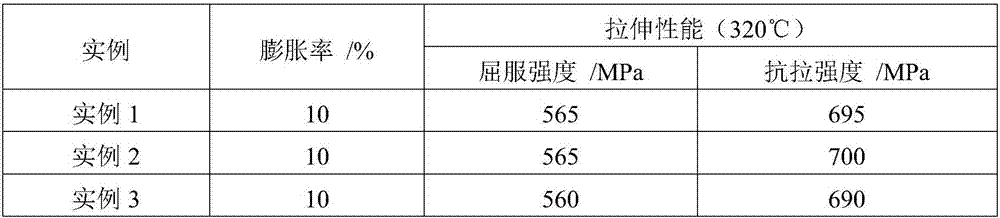

Expansion casing for heavy oil thermal recovery well and manufacturing method thereof

ActiveCN106011638BHigh strengthImprove toughnessDrilling rodsDrilling casingsChemical compositionRare earth

The invention discloses an expansion casing for a heavy oil thermal recovery well and a manufacturing method of the expansion casing. The expansion casing comprises the chemical components of, by mass percent, 0.18-0.32 of C, 0.12-0.32 of Si, 1.1-1.7 of Mn, 0-0.005 of S, 0-0.020 of P, 0.1-0. 6 of Cr, 0.15-0.50 of Mo, 0.10-0.30 of Cu, 0.01-0.05 of Nb, 0.003-0.012 of Ce-La-Y mixed rare earth, and the balance Fe and unavoidable impurities. The manufacturing method comprises the steps of plate coil uncoiling, longitudinal shearing, edge milling, FFX molding, HFW welding, weld joint online heat treatment, weld joint inner and outer burr finishing, whole casing special heat treatment, hot straightening treatment, nondestructive inspection and thread machining. After being subjected to expansion deformation, the expansion casing has high strength, good toughness and heat stability and is suitable for the heavy oil thermal recovery well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Zirconium-added high-carbon pure steel medium-frequency induction furnace smelting preparing method

The invention belongs to the technical field of special steel and smelting of the steel, and relates to a zirconium-added high-carbon pure steel medium-frequency induction furnace smelting preparing method. The zirconium-added high-carbon pure steel is composed of components including 0.67 to 0.75% of C, 0.15 to 0.37% of Si, 0.30 to 0.80% of Mn, not larger than 0.012% of P, not larger than 0.006%of S, 0.20 to 0.50% of Cr, not larger than 0.30% of Mo, not larger than 0.30% of V, 0.002 to 0.100% of Zr, and the balance Fe and inevitable impurities. The preparing method comprises the steps of medium-frequency induction furnace smelting, LF, continuous casting treatment and the like. Compared with an existing product, the product has the beneficial effects that the mechanical performance is greatly improved, the tensile strength Rm is larger than or equal to 1400 MPa, the yield strength R0.2 is larger than or equal to 1300 MPa, the board is used for a sintered saw blade mother board, plastic deformation damage is small, the service life is prolonged, and the steel production cost is low.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Method for preparing silicon aluminium calcium composite deoxidant

The deoxidizer for high-grade steel milting comprises: selecting ferro-silico aluminum, Ca2C and aluminum powder with some weight ratio as the material; breaking the ferro-silico aluminum and Ca2C till some size; dipping the Ca2C into organic oil for given time to take out and mix with the aluminum; then adding ferro-silico aluminum to stir evenly. This product has well desulfurization effect to reduce non-metal impurity and change inclusion shape, prolongs steel service performance and time, and can replace traditional product.

Owner:安阳市龙泉华贯冶金厂 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com