Silicon-manganese coal ash deoxidier for steelmaking and preparation method thereof

A technology of fly ash and deoxidizer, which is applied in the field of steelmaking, can solve the problems of high cost and unsmoothness, and achieve the effect of smooth process, reduced content and lower steelmaking cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: silicon-manganese fly ash deoxidizer for steelmaking, the parts by weight of its composition raw materials are: quartz sand 100, calcareous shale 12, fly ash 22, fluorite 12, charcoal 4, waste aluminum powder 7, Attapulgite 28, black manganese ore 12.

[0011] The preparation method of the silico-manganese fly ash deoxidizer for steelmaking comprises the following steps: weighing each raw material according to the weight of the constituent raw materials, putting them into a submerged arc furnace for smelting, the smelting temperature is 2100-2500°C, and the smelting time is 2-3 Hours, broken to 70-90 mm, remove impurities, that is the finished product.

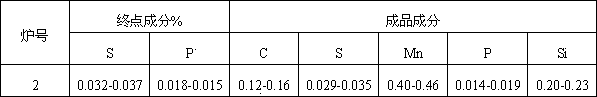

[0012] The following is the deoxidation test, the test steel is low carbon steel, used in 2# furnace, 1.36kg / t steel

[0013] Hot metal conditions:

[0014] [S]S% [P]% 0.039-0.032 0.190-0.152

[0015] Deoxygenation result:

[0016] serial number furnace number Addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com