A zirconium-added high-carbon, micro-alloyed high-strength carbon pure steel and its preparation method

A micro-alloying and high-strength technology, applied in the direction of manufacturing converters, improving process efficiency, etc., can solve problems such as harmful elements, high content of inclusions, limited mechanical properties, plastic deformation of plates, etc., to reduce the content of inclusions, The effect of low production cost and small plastic deformation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In the second aspect, the present invention provides a method for preparing the above-mentioned high-strength carbon pure steel. The method is a production process with converters, RH (or VD) furnaces, LF furnaces, continuous casting, etc. as the main equipment, and is carried out by blast furnace molten iron. Products are prepared by powder spraying and desulfurization pretreatment, converter with pure steel scrap, double slag removal of P technology, slag blocking and tapping for carbon increase, RH (or VD) degassing, LF furnace refining temperature composition adjustment, continuous casting and other treatment methods; The method includes the following steps:

[0043] Step 1. Desulfurization pretreatment of molten iron: Spray desulfurization powder into the molten iron in the molten iron tank for desulfurization treatment, and then perform slag removal treatment to obtain desulfurized molten iron. The mass percentage of sulfur in the desulfurized molten iron is less t...

Embodiment 1

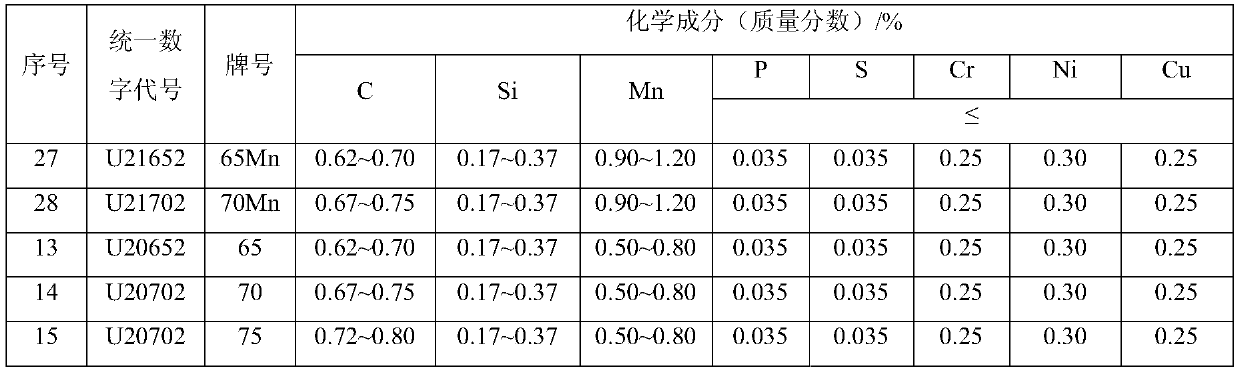

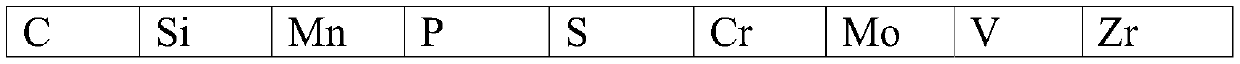

[0074] The high-strength carbon pure steel of the present embodiment is composed of the following mass percentages:

[0075] C Si mn P S Cr Mo V Zr 0.70% 0.27% 0.30% 0.006% 0.003% 0.35% 0.15% 0.15% 0.06%

[0076] The balance is Fe and unavoidable impurities.

[0077] The preparation method of the high-strength carbon pure steel of the present embodiment comprises the steps:

[0078] (1) Hot metal desulfurization pretreatment: the molten iron that desulfurization powder is sprayed into molten iron tank carries out desulfurization treatment at 1400 ℃, then carries out slag removal treatment, obtains desulfurized molten iron, and the mass percent of sulfur in this desulfurized molten iron is less than or equal to 0.0020%. The desulfurization powder is a mixture of lime powder and metal magnesium powder with a mass ratio of 25:1.

[0079] (2) Add slagging agent in advance: add 1 / 3 of the total mass of slagging agent (lime) into the converter. ...

Embodiment 2

[0108] The composition ratio of the high-strength carbon pure steel of the present embodiment is the same as that of Example 1; its preparation method is all the same as that of Example 1 except steps (2) and (3).

[0109] In this embodiment, steps (2) and (3) in Example 1 are replaced by the following operations: the slagging agent is added into the converter in two parts, and the above-mentioned desulfurized hot metal and scrap steel are added to the converter for blowing treatment, mainly in the removal of P During the period, within 1-3 minutes after the start of the above-mentioned blowing treatment, add the first part of slagging agent to the converter, and control the temperature of the blowing treatment to about 1560°C; if the temperature of the molten steel in the converter is higher than 1580°C, it can be Add pellets to the molten steel to cool down. After the dephosphorization-based period, the P content in the molten steel is within 0.008wt%. The molten steel at thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com