Integral forming device for convex points at surface of cloth

A technology with integrated bumps and forming devices, which can be used in fabric surface trimming, textiles and papermaking, and thorn patterns, etc. It can solve the problems of poor convex forming effect and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

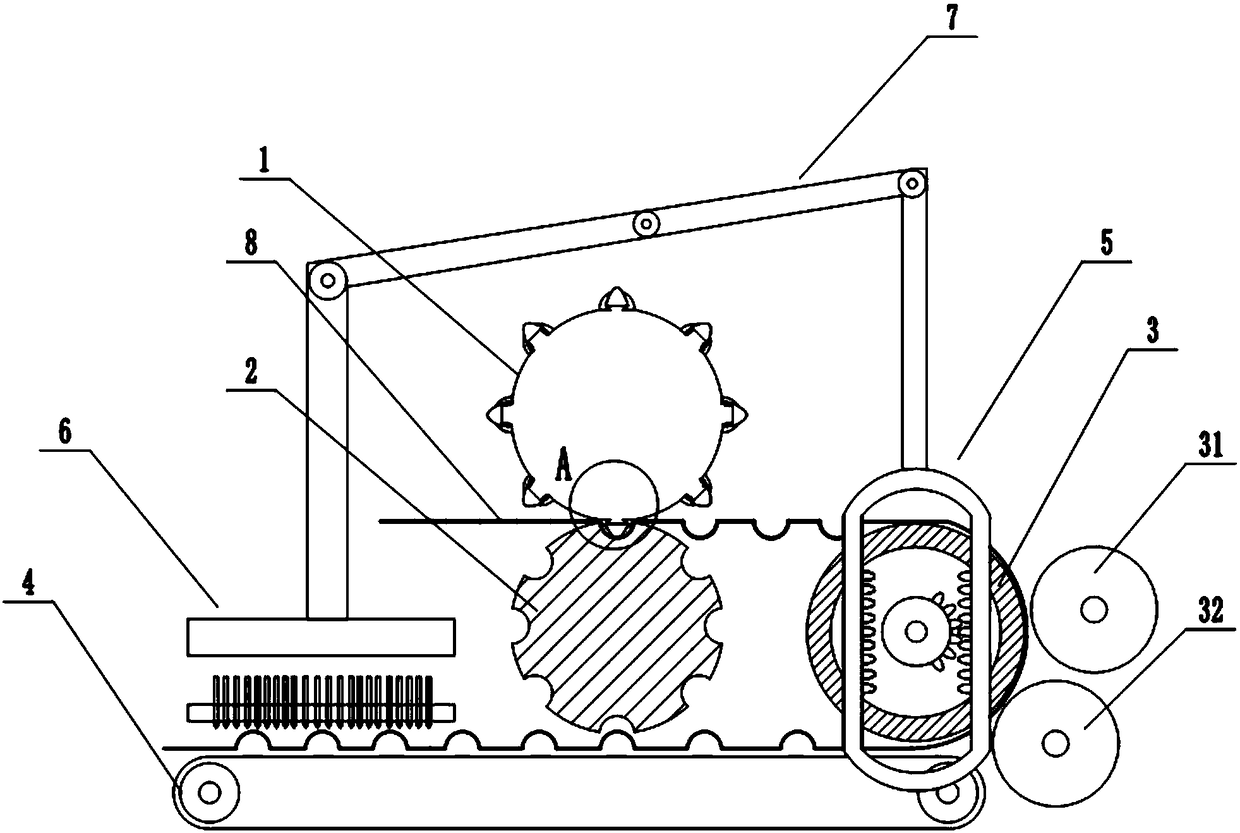

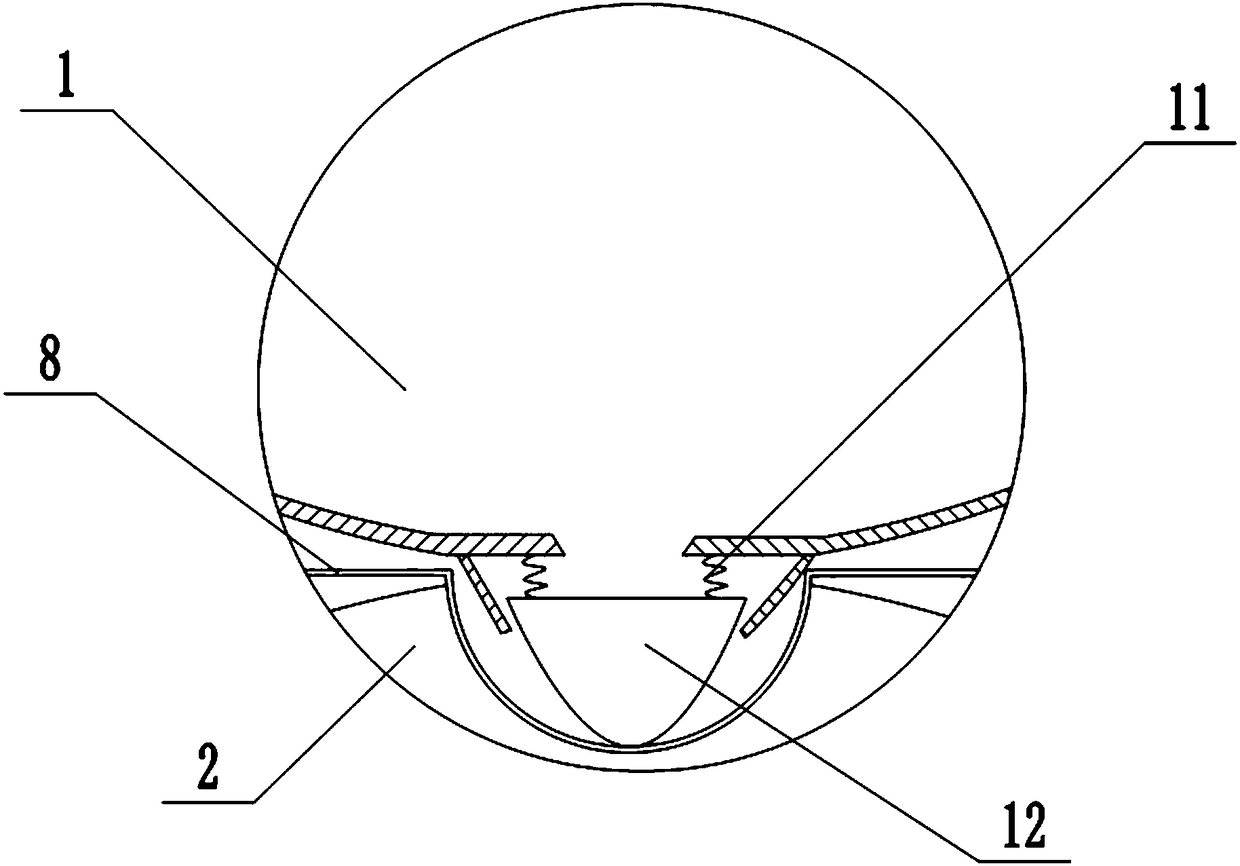

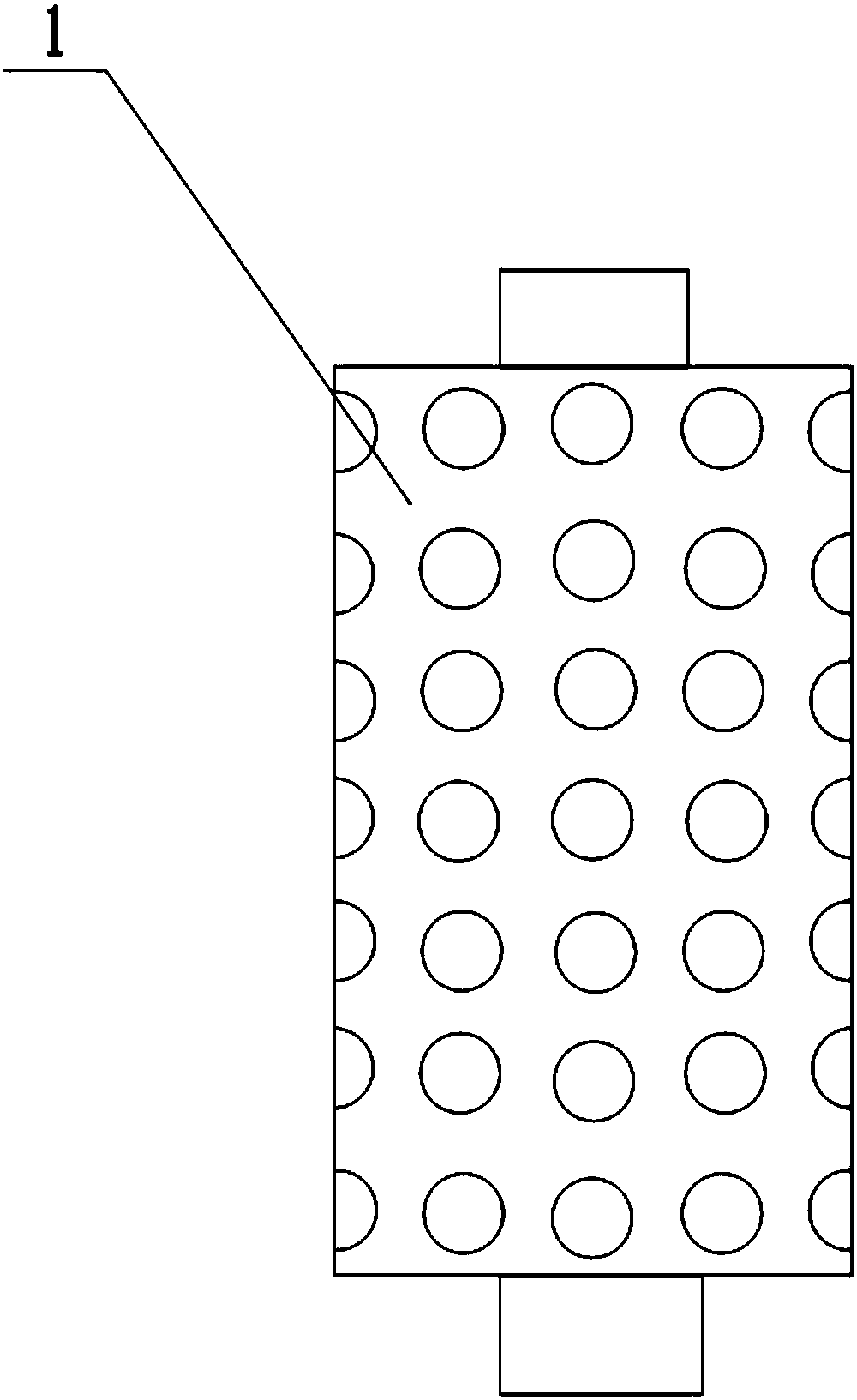

[0022] The reference signs in the accompanying drawings of the description include: upper feed roller 1, spring 11, block 12, lower feed roller 2, first guide roller 3, second guide roller 31, third guide roller 32, conveyor belt 4, Reciprocating device 5, frame body 51, half gear 52, extrusion device 6, first flat plate 61, second flat plate 62, needle tube 63, swinging device 7, lever 71, push rod 72, cloth 8.

[0023] The embodiment is basically as attached Figures 1 to 6 Shown: a device for integrally forming convex points on the surface of cloth, including a frame, which is equipped with upper and lower feeding rollers 1 and lower feeding rollers 2 corresponding to the upper and lower sides. The lower feeding roller 2 is connected with a transmission device, and the upper feeding roller There is a cavity inside the roller 1, and molten wax liquid is injected into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com