Overall drainage construction method of extra-large garbage dump

A construction method and garbage dump technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of heavy landfill tasks, difficulty in site selection and cost of new landfill sites, and high drainage pressure. Achieve the effects of reducing landslides of garbage dumps, good overall drainage effect, and reducing silting problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

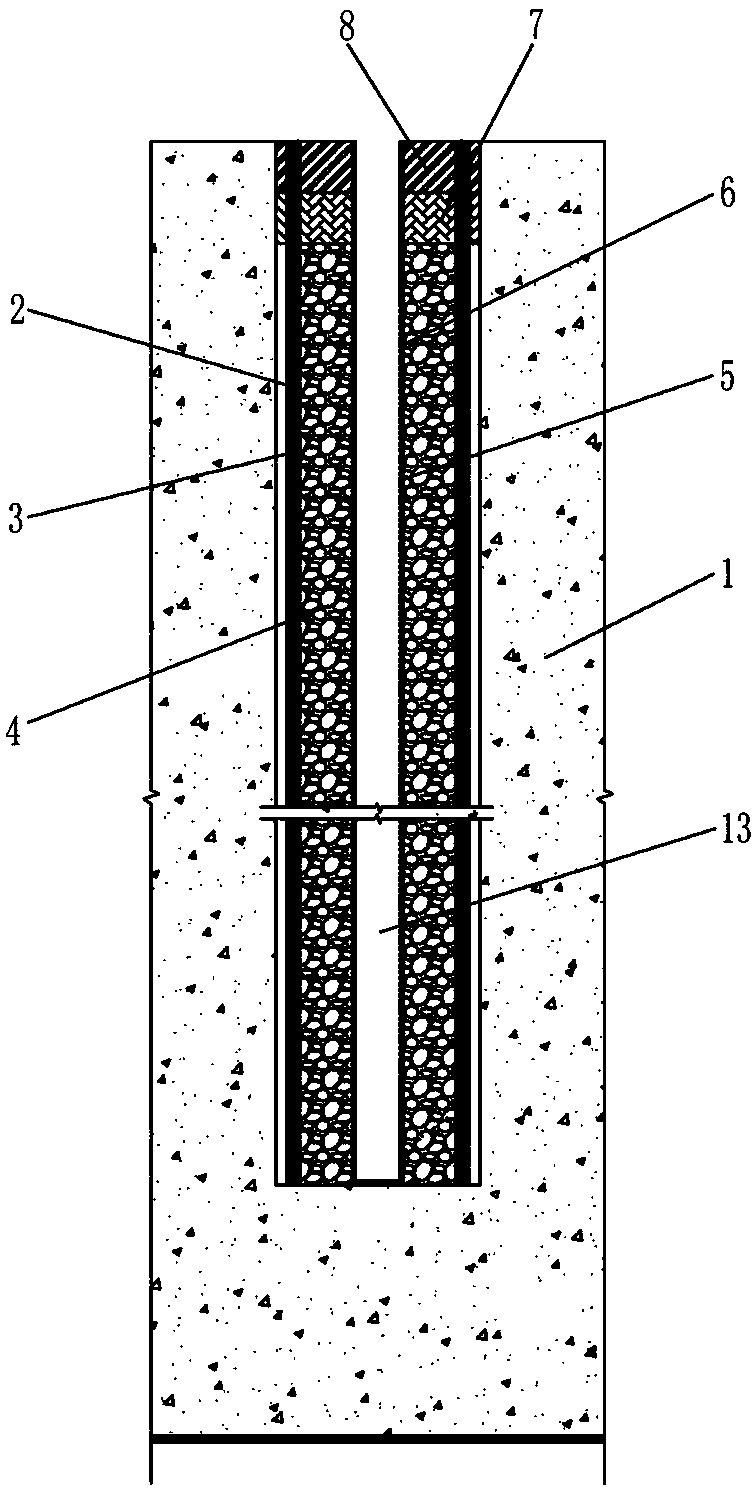

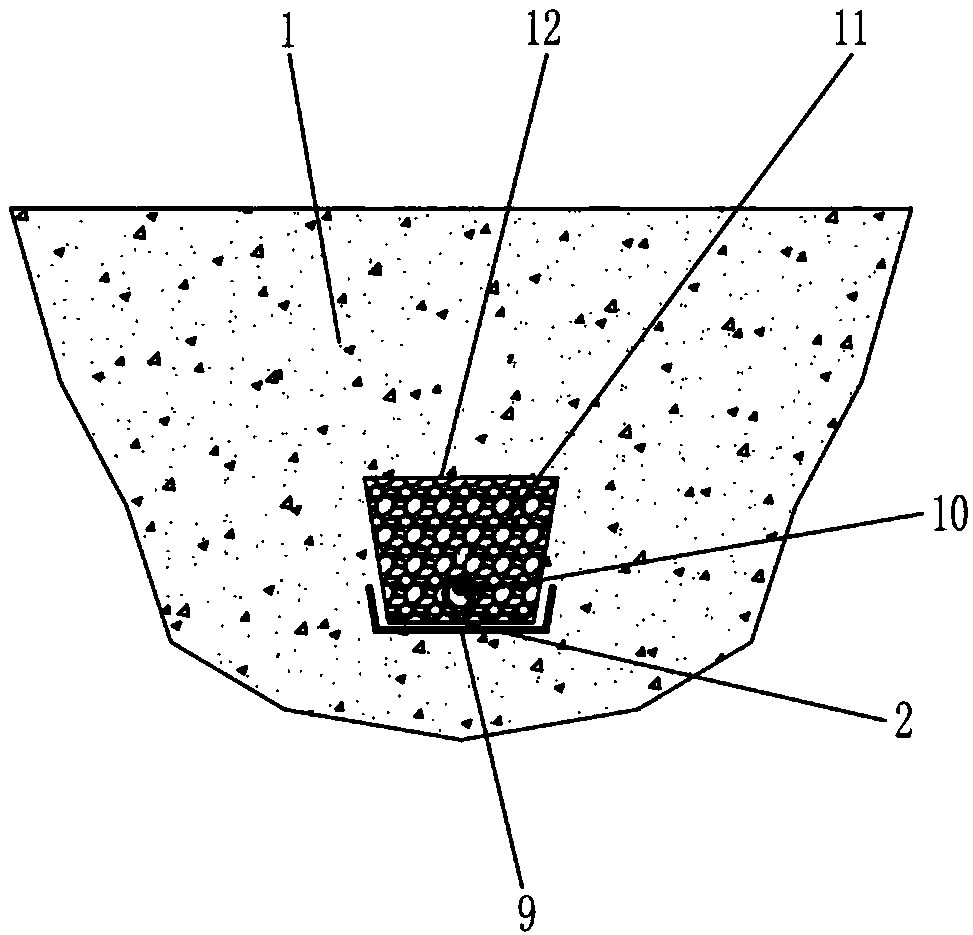

[0016] The overall drainage construction method for super-large garbage dumps includes double-layer composite shaft construction and multi-layer wrapped blind ditch construction.

[0017] refer to figure 1 , the diameter of the double-layer composite shaft is 1000mm, and the depth of the well is 25m. Before construction, workers wear labor protection products to prevent biogas poisoning, clean up garbage masks and waste pipelines, and lay steel boxes for mechanical walking on the garbage dump body 1; then Move the rotary excavator along the steel plate box to the designated position to drill a hole, install a casing on the upper part of the hole to prevent the hole from collapsing, and clean up the drilled garbage in time; wrap the steel cage 3 with a tiled geogrid 2, and put it vertically into the well hole 13 In the process, wrap the galvanized steel pipe 6 with a geotextile 5 and place it in the reinforcement cage 3 accurately; then use a hopper to put the crushed stone lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com