A method of continuous mining in an open-pit mine

A mining method and technology for open-pit mines, which are used in open-pit mining, surface mining, and earth-moving drilling, etc., can solve the problems of unstable material flow and high equipment investment, and achieve the effect of improving equipment efficiency and effective operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] "Up" and "down" in the present invention are based on the orientation or positional relationship shown in the drawings. Take the two steps responsible for mining by a single wheel bucket as an example. The higher step is the upper step (upper level), and the lower step is the lower step (lower level).

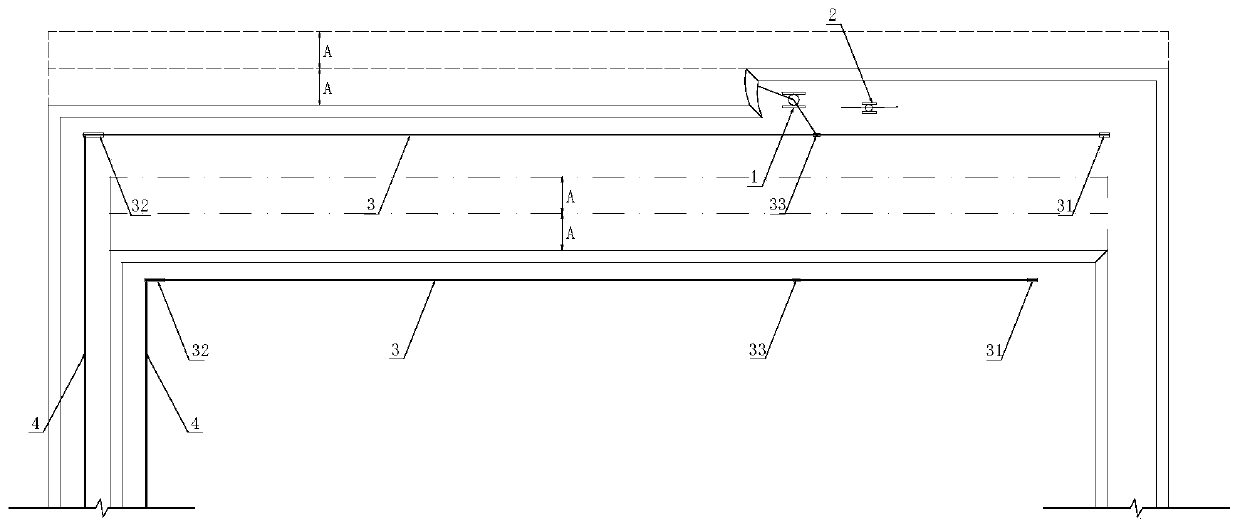

[0037] Figure 1 to Figure 9 A schematic of a cyclic process is shown. Specifically, such as figure 1 , the bucket wheel excavator 1 excavates the first excavation zone from the tail 31 of the belt conveyor to the head 32, and when the excavation zone is exploited, the bucket wheel excavator unloads directly to the receiving trolley 33.

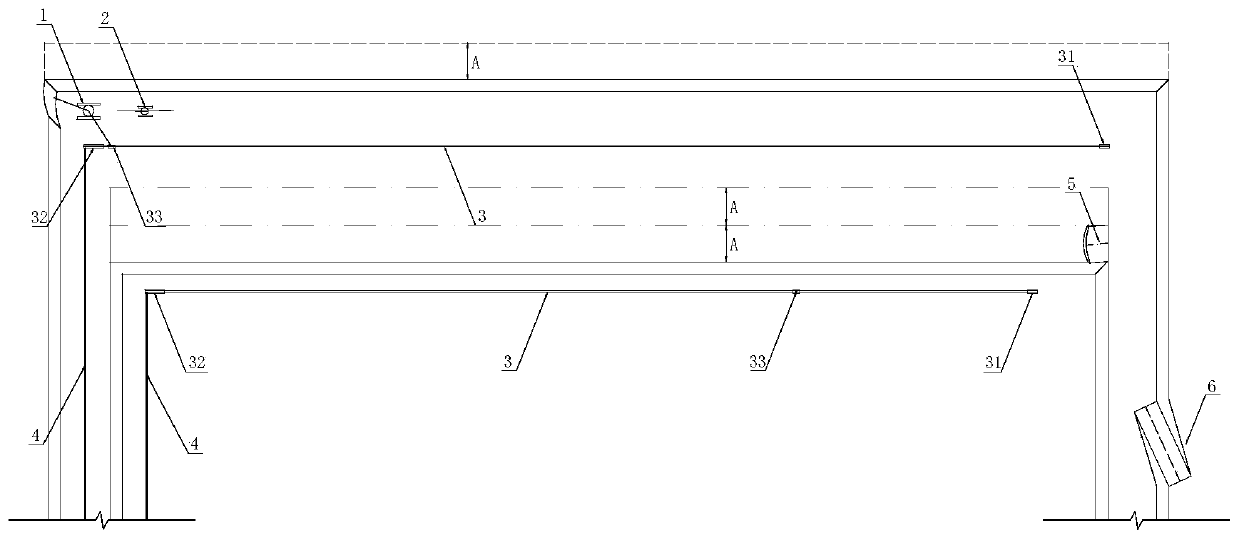

[0038] Such as figure 2 When the bucket wheel excavator 1 reaches the position of the head 32 of the belt conveyor, the first mining belt a is finished. The ramp 5, this part of the excavated material is transported out of the stope through the side-side auxiliary transportation channel.

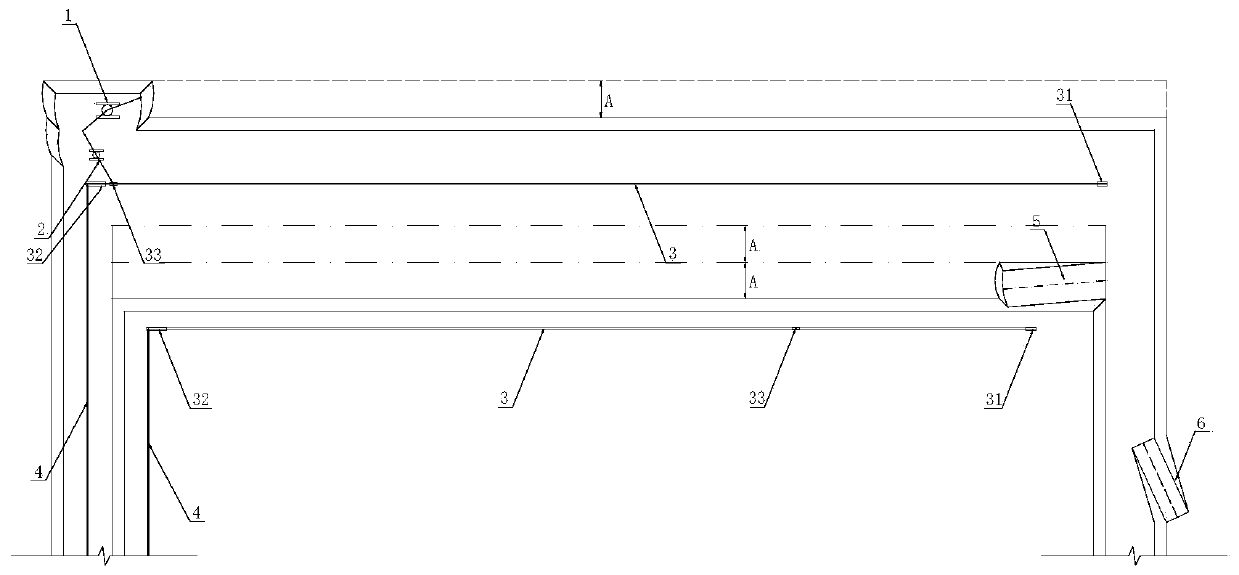

[0039] Such as image 3 , the bucket whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com