Engine air intake and exhaust system and method

A technology of air intake and exhaust and engine, which is applied in the direction of engine components, machines/engines, charging systems, etc., can solve the problems of not reaching the theoretical value of fuel combustion, emission not up to standard, and single form, etc., to increase the air intake speed And the intake air volume, the effect of increasing the exhaust gas exhaust velocity and exhaust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

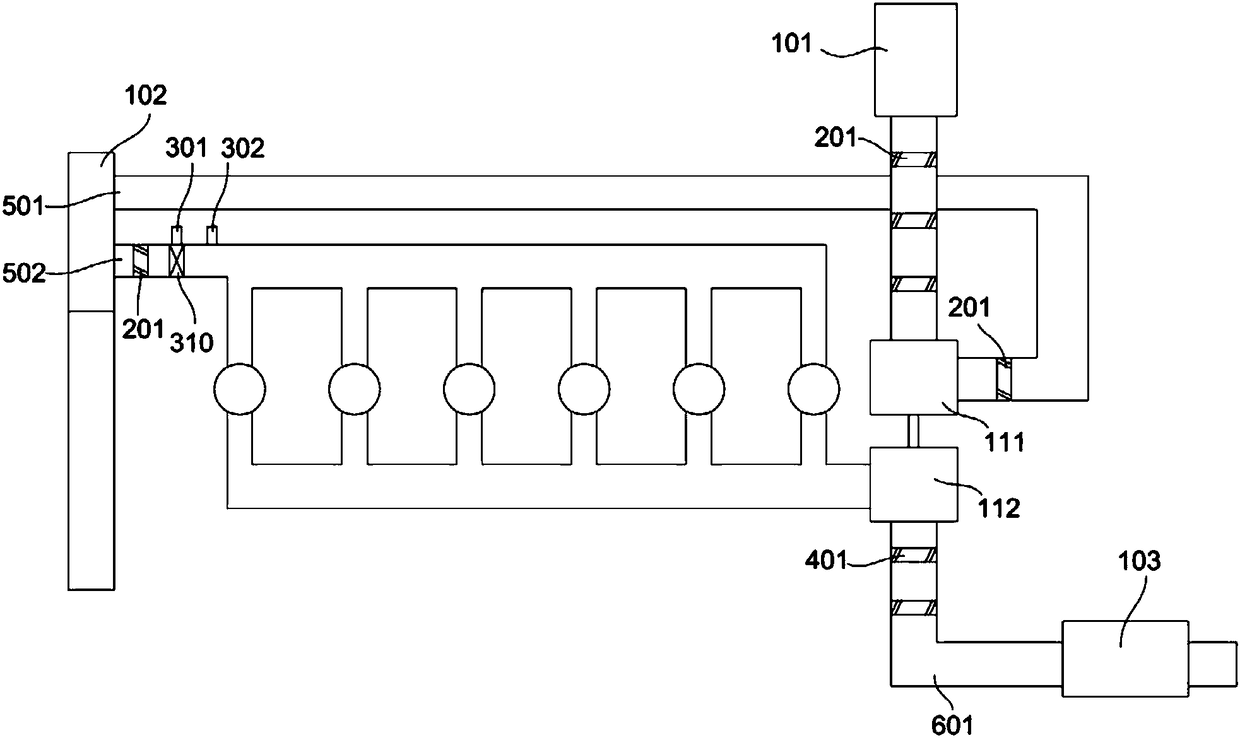

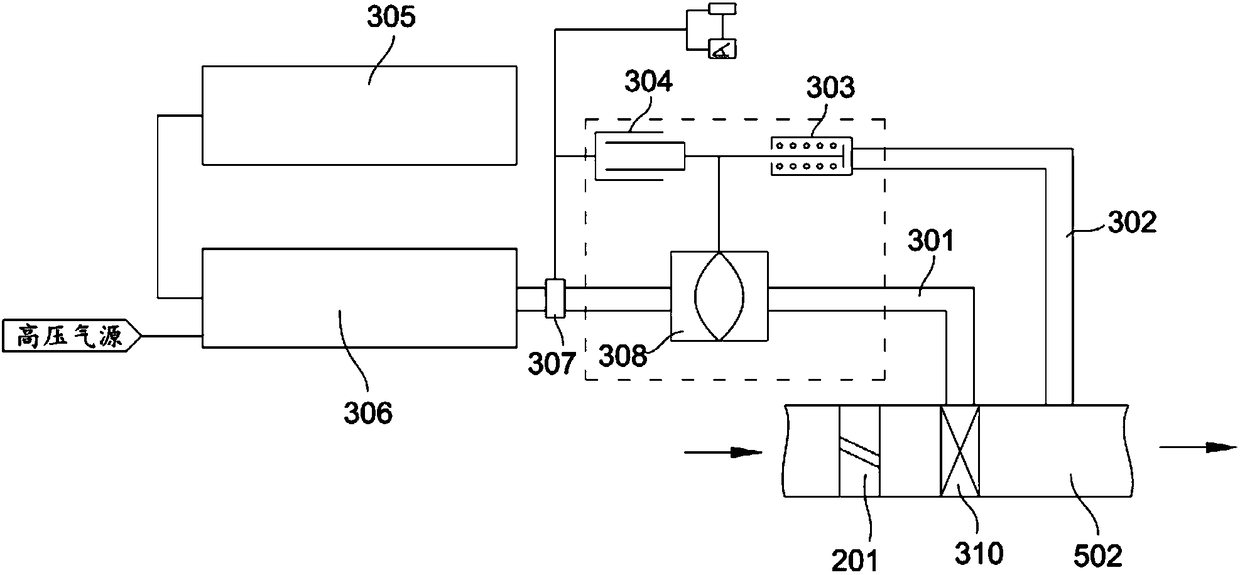

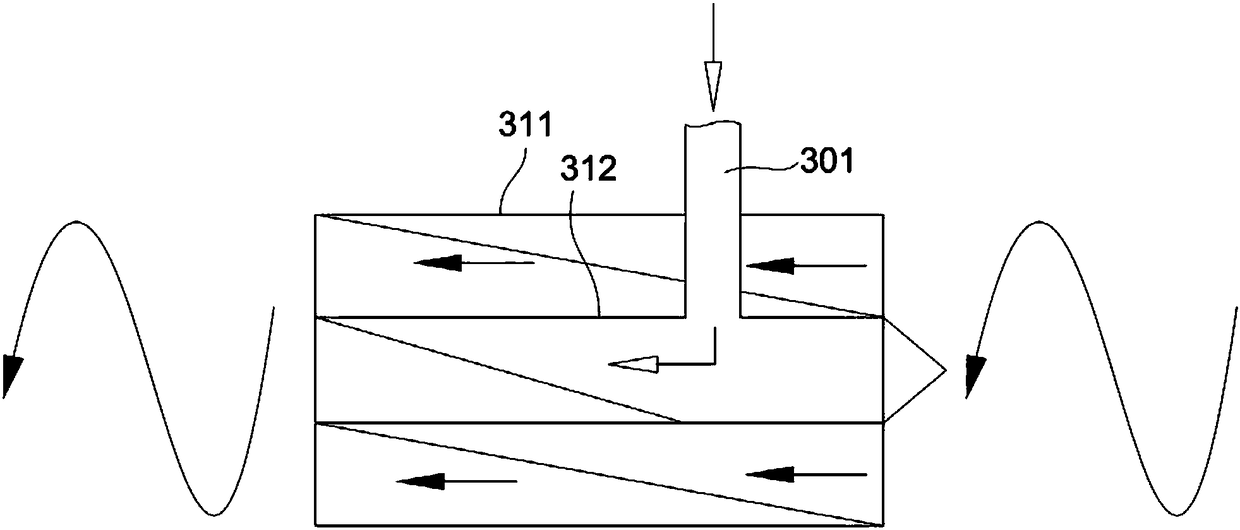

[0046] refer to Figure 1-4 , the engine intake and exhaust system of the present invention includes an intake unit, an exhaust unit and an additional air supply unit, the engine of this embodiment is a turbocharged engine, and the intake unit includes an air filter 101, a compressor of a supercharger The impeller 111, the intercooler 102 and the intake manifold, three intake spoilers 201 are arranged in the first intake pipe 501 between the air filter 101 and the compressor impeller 111 of the supercharger, and the supercharger An intake spoiler 201 is arranged in the first intake pipe 501 between the compressor impeller 111 and the intercooler 102, and an intake spoiler 201 is arranged in the second intake pipe 502 between the intercooler 102 and the intake manifold. An air intake spoiler 201 forms an engine air intake spoiler group through spoilers at three positions. The exhaust unit includes an exhaust manifold, a turbocharger turbine wheel 112 and a muffler 103. In term...

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 is that this embodiment is for a non-turbocharged engine.

[0065] The air intake unit includes an air filter 101, an intake pipe is connected between the air filter 101 and the intake manifold, and three air intake spoilers 201 are arranged in the intake pipe. Along the airflow direction, the connecting portion of the extra air supply pipe 301 and the intake pipe is located at the rear end of any one of the air intake spoilers 201 . The air entering from the air filter 101 passes through the intake spoiler 201 to achieve acceleration, and at the same time realizes the effect of supercharging and maintaining pressure. The injected high-oxygen gas is mixed and finally enters the engine block for combustion. Due to the increased intake speed and the oxygen content of the incoming air, the fuel in the engine block burns more fully and effectively improves Improve the combustion efficiency of fuel, so that the engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com